Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

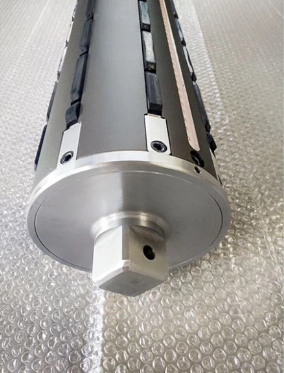

Meaning of Air Expandable Shaft:

It is a kind of special winding and unwinding shaft, that is to say, after high pressure inflation, the surface of the shaft can be protruding, and after deflation, the surface part of the shaft quickly retracted is called the air-expandable shaft.

The principle of air-expanded shaft:

Although there are many different names for pneumatic shafts, the working principle is the same. Air expansion shaft, air expansion sleeve is extremely convenient and quick to use, only need to provide their own air source, air pressure control in the range of 6-8kg/cm2, the need to lock the external parts (such as round paper tube), as long as the air gun to the air expansion shaft on the air nozzle inflatable can be accomplished, the top of the external parts (such as round paper tube), the need to relax the paper unloading, with a hand to press down on the nozzle on the slip of the external parts (such as round paper tube) can be taken out. When it is necessary to unload the paper, the outer part (e.g. round paper tube) can be removed by pressing down on the air nozzle.

Uses of the pneumatic expansion shaft:

The use of the air expansion shaft is very wide, where there are winding, unwinding, slitting machines, can be applied to the air expansion shaft, even including the light metal industry. Such as: air expansion shaft is mainly used in printing equipment: sun board machine, flexographic printing machine, gravure machine, trademark printing machine, etc.; other machinery: coating machine, leather machine, sizing machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, blown film machine, foaming machine, laminating machine, embossing machine, papermaking machine, non-woven fabrics, fabric inspection machine, hot stamping machine, battery equipment, and other related machinery. The use of supporting.

What are the types of air expandable shafts?

At present, the most common types are: keyed shafts, plate type shafts, through-length keyed shafts, and sliding shafts.

Keyed Expansion Shafts, also known as Cross-keyed Expansion Shafts: High load bearing capacity, single keystroke projection.

Plate Expansion Shafts: Uniform expansion, balanced force, 6 plates expanding at the same time, uniform force.

Through-length keyed shafts: the keystrip is different from the cross key, it is a keystrip projection on the expansion part, with high precision of runout tolerance and high load-bearing capacity.

Slip Differential Shaft: Slip Differential Shaft is not the same as the ordinary air expansion shaft, the slip differential shaft structure is special, composed of multiple slip differential ring, slip differential ring is equipped with ball, the purpose is to use the slip differential shaft on the principle of each slip differential ring slipping, mainly used in the slitting machine rewinding, special occasions are also used in the unwinding, so that more than one roll of material on the shaft, always maintain a stable tension of rewinding and unwinding.

How to customize the right air expansion shaft:

1, air expansion shaft (air shaft) is generally based on the needs of the actual application to make, there is no standardized parts, but also according to the actual needs of different types of choice. Common types are aluminum alloy air expansion shaft, expanding key type air expansion shaft as well as vane type air expansion shaft, etc. Some distinguish between metal and non-metal.

2, the expansion shaft is generally designed by the user's own drawings and provide to the expansion shaft manufacturer, at the same time to be attached to the customized requirements, such as the weight of the expansion shaft, the material and its precision requirements and other aspects. Manufacturers will be based on the drawings provided by the user and other requirements for technical assessment, and then production.

3, air expansion shaft as a special special winding and unwinding equipment, usually with magnetic powder brake, magnetic powder clutch, tension controller supporting the use. The application is very wide, such as coating machinery, slitting machinery, cutting machinery, laminating machinery, laminating machinery, blown film machinery, papermaking machinery, nonwoven machinery, fabric inspection machinery and other machinery winding and unwinding system.

How to maintain the air expansion shaft?

1. Check carefully whether the tools, workpieces and accessories can be placed evenly, and whether the lines and pipes can be attached intact;

2. Stop cleaning after application so as to check the application of the air expansion shaft in time, especially the oil, water and electricity leakage of the machinery;

3. Do not add some unclean oil when refueling the machine to ensure the normal operation of the machine.

Previous: Multi-airbag Through-key Inflatable Shaft

Next: What Information Do I Need To Provide To Chinese Suppliers For Custom Inflatable Shafts?