Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The winding and unwinding process is very important to industrial production, which can improve production efficiency, reduce production costs, ensure product quality, promote enterprise development, and bring important guarantees for the sustainable development of enterprises.

The winding and unwinding process in plastic film, printing, packaging materials, paper have applications in many other industries. Its specific operation requires the following mechanical spare parts:

1. Unwinding and unwinding equipment: including winding and unwinding machine, air expanding shaft, winding and unwinding roll, etc. These machines are used to put away materials smoothly and avoid unnecessary difficulties and damage.

Among them, the commonly used air expansion shaft is leaf type air expansion shaft, lug type inflation shaft, through long key type air expansion shaft(multi bladder type air shaft), and the specific required size can be customized to PRE Co.,Limited.

If the existing inflatable shaft size cannot meet the existing needs, the inflatable shaft adapter can be customized to meet the conversion of different coil shafts.

2. Cutting equipment: In the process of material processing, it is necessary to cut for different products to ensure the accuracy of product size. Cutting equipment includes cutting machines, knives, etc.

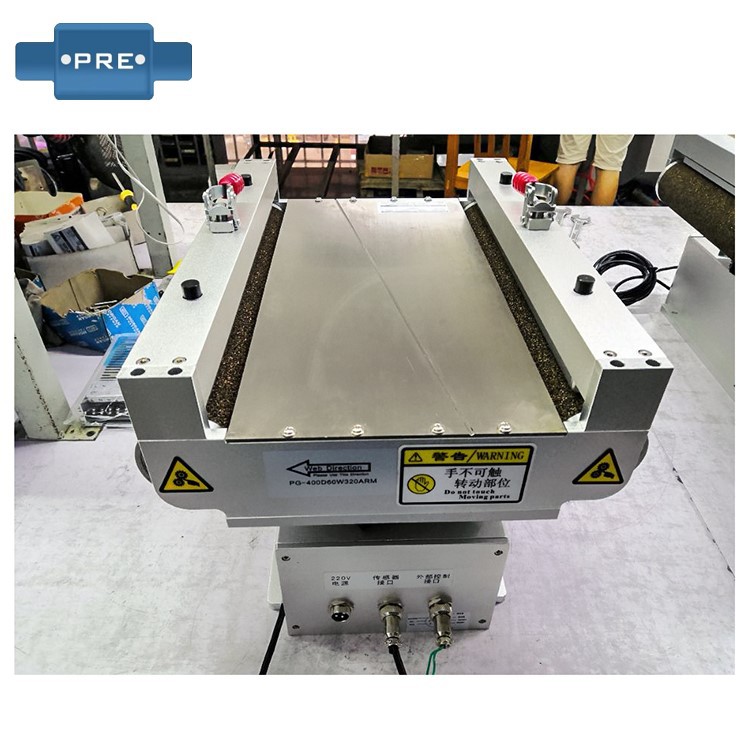

3. Web guiding system: In order to avoid the deviation of the material during the retracting process, a guide device is required to maintain the proper position of the film. Including: guiding controller, guiding sensor, rectifier actuator, etc.

Among them, there are two commonly used guiding controllers: EPC edge controllers and LPC line controllers. There are two commonly used guiding sensors: ultrasonic sensors and photoelectric sensors. The rectifier is available in 6 models at PRE Co.,Limited.

4. Tension control system: to ensure that the quality of materials, such as dimensional accuracy (thickness, width, cross-section shape, etc.), straightness, winding tightness, shape and material performance, etc. meet the standard requirements. Includes: tension controller, tension sensor, magnetic powder clutch.

Among them, in the process of choosing a tension sensor:

5. Magnetic powder brake or pneumatic brake: its use is also buffer starting or stopping, tension control, continuous sliding, adjusting the operating speed of winding and unwinding equipment, etc.

6. Cutting equipment: used to cut large pieces of plastic film into the required size. Cutting equipment includes cutting machines, tools, etc.

Previous: Lithium Battery Winding Machine Failure And Maintenance

Next: Common Fault Phenomena And Solutions Of Automatic Guiding Device