Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Definition of satellite rotary press:

Satellite rotary printing machine is the latest rotary printing technology, which has the advantages of fast printing speed, good stability and high printing quality. The equipment uses advanced printing technology to meet the requirements of today's market for high quality, high performance and efficiency.

With oil feeding system, inkjet temperature control system, automatic level adjustment system and other intelligent functions, it can ensure that the quality of published products is steadily improved, and at the same time, the printing efficiency can be greatly improved.

When printing operations, it is necessary to ensure the stability and accuracy of printing quality. The guiding system exists to solve this problem.

The structural composition of the guiding system and its working principle in the printing process:

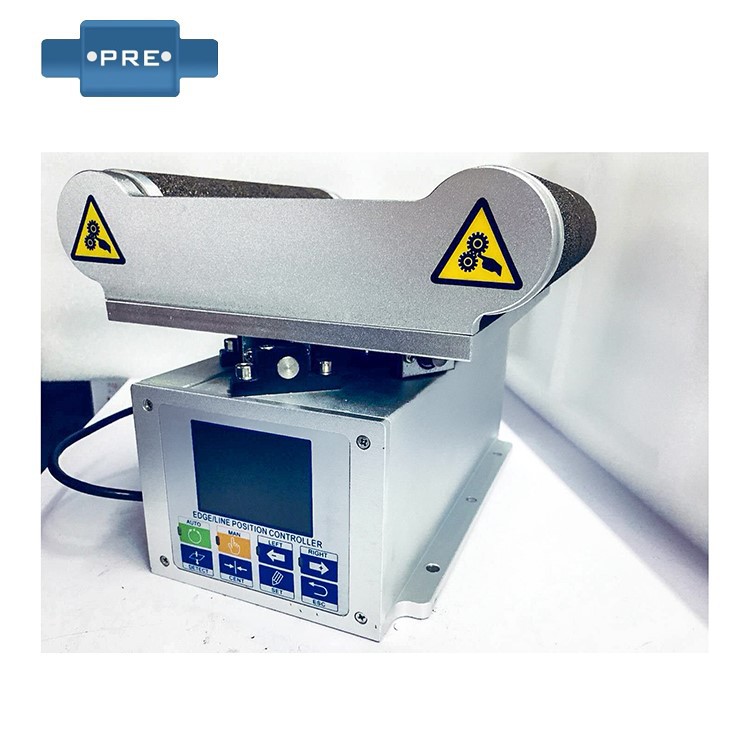

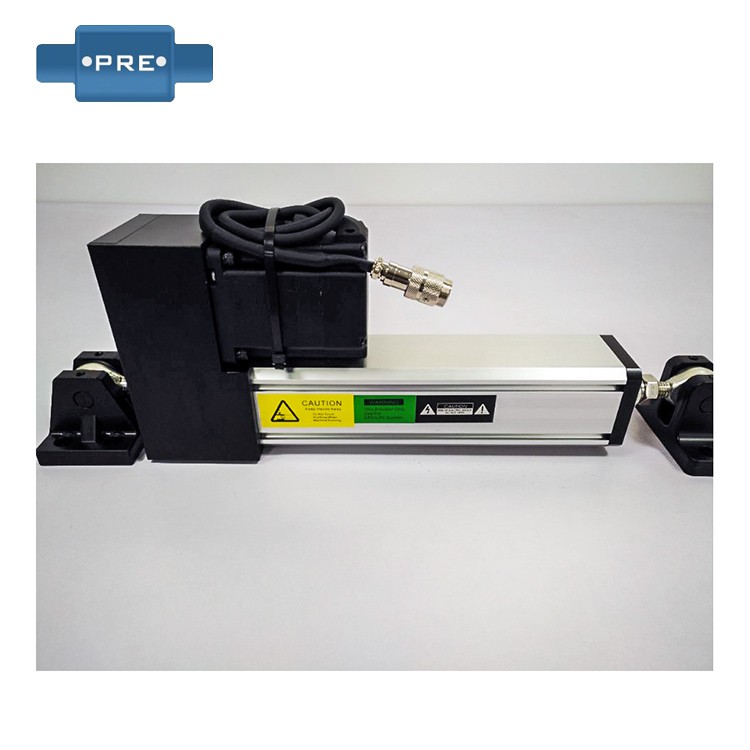

It is generally composed of a guiding controller, a guiding sensor, a guiding driver, a guiding frame, etc.

During the printing process, the position deviation of the paper is detected in real time by a photoelectric sensor and the signal is transmitted to the guiding controller. The guiding controller generates the corresponding control signal through calculation, and then controls the electric drive mechanism or hydraulic system to make the roll in a balanced state to eliminate the deviation of the paper.

Operation steps of the guiding system:

1. Adjust the probe: Adjust the distance between the probe and the take-up rack to a suitable position according to the required detection accuracy and width.

2. Select the correction mode: select the correction mode according to the printing machine model and specific paper characteristics, including paper width, quality, thickness and speed.

3. Adjust the guiding controller: according to the actual situation, adjust the parameters of the guiding controller, such as probe detection speed, correction speed and pressure.

4. Turn on the printing machine: After the guiding system is set, turn on the printing machine to start printing, at this time the guiding system will automatically perform the correction operation according to the set parameters.

Functions and features of the guiding system:

1. Support three working modes: line chasing, edge chasing, and medium.

2. Support photoelectric sensor, ultrasonic sensor, CCD sensor.

3. Intelligent detection of sensor parameters, no need to calibrate the sensor in most environments.

4. Automatic stroke measurement, no mechanical limit switch.

5. No overshoot integral variable PI adjustment algorithm, high precision, quick response, smaller error.

6. Ultra-high-speed 500 microseconds (0.5 milliseconds) response speed.

7. Analog sensor signal 12-bit AD sampling, 700,000 sampling speed per second.

8. The use of FIR digital filter and return difference filter has stronger anti-interference ability and more stable signal.

9. DC servo motor pushes the ball screw.

10. All system status parameters are power-down memory.

11. Store 10 sets of different material parameters, it is convenient and fast to switch materials.

12. Chinese Simplified/Chinese Traditional/English three-language menu operation.

13. Humanized operation, fast and easy.

14. Support Modbus bus and PLC/man-machine interface network control.

Solutions to common faults in servo motor guiding systems:

1. The electric eye does not track, that is, the plastic film appears uneven and uneven.

Solution: The sensitivity of the electric eye is reduced, or the dust is covering the spectacle lenses, please clean the electric eye or remove the electric eye.

2: The sensitivity of the system software is insufficient, under normal circumstances, the plastic film should vibrate at the electric eye, and then adjust the sensitivity adjustment knob on the control cabinet, so that the place is just to flutter and do not move at that time is the best situation. The electric eye switch power supply light is not on.

Solution: If the electric eye can still work normally, only the indicator light is not on, this is only the display light is broken, can be applied again or sent to the enterprise for maintenance.

3. Photoelectric correction cannot track some tones of the system.

Solution: Under normal conditions, LED blue, white, red, etc. have color shift phenomenon, generally unfamiliar with the primary color, that is, blue light is the worst to identify blue, yellow light is more difficult to identify milky white. At this time, please press the optical eye SET button for three seconds to relax, let the optical eye fully adjust the lamp source, or must adjust the control cabinet sensitivity knob to increase the sensitivity.

4. The photoelectric correction system software control cabinet manipulates the electric actuator to only go to one side and cannot go back.

Solution: This phenomenon is generally the destruction of the control cabinet power tube, inspection method: use the manual method to see whether the electric actuator only goes to one side, such as the manual type only walks on one side, to replace the power tube. If the manual type can go on both sides, but only go to one side after the electric eye is connected, the electric eye is bad or the control cabinet is positive/reverse wrong, and the electric eye is replaced again or the control cabinet is adjusted (it is proposed to send it to the overhaul).

5. Manual or fully automatic does not work.

Solution: If the left and right manual keys are not in posture when the manual type, if the 5A fuse tube is intact, it can be judged that the tube is damaged and needs to be replaced (it is proposed to send it to the maintenance).

6. The control cabinet does not work.

Solution: The switching power supply is not added, check whether the 2A/5A fuse tube is burned (broken), or not very good to touch. (Proposal sent to overhaul).

7. Equalization is not allowed.

Solution: Adjust the equalization resistor multi-turn (5 turns) resistor, if the orientation is wrong, it cannot be adjusted to equalization from beginning to end. Or two resistors are broken. (If in turn, it is still impossible to adjust the imbalance, and the proposal is sent to the overhaul).

Previous: The Application Of Deflection Correction System in Blown Film Machine

Next: Lithium Battery Winding Machine Failure And Maintenance