Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Air shaft and mechanical shaft are two different transmission methods, each of which has its own advantages in different fields. A mechanical shaft, or shaft for short, is a type of part used for mechanical transmission. It is commonly used to carry mechanical components, transmit torque, start and stop mechanisms, and positioning. It can be said that the mechanical shaft is one of the indispensable and important parts in mechanical transmission, and its role is to transfer power from the motor or other prime mover equipment to the load.

The inflatable shaft is a special winding and unwinding shaft, that is, the shaft that can protrude on the surface after high-pressure inflation, and the shaft that quickly retracts the surface part after deflation is called an inflatable shaft. Its names are diversified, also known as pneumatic shaft, expansion shaft, flatulence shaft, inflatable roller, inflatable shaft, pressure shaft, inflatable roller, etc. This article will discuss the difference between air shaft and mechanical shaft from the aspects of structure, working principle, and application scenarios.

*Structural differences:

The structure of the air shaft is mainly composed of shaft core, air cushion medium, gasket, male and female connector and air path, as shown in the figure. When the compressed air is introduced, the air cushion medium of the air shaft expands, pushing the male and female heads to stretch outward, so that the air shaft clamps the material. When the material needs to be liberated, open the air release valve in the air hood, the air cushion medium of the air expansion shaft shrinks, and the male and female heads will be withdrawn according to the design, so as to achieve the purpose of unclamping the material.

The structure of the mechanical shaft is relatively complex, mainly composed of shaft core, shaft housing, cam, gear, keyway, key, etc. The working principle of the mechanical shaft is to use the cam and gear of the shaft core to drive the corresponding parts to rotate or travel, so as to realize the transfer or processing of materials.

* How it works:

The working principle of the air shaft is to use the expansion and contraction of the air cushion medium to achieve outward clamping or liberation of the material, which has the advantage of fast response speed and high clamp accuracy, especially suitable for the positioning and clamping of light and thin and vulnerable materials. At the same time, the air shaft can provide corresponding specifications of air cushion media for paper rolls of different diameters and materials, which has high flexibility.

The working principle of the mechanical shaft is to use the cam or gear tooth shape on the shaft core and the supporting mechanism to realize the transfer or processing of materials, which has the advantage of designing the corresponding parameters and materials for different needs, as well as having strong bearing capacity and adaptability.

*Application scenarios:

The air shaft is widely used in printing, packaging, cutting and other industries, and its core advantage is that it can quickly locate and clamp materials to meet the needs of high-speed printing, high-speed cutting and other industries. At the same time, the air shaft also has functions such as automatic positioning, manual positioning, and seamless connection, which is convenient for rapid conversion and adjustment in the production process.

Mechanical shafts are widely used in machinery manufacturing, transmission, processing and other fields, and their application range covers all walks of life such as heavy industry, light industry, and mining. The core advantages of mechanical shafts are strong bearing capacity, good adaptability, high stability, etc., and the corresponding parameters and materials can be designed for different needs, providing reliable guarantee for the transmission and processing of various materials.

*Class:

Types of mechanical shafts:

1. Ordinary shaft: Ordinary shaft is the most basic mechanical shaft, which is suitable for some simple mechanical transmission.

2. Precision shaft: Precision shaft is a precision machined mechanical shaft, which is generally used in mechanical transmission that requires high precision and high speed.

3. Telescopic shaft: Telescopic shaft is a kind of mechanical shaft that can adjust the length, which is mainly used in some mechanical transmissions that need to adjust the shaft length.

4. Elastic shaft: Elastic shaft is a kind of mechanical shaft that can absorb vibration and impact force, and is suitable for mechanical transmission that requires vibration and noise.

Types of air shafts:

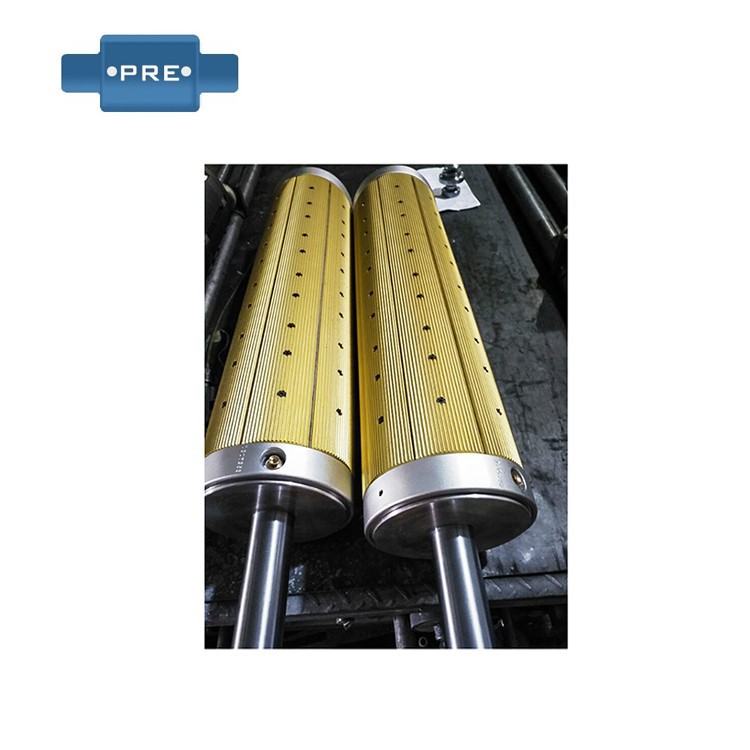

1. Slat-type inflatable shaft: The expansion part of the leaf type inflatable shaft (inflatable shaft) is a plate, which can be applied to machinery with high winding precision or lighter winding items.

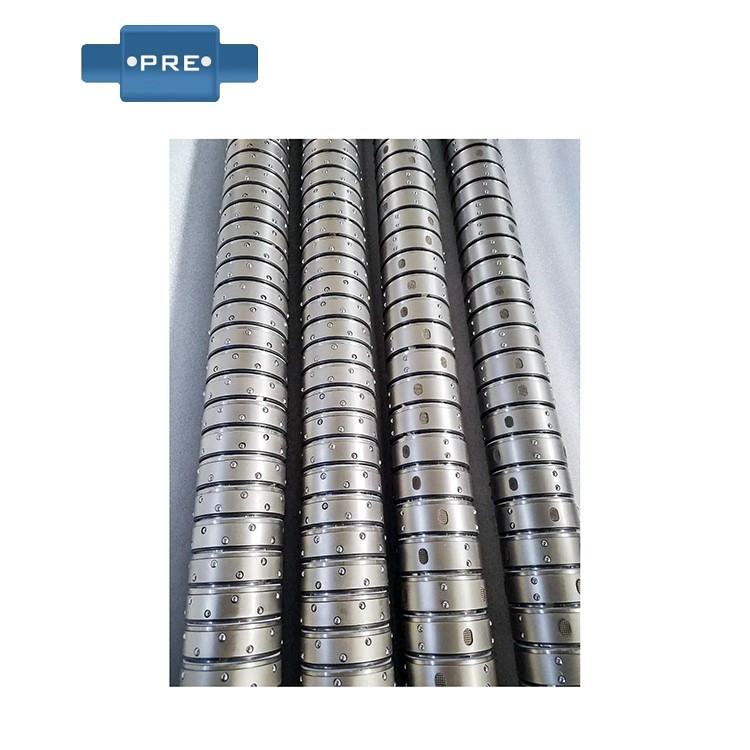

2. Keybar-type inflatable shaft: The expansion part of the lug type air expanding shaft (air-expansion shaft) is a keybar, which can be applied to items with heavy mechanical winding capacity.

3. Through-length key inflatable shaft: The expansion part of the multi bladder air expanded shaft (inflatable shaft) is a through-length key bar, which has the characteristics of high precision, high load-bearing and light weight.

4. Slip type inflatable shaft: Slip inflatable shaft (air shaft) has been widely used in plastic film, metal foil, paper roll; Slitting and winding of PVC sheet coils.

*Use:

The purpose of the mechanical shaft: The mechanical shaft is an indispensable part of the mechanical equipment, and its role is to transmit the power output of the motor to the load. Mechanical shafts have the functions of loading, transmitting torque and rotation, and have been widely used in many mechanical equipment. For example, manufacturing machinery, packaging machinery, processing machinery, transportation machinery, oil drilling rigs, etc.

The use of the air shaft: the air shaft has a wide range of uses: all machines with winding, unwinding and slitting can be applied to the air shaft. Suitable for printing equipment: drying machine, flexo printing machine, gravure machine, trademark printing machine and so on. It is suitable for other machinery and equipment: coating machine, leather machine, setting machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, rewinding machine, paper tube machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, cloth inspection machine, hot stamping machine, battery equipment and other related machinery and other related machinery.

Previous: When Is A Slat-type Inflatable Shaft Suitable?

Next: What Determines The Load-bearing Capacity Of An Air Inflatable Shaft?