Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

A deskew system is a technical operation used by a manufacturer to keep the sides of the web neat and consistent at all times during the coating, printing, punching, laminating, slitting or other web winding processes. Its widespread use has brought great benefits to the industry, and deskew control has led to automated control in industries such as iron and steel, corrugated cardboard, textiles, printing, labels, tagging, papermaking, plastic film, construction materials, cables, rubber, tyres, and Nonwoven corrugated paper processing and other industries appear automated control.

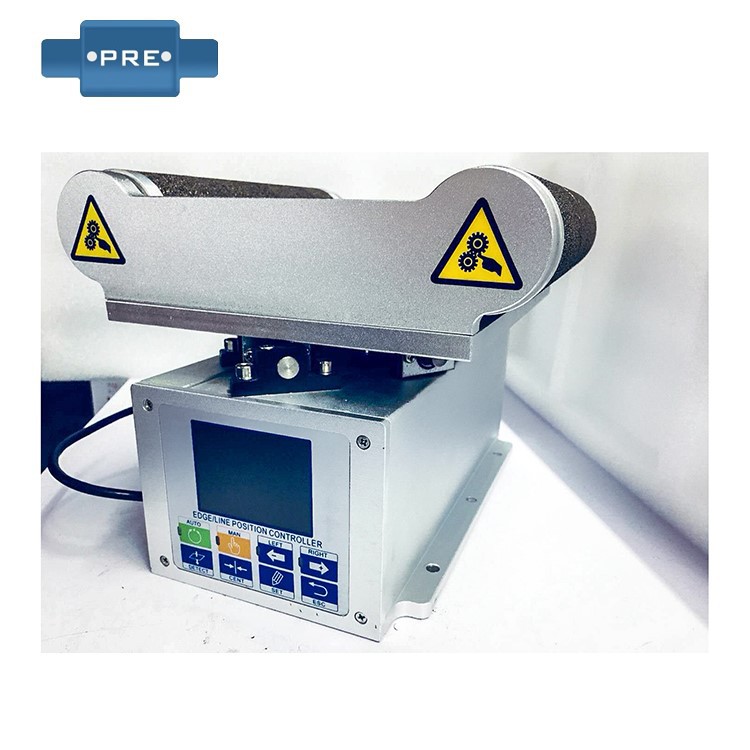

The web is monitored by infrared/ultrasonic/laser/visible light emitted by the web guiding sensor B, which sends signals to the controller A. When the controller detects a drift in the web's position, the web is corrected according to the controller's pre-set commands by controlling the web guiding frame C through the driver D. The web is then corrected by the controller A. The web is then corrected according to the controller's pre-set commands. The automatic web guiding system uses photoelectric sensors to detect the edge position of the web, and sends the measured position error signal to the controller, which, after judgement and processing by the control unit, controls the drive motor to correct the web in the deviated position to the correct position.

The FIFE deviation correction system offers several different detection methods: edge detection, line following or centring. The drive system is driven by low-speed synchronous, frequency-controlled, stepper and servo motors, and the drive stroke is strictly proportional to the web offset. The system can also be used with different probes to suit the needs of detecting different coils, e.g. infrared photoelectric, analogue infrared photoelectric, etc.

A guiding system is a key control device in many industrial applications, and choosing the right guiding system is essential to ensure the stability and efficiency of your equipment. This article will provide a detailed buying guide to help you choose the right guiding system.

1. Define your needs:Before choosing a deskew system, you need to clearly define your needs. Consider the type of deviation to be corrected, the required accuracy, the working environment and other factors. This will help you narrow down your choices and find the most suitable system.

Understanding Sensors: At the heart of a guiding system are sensors, which detect deviations and transmit signals to the controller. Understanding the different types of sensors, such as photoelectric sensors, laser sensors, cameras, etc., as well as their characteristics and scope of application, will help you choose the right guiding system.

3、Consider the controller function:The controller is the key component of the deviation correction system, which receives the sensor signals and makes calculations and adjustments. Choose the controller with advanced control algorithm, user-friendly interface and reliability. It should also consider whether the controller supports data logging and remote monitoring functions to meet the actual needs.

4, determine the actuator:The actuator is responsible for adjusting the object according to the controller's instructions. Select the appropriate actuator according to the application requirements, such as electric drives, hydraulic or pneumatic devices. Pay attention to the speed, accuracy and reliability of the actuator.

5、Consider compatibility and expandability:When selecting a guiding system, its compatibility with existing equipment and systems should be considered. If you need to expand the function or increase the number of deflection correction points in the future, make sure that the selected system has the corresponding expansion ability. In conclusion, selecting a suitable guiding system requires a clear definition of requirements and an understanding of the characteristics and scope of application of sensors, controllers and actuators. It is also important to consider compatibility and future expansion needs. By following this buyer's guide, you will be able to select the right guiding system for your application.

a. Pay close attention to avoid installation deviation during installation.

(1) The tightening of the gland should be carried out after the coupling has been corrected, the bolts should be evenly supported to prevent the end face of the gland from being skewed, and the error should not be more than 0.05 mm when checking each point with a plug ruler.

(2) Check the fit clearance (i.e. concentricity) between the gland and the outer diameter of the shaft or bushing, which should be even all around, and the tolerance at each point should be no more than 0.01 mm when checked with a plug ruler.

b. Spring compression should be carried out in accordance with the regulations, not allowed to have too large or too small phenomenon, the required error of 2.00 mm. Too big will increase the end face specific pressure, another speed end face wear. Too small will cause the pressure is not enough to play the role of sealing.

c. After the installation of the moving ring beard to ensure that the shaft can move flexibly, the moving ring pressure to the spring should be able to automatically spring back.

Previous: Why Do We Need A Web Guiding Control System in An Industrial Coil Production System?

Next: The Application Of Deflection Correction System in Blown Film Machine