Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Custom air expanding shafts require the following information to be provided to the supplier:

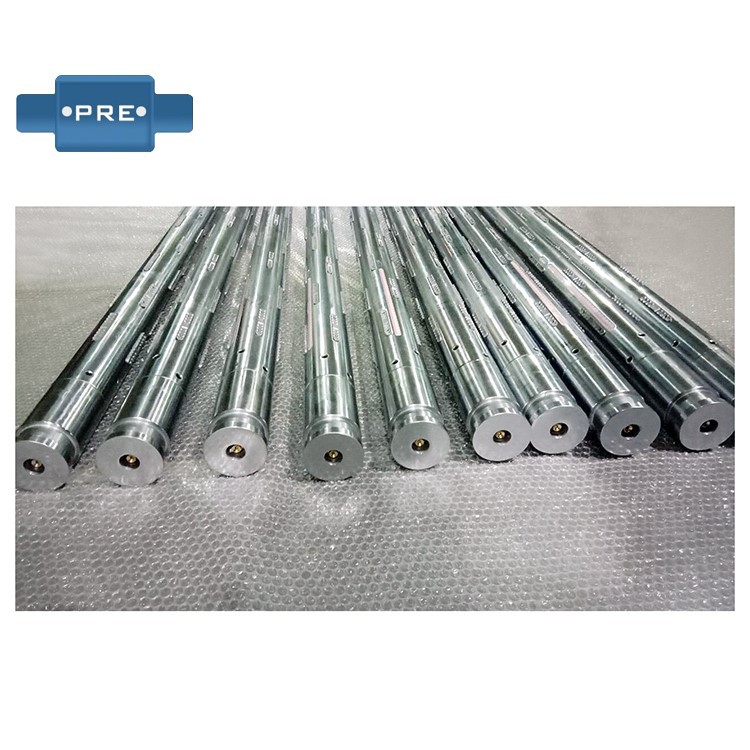

1. Choose the right material. According to the use environment and requirements, different materials can be selected, and the commonly used materials are stainless steel and aluminum alloy.

2. Select the specification size. Select the required specifications, determine the length and diameter of the inflatable shaft, etc.

3. Design load: It is necessary to provide the maximum load and torque data of the bearing to ensure the service life and durability of the shaft.

4. Need to communicate with the manufacturer about the weight, accuracy, and nozzle position of the inflatable shaft.

5. Processing technology: It is necessary to provide the processing method of the shaft, such as cold working or hot working, and provide relevant processing drawings.

6. Surface treatment: According to the use environment and requirements, different surface treatment methods can be selected, such as enamel, alumina film, oxidation dyeing, etc., which is an important factor affecting the appearance and durability of the inflatable shaft.

7. Quantity and delivery time: It is necessary to provide the quantity and delivery time of the inflatable shaft that needs to be customized so that the supplier can arrange the production plan and delivery.

8. If it is to replace the old inflation shaft, it will be clearer to provide pictures or sketches of the old expansion shaft.

In short, providing accurate and complete information can ensure that the quality and performance of the customized leaf/lug type/multi bladder /slip inflatable shaft achieves the desired results.