Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

What are the reasons why the inflatable shaft of Chinese manufacturers can be cost-effective?

1. Low production cost: China is a country with a large population and abundant productivity, and has natural advantages in raw material procurement, processing and manufacturing, labor costs, etc., so Chinese manufacturers can take advantage of this advantage to produce high-quality inflatable shafts at a relatively low cost.

2. Strong technical strength: In China, there are many talents with rich experience and technical level, who continue to explore and innovate, use modern scientific and technological means and precision tools, and constantly improve production efficiency and product quality, so that China's manufacturing has been continuously improved.

3. Fierce competition in the industry: In China's inflatable shaft production industry, fierce competition forces manufacturers to continuously improve product quality and cost performance in order to occupy a place in the market. Such a competitive environment can force Chinese manufacturers to constantly innovate and improve in order to produce more competitive products.

4. Strong production capacity: Chinese manufacturers have advanced production equipment and high production capacity, which can quickly respond to customer needs and meet market demand, greatly shortening the delivery cycle and improving production efficiency.

What is the inflatable shaft:

The inflatable shaft, as the name suggests, is the shaft that will swell when inflated. Its special structure is mainly composed of: hollow shaft body, air bag, key bar, shaft head, air valve and other parts.

Use the air pressure of 0.6-0.8Mpa to inflate the air nozzle, the air bag expands, and the key bar is protruded, so as to jam the inner core of the coil sleeved on the outside to avoid slipping when the material is retracted and unwinded. Ensure the smooth progress of the rewinding and unwinding work. It has the characteristics of safe and fast grasping of various cores without wearing, and adopts a bolt-free design to effectively avoid airbag leakage caused by bolt friction, and has the characteristics of convenient operation, fast operation and no damage to the core in practical applications.

How the inflatable shaft works:

The inflatable shaft is a shaft that will be inflated and inflated, and the outer diameter is smaller than the inner diameter of the coiled paper tube, so that it can be easily loaded and unloaded, and the inflatable will support the inner wall to avoid rotation or sliding, and facilitate the unwinding and winding of the coil.

Classification of inflatable shafts:

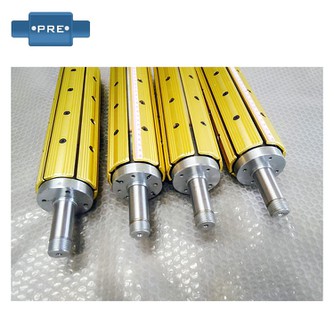

*Inflatable shafts can be divided into key inflatable shafts, plate inflatable shafts, dot inflatable shafts, slip inflatable shafts, air nail shafts, etc.

*According to the material, it can be divided into: steel, aluminum alloy and carbon fiber

* The main types of inflatable shafts are: slat, key and through-bar, and slip inflatable shafts are more commonly used. Let's take a closer look:

1. Slat-type inflatable shaft (inflatable shaft): the expansion part is a plate, which can be applied to machinery with high winding precision or lighter winding items.

2. Key type air shaft (air expansion shaft): The expansion part is a key bar, which can be applied to items with heavy mechanical winding capacity.

3. Through-bar inflatable shaft (air-expansion shaft): The expansion part of the through-bar inflatable shaft (air-expansion shaft) is a through-length key bar, which has the characteristics of high precision, high load-bearing and light weight.

4. Slip inflatable shaft (air expansion shaft): Slip inflatable shaft (air expansion shaft) has been widely used in the slitting and winding of plastic films, metal foils, paper rolls, and PVC sheet coils.

What equipment is the inflatable shaft used on:

The expansion shaft has a wide range of uses, and all machines with winding, unwinding, and slitting can be applied to the inflatable shaft, even including the light metal industry. Such as printing industry: drying machine, flexo printing machine, gravure machine, trademark printing machine, etc.; Other machinery includes: waterproof membrane production line, various coating machines, leather machines, setting machines, embossing machines, slitting machines, die-cutting machines, rewinding machines, paper tube machines, bag making machines, laminating machines, laminating machines, film blowing machines, foam board production line machines, laminating machines, embossing machines, paper machines, non-woven machines, cloth inspection machines, hot stamping machines, battery film winding equipment and other related machinery supporting the use.

Precautions for purchasing inflatable shafts:

1. When customers choose an inflatable shaft, they need to consider many aspects, such as the use environment, working status, etc.;

2. If it is used for unwinding end, the total weight of the coil is not very heavy, you can choose the plate type inflatable shaft, if it is heavier, the key type inflatable shaft is more suitable;

3. For the winding end, if it is generally not very heavy, choose a plate inflatable shaft;

4. If the working environment will be in contact with corrosive objects, such as ozone sanitization, it is not recommended to use an inflatable shaft with rubber key strips; Stainless steel key bars and aluminum key bars can be used;

5. If it is installed on equipment like a round knife die-cutting machine, the cantilever inflatable shaft is selected, which can be rotated unilaterally, which is convenient for loading and unloading and improving efficiency.

PRE China factory can customize various sizes of inflatable shafts, from non-standard 18mm, to commonly used 3 inches, 6 inches, and larger 8 inches and 12 inches. Good technology, good quality, low price, fast delivery, after-sales stick. Welcome to consult PRE China factory.