Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Web guiding systems are critical control equipment in many industrial applications, and choosing the right web guiding system is critical to ensure the stability and efficiency of the equipment. This article will provide a detailed buying guide to help you choose the right web guiding system.

1. Define requirements: Before choosing a correction system, you need to clearly define your needs, considering the type of deviation that needs to be corrected, the required accuracy, the working environment and other factors. This helps to narrow down the options and find the best guiding system for you.

2. Understand the sensor: The core of the correction system is the sensor, which can detect deviations and pass the signal to the controller, understand the different types of sensors, such as photoelectric sensors, laser sensors, cameras, etc., as well as their characteristics and scope of application, which is helpful to choose the appropriate correction system.

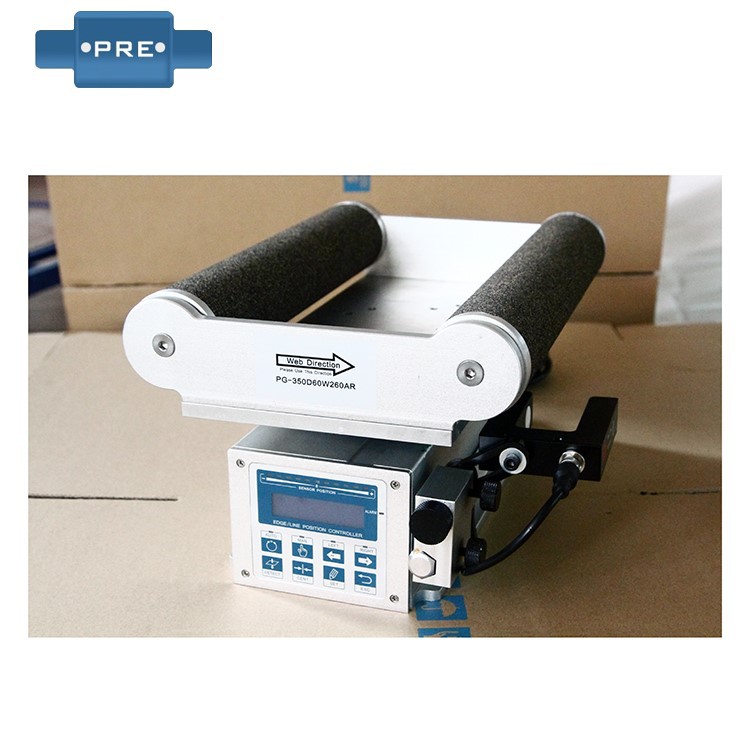

3. Consider the controller function: The controller is a key component of the deviation correction system, which receives the sensor signal and calculates and adjusts, and selects the controller with advanced control algorithms, user-friendly interface and reliability. Consideration should also be given to whether the controller supports data logging and remote monitoring capabilities to meet actual needs.

4. Determine the actuator: The actuator is responsible for adjusting the object according to the instructions of the controller, and selecting the appropriate actuator according to the application requirements, such as electric drive, hydraulic or pneumatic device, etc. Pay attention to the executive agency

Speed, precision and reliability.

5. Consider compatibility and scalability: When choosing a correction system, it should be considered to be compatible with existing equipment and systems, and if you need to expand the function or increase the number of deviation points in the future, ensure that the selected system has the corresponding expansion ability. In summary, selecting the right guiding system requires a clear definition of requirements and an understanding of the characteristics and scope of application of sensors, controllers, and actuators. At the same time, it is important to consider compatibility and future expansion needs. By following this buying guide, you will be able to select the right guiding system for your application.

According to the type of control, the automatic deviation correction device system can be divided into:

1. Automatic Deviation Correction Device Edge Position Control Type (E.P.C)

2. Automatic Deviation Correction Device Line Position Control Type (LPC)

3. Automatic deviation correction device centerline position control type (C.PC)

Types of guiding modes for the automatic guiding control system:

The automatic deviation correction control system is the basic component of the closed-loop control system, the controller, the sensor, and the linear guiding mechanism constitute the closed-loop control, first the deviation correction sensor detects the edge or line of the coil, reads the actual position of the coil and the signal shift of the set position, converts the offset into a proportional electrical signal, and then sends the electrical signal to the controller, the controller amplifies the signal, and outputs it to the / linear zone mover after calibration, and the linear driver drives the deviation correction number to the mechanism according to the size of the signal, and restores the coil to the set position. The drive signal of the current drive is only proportional to the coil deviation, allowing the guiding system to provide accurate control for a wide range of different coils.

The guiding mode depends on the degree of material processing, unprocessed materials can only be guided according to the edge centerline of the material, because these materials have no other comparative properties to refer to, and the processed material has more characteristics when oriented, such as printed lines or contrasting edges. Enables analog or digital guiding sensors to scan the position of the material.

1. Material order correction: According to the left and right edges of the material, use the edge correction sensor for deviation correction.

2. Material centerline correction: According to the centerline of the material, two edge correction sensors are used for deviation correction.

3. Contrast correction: according to a continuous or discontinuous printing line or opposite

The guiding system is widely used in packaging, brushes, labels, building materials, red desire, household paper, plastics, garments, electrical construction, metal processing, non-woven fabrics, tile groove processing and other industries, typical automatic correction control systems include correction controllers, correction sensors, correction frames and drives.

Characteristics of different types of sensors and their application in guiding systems:

Laser sensor is a sensor that uses a laser beam for measurement and detection, and its measurement distance, high precision, and fast speed make it widely used in industrial automation, manufacturing and other fields. In the guiding system, the laser sensor can monitor and control the position and motion state of the object by measuring the reflected laser beam on the surface of the object.

Camera sensor is a device that uses optical image technology for sensing and detection, and its wide observation range, high precision, strong adaptability and other characteristics make it widely used in image processing, visual recognition and other fields. In the deviation correction system, the camera sensor can realize the monitoring and control of the object's position and motion state through the acquisition and processing of the object surface image.

The role and significance of the guiding system in industrial production:

In order to ensure that the transverse position of the substrate is fixed before entering the printing unit, the unit type flexo printing machine often adopts an automatic correction device, which can detect the deviation of the transverse position of a certain edge of the substrate and correct it in time, its accuracy can reach 0.5 mm, generally for opaque materials such as paper and aluminum knots, photoelectric sensors are often used; For thin and transparent materials, ultrasonic sensors are used. Once the substrate enters the printing area and the die-cutting and rewinding area, the stability of its transverse position is ensured by the processing and installation accuracy of the machine itself and the parallelism between the spokes.

1. The deviation correction system plays an important role in industrial production, and its role and significance cannot be ignored. First of all, the deviation correction system can ensure the accuracy and quality of production and processing. In the production process, due to various reasons, the bearing or production line may be deviated, which will lead to a decrease in the accuracy and quality of the production process, and even lead to an increase in the scrap rate. The guiding system can detect the deviation and adjust the bearing position in time, so as to ensure the accuracy and quality of product processing and reduce the generation of scrap.

2. The guiding system can improve production efficiency and reduce costs. The use of a web guiding system reduces downtime and adjustment time, thereby increasing productivity. At the same time, the deviation correction system can avoid the return and rework of products due to poor product processing, and reduce production costs.

3. The deviation correction system can increase production safety and protect the health of workers. The web guiding system can prevent accidents or failures in the production line, avoiding personal injury and equipment damage. At the same time, the tracking system can reduce the impact of noise pollution and vibration on workers, and protect workers' health.

4. The deviation correction system can improve the service life and stability of the equipment. As the production line is constantly running, bearings and other components can wear and age, affecting the service life and stability of the equipment. The guiding system can detect the bearing position and adjust it in time, reduce the wear of the bearing, and thus prolong the service life and stability of the equipment.

Previous: Problems And Solutions To The Web Guiding System

Next: Introduction To Photoelectric Guiding System And Its Application in The Printing Industry