Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Structure of lithium battery winder:

Lithium battery winding machine is an automatic equipment, which is mainly composed of core winding, winding system, winding system, battery tabs welding system, tension control device, deviation correction system, PLC control, etc.

The working principle and function of each structure of lithium battery winding machine:

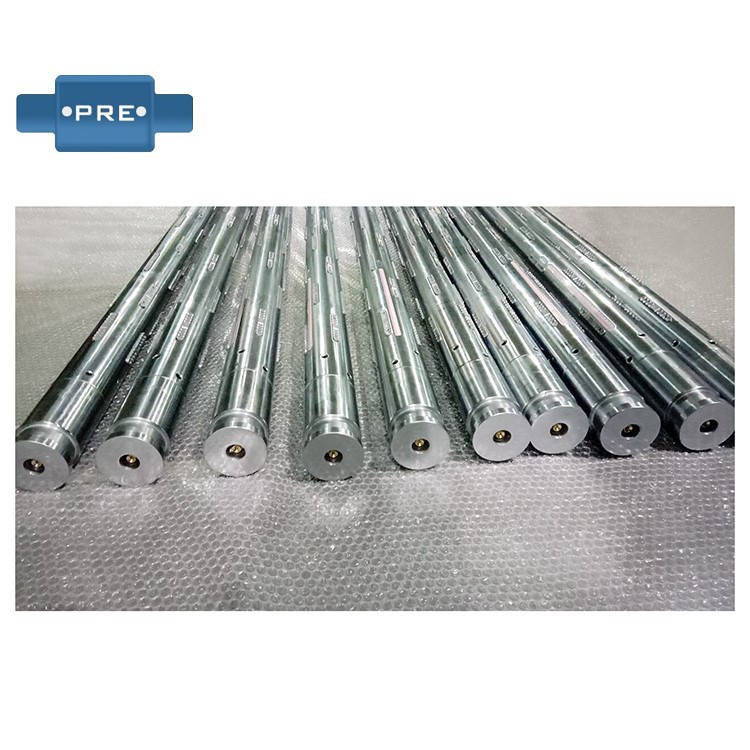

1. Core Core: As a core part of the whole process, core core plays a vital role on this equipment. It is mostly made of aluminum or steel, and the surface is coated with nickel or chromium to enhance its corrosion resistance.

2. Winding system: This system is the core part of the equipment, which is composed of servo motor, reducer and drum. With precise servo motor control, the material is wound according to a set path.

3. Winding system: When the winding is completed, the winding system will retract the reel for the next use.

4. Battery tabs welding system: During the winding process, the battery tabs welding system works at the same time to accurately weld the tabs and foils.

5. Tension control device: The function of this device is to control the tension of the material throughout the process to ensure consistency.

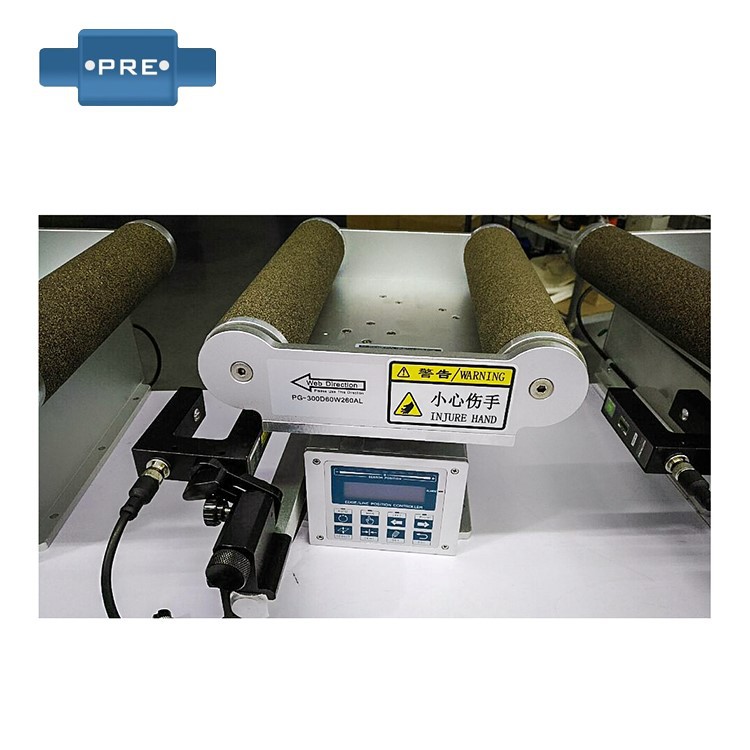

6. Guiding system: The function of the guiding system is to maintain the precise alignment of the material during the winding process.

Lithium battery winding machine general failure and maintenance methods:

1. Failure: The positive and negative electrode suction plates of the winding machine have not yet reached the supply guide plate after suction.

2. Fault: hit manual, pressing the start button is invalid.

3. Fault: the positive CV motor does not turn.

4. Failure: positive and negative RB does not rise after falling the suction sheet.

5. Fault: negative CV motor overheating alarm.

6. Fault: abnormal diaphragm unwinding motor.

7. Fault: the speed of the diaphragm unwinding motor is too fast and not slow.

8. Failure: the tension claw has reached the lower limit, and the sensor has sensed but cannot be reset or cut away.

9. Failure: the needle coil motor does not rotate.

10. Failure: The negative CV motor does not rotate.

11. Failure: the product discharge motor does not turn.

PRE Co., Limited has been in the material coil winding and unwinding machinery accessories industry for more than 20 years, such as air inflatable shafts, rollers, web guiding systems, tension control systems, magnetic powder brakes, pneumatic brakes, magnetic powder clutches, pneumatic clutches, etc.

Before production, we will check all important details with customers, and before shipment, we will check the appearance of each product, whether the inner packaging and outer packaging of the product meet the standards of long-distance transportation. After shipment, we will track the logistics of the goods to assist the goods to reach the customer smoothly and in time. After customers start using the products, we provide comprehensive after-sales service and guarantee.