Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Basic steps for custom inflatable adaptor:

An inflatable bushing is an accessory that is often used in the operation of machinery, especially in some specific industries. With the acceleration of industrialization, the demand for inflatable bushings in the market is also increasing. Factory customized inflatable bushings can meet the individual needs of customers, and at the same time, it can also ensure the quality and performance of products, and provide better support for enterprises.

1. Before customizing the inflatable bushing in the factory, you need to understand the needs and requirements of the customer, including the size, material, hardness, surface treatment of the bushing, etc.

2. Customers can provide corresponding drawings or samples according to their own needs, or provide detailed instructions to the manufacturer.

3. On this basis, the factory will carry out detailed design and inspection to ensure the accuracy and reliability of the products.

4. According to the different needs of customers, the factory will adopt different materials and processes for production. Commonly used materials include high-strength steel, aluminum alloys, copper, stainless steel, etc., and their choice depends on the desired properties and use. Different materials require different production processes, such as forging, machining, welding, quenching, etc.

5. The factory will carry out strict control and testing during the production and processing process to ensure that the inflatable bushings produced meet the quality standards and customer requirements.

6. At the same time, the factory will also track and monitor the products after they are marketed to ensure the excellent performance and long-term reliability of the products.

In short, factory custom inflatable bushings need to understand the needs of customers and select appropriate materials and processes for production and processing. This process requires extremely strict controls and inspections to ensure the quality and performance of the product while providing optimal support to the customer.

Application of inflatable shaft sleeve on inflatable shaft:

The inflatable bushing is a new type of bushing with a wide range of applications, especially on the inflatable shaft. The inflatable shaft is a special shaft with an inflatable effect, which is widely used in printing, packaging, textile, plastic products and other industries. Because this shaft has the advantages of good shaft positioning and no shaking, it can be used in fields that require high-precision printing and transfer.

An inflatable bushing is a type of bushing made of a special material, which is special in that it is filled with gas inside. This type of bushing has the following advantages over conventional bushings:

1. Lightweight: Since the inside is filled with gas, the inflatable bushing has the characteristics of light weight. This also means that inflatable bushings can save the machine's energy consumption, which in turn reduces production costs.

2. Good adaptability: inflatable bushings are suitable for different shaft diameters and applications under various different working conditions. This bushing does not require any mechanical adjustment and can be adapted to different process needs.

3. High precision: The inflatable bushing can ensure the accuracy and stability. It can maintain high-precision positioning under high-speed operation and heavy-load conditions to ensure product quality.

4. Simple structure: The inflatable bushing does not have too many mechanical parts, so there is no additional maintenance cost. It can be mounted directly on the inflatable shaft, which is very convenient.

By applying an inflatable bushing to an inflatable shaft, higher print quality, longer sleeve life, and higher productivity can be achieved. In addition, the inflatable bushing can also improve the stability and safety of the machine.

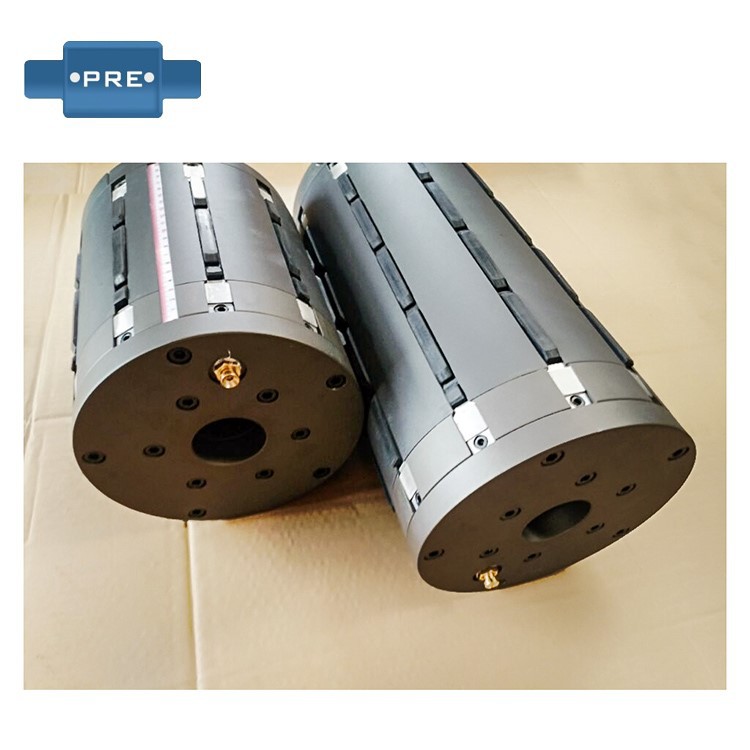

Structure of inflatable sleeve:

The inflatable sleeve is a common seal, also known as the pneumatic sealing ring, which is inflated with air or nitrogen, and the inner ring wall is close to the shaft journal or hole wall, which can play a good sealing role under strong vibration or centrifugal force. The air sleeve is mainly composed of front sleeve, rear sleeve, cylinder, inner tube, air bag, convex keyboard and other parts. The expansion set is made of high-quality aluminum, with oxidized surface, high-quality airbags and fast inflators. Good sealing effect, long service life and easy maintenance.

The working principle of the inflatable sleeve and related precautions:

The internal structure of the inflatable bushing is composed of two annular parts, the upper and lower parts, and the gap between them is filled with high-pressure gas, which is sealed to form a gas film at the friction site to alleviate friction and wear, and also reduce the loss of energy, making the mechanical equipment more efficient.

When the equipment is running, the gas in the bushing expands under the influence of the pressure and temperature of the object's movement, and this expansion will cause a certain gap between the bushing and the shaft, thus forming a gas film, which reduces the contact area between the bushing and the shaft, thereby reducing friction and wear. At the same time, the effect of the gas film causes the gas to be dampened between the bushing and the shaft, thus absorbing the impact forces generated by factors such as machine vibration and external noise.

When using an inflatable bushing, it is necessary to pay attention to the problem of tightness, because it is impossible for the gas to remain in the sleeve forever, and it needs to be replenished in time, otherwise it will lose the air film effect. In addition, factors such as high temperature, high load, and high viscosity will affect the stability and reliability of the air film effect, so in the process of use, we must pay attention to the selection of appropriate materials and technical parameters to ensure its long-term stable working performance.

Features of the inflatable sleeve:

Different materials and shapes can be selected according to different use environments and requirements, such as pure rubber, plastic, iron and stainless steel, etc., and can also meet different needs according to different sizes and shapes. Compared with other seals, the sealing performance of the inflatable sleeve is more stable, will not produce leakage and looseness, and also has a good vibration absorption effect, which can effectively reduce machine noise and vibration, and improve the stability and service life of the equipment.

Inflatable sleeve clamp (inflatable drum) product specifications:

It is divided into key inflatable sleeve and plate inflatable sleeve. Commonly used specifications are: 3 inches to 6 inches, 3 inches to 8 inches, 3 inches to 10 inches, 3 inches to 12 inches. After inflation, the diameter rises by 8mm. The length is 200mm, 250mm, 300mm, 400mm, 500mm, etc. (The length can be ordered according to customer needs, and the length is not limited)

Application scenarios of inflatable sleeves:

The application scenarios of inflatable sleeve are very wide, such as in mechanical transmission, it can be used for the sealing of rotor journal, flywheel journal and shaft sleeve to prevent oil and gas leakage and dust ingress, and ensure the normal operation of equipment; In the hydraulic system, it can be used to seal the piston of the hydraulic cylinder, piston pump and oil pump to effectively prevent the leakage of hydraulic oil and ensure the safe and stable operation of the system; It also has a wide range of applications in the fields of petrochemical, food processing and medical devices, and can meet different sealing requirements.