Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

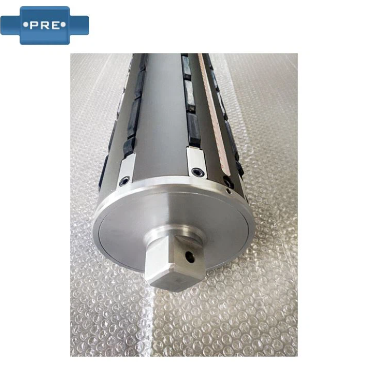

First of all, let's understand the manufacturing process and working principle of the pneumatic expander shafts:Production process:

1. Assemble, install and weld: the inner tube, the interference between the size and the outer tube is 0.4 mm, and the reverse welding angle of the two plates is 15X30 degrees. Polishing the inner tube, removing the slag, checking whether the size of the inner tube matches the inner diameter of the outer tube, and putting the hot sleeve in place. After cooling and shrinking, all these parts will be assembled and welded.

2. Annealing, rough turning, quenching: annealing heat treatment, inflatable shaft technology quenching and tempering, multiple stress elimination, rough turning allowance, static balance, more than 50 grams, demand accounting offset, borrowing lathe.

3. Dynamic balancing, electroplating and fine grinding: inflatable shaft. Do dynamic balance G40, block the ventilation hole, test the pressure without leakage, and do the hydraulic patency test. Electroplated hard chrome, fittings' unilateral 0.15 chrome layer is uniform, no pinholes and peeling.

4. Grinding and fine grinding mirror: It grinds the attachment with a disc grinder, and checks the attachment without water ripples, spirals, pinholes, flies and other spare parts.

5. Assembly welding: expansion shaft, welding inner plate, shaft head, bushing, baffle, inner tube, etc. The inner tube should be statically balanced within the range of 50 grams, and the inner tube should be rotated and scribed, and welded with a flat steel slideway.

6. The two-axle head is finely turned and rough-grinding and trimmed the pinhole, and the two-axle head is on the fitting. Its manufacturing process includes dynamic balancing, annealing, car matching, etc. It has a wide range of uses, and all machines with winding, unwinding, and slitting capabilities can be applied to inflatable shafts, even including the light metal industry.

Working principle: the use of the inflatable shaft is extremely convenient and fast, only need to provide its own air source, the air pressure is controlled in the range of 6-8kg/cm2, when the external parts (such as the round paper tube) need to be locked, as long as the air gun is inflated on the air valve on the inflatable shaft, it can be completed, and the external parts (such as the round paper tube) can be taken out when the paper needs to be relaxed.

In order to avoid the problem of air leakage, the most important thing is to pay attention to the following when installing and using the expandable shaft:

1. It is necessary to pay attention to ensure that the compressor that controls the air pressure is in a stable state, and install the filter directly on the compressor and the inflatable shaft to avoid impurities blocking the air pipe and causing air leakage;

2. The direction of the inflatable shaft of the air entering should be perpendicular to prevent damage to the valve;

3. When the inflatable shaft is exhausted, the standard exhaust port must be used, and it is forbidden to use sharp hammers and other tools to avoid air leakage;

4. It is to install pressure gauge and pressure control device, and the air pressure is controlled at 6-8kg/cm2;

5. It is a valve that is carefully placed to avoid hurting the inflatable shaft;

6. When replacing the air nozzle, please use the socket wrench, if there is a fault inside, when you need to disassemble, you can contact our professionals to install or disassemble.

In the process of using the inflatable shaft, how to check that the air expansion roller has leaked, there are the following 3 steps:

First of all, it is necessary to check the appearance of the inflatable shaft for obvious breakage or deformation. Since an inflatable shaft is a component that must be stable and durable, if there is a problem with the appearance of the inflatable shaft, it is likely to be caused by an air leak.

Secondly, it is necessary to check whether the inflatable shaft part produces abnormal noise. Because the operation of the inflatable shaft is essentially achieved by the expansion and contraction of gas, if the inflatable shaft leaks, it may produce abnormal sound or vibration.

Finally, there is a relatively simple way to check whether the inflatable shaft is leaking: use an air pressure gauge to measure the pressure of the gas inside the inflatable shaft. If the measurement results show that the gas pressure in the inflatable shaft is too low, then the inflatable shaft is leaking.

What should I pay attention to when repairing an pneumatic flat shaft?

The inflatable shaft is an important equipment widely used in the printing and packaging industry, which can process cylindrical objects and print them. During the use of inflatable shafts, it is inevitable that some problems will occur, and one of the common problems is the damage of inflatable shafts. At this time, it is particularly important to carry out inflatable shaft repairs. However, what do you need to pay attention to when repairing an inflatable shaft?

The main areas of application of inflatable shafts:

In the industrial field, inflatable shafts are widely used in all kinds of industrial machinery and equipment that require rewinding, unwinding, precise deviation correction, and automatic uniform slitting of coiled raw materials. Classification according to the properties or types of machinery used in inflatable shafts:

1. In the field of printing and packaging, there are: drying machine, flexo printing machine, gravure machine, trademark printing machine

2. Corrugated paper, metal, non-woven fabrics and other fields include: coating machine, leather machine, setting machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, cloth inspection machine, hot stamping machine, battery equipment and other related machinery supporting the use.