Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

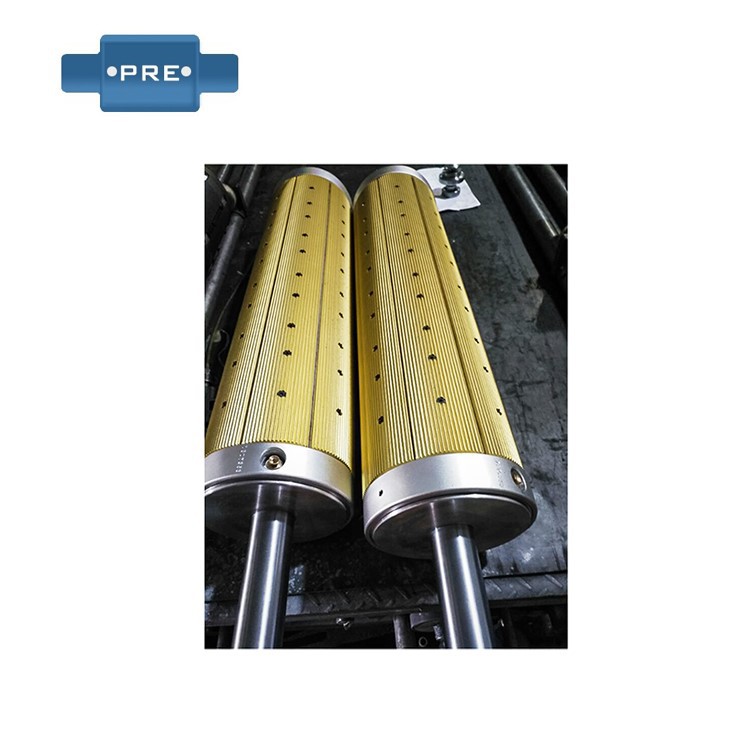

The expanded shaft is a special winding and unwinding shaft, that is, the shaft that can be inflated on the surface after high-pressure inflation, and the shaft that quickly retracts the surface part after deflation is called an inflatable shaft.

As long as the user provides his own air source, the air pressure is controlled in the range of 6-8 kg, when the reel core needs to be locked, as long as the inflation handle is inflated against the air valve on the inflatable shaft, it can be completed, and when the drum core needs to be relaxed, the sliding air core on the air valve can be deflated by hand.

How to replace an inflatable shaft airbag is a question that inflatable shaft users often ask from inflatable shaft manufacturers. Replacement of the airbag is also a necessary maintenance work, which can make the operation of the inflatable shaft more stable and prolong the service life.

Airbags are a key component in creating an inflatable effect, which is subjected to tremendous pressure and weight, so they can also wear and tear and damage due to prolonged use. When the airbag fails, the productivity of the inflatable shaft will be greatly affected, so it is very important to replace the airbag in time. This article will introduce the steps and precautions for replacing airbags for industrial inflatable shafts.

Common types of inflatable shaft airbags: Rubber Tubes for Air Shafts and transparent PU Bladder.

1)PRE Chinese factory transparent flat bladder:Suitable for multi bladder air shaft and differential air shaft. Transparent PU bladder is combined with R&D according to the sliding part of the slitting machine. It can repeatedly run at temperatures up to 80 °C, and the flat airbag can operate normally and keep it. Not deformed.

2)Rubber Bladder Suitable for air expanding shaft, gas drum, differential shaft, water rise, municipal pipeline repair, water trap, violent device, this bladder is developed according to the repairer and air shaft application, and can be inflated. Repeated inflation and deflation in the shaft for more than 100,000 times.

The general steps for replacing an bladder are as follows:

1) Lift the key on the pneumatic shaft body with screws;

2) Remove the valve and remove the screws on the shaft end of the valve;

3) Then use a hammer and an iron rod to knock out the shaft head;

4) Then take out your inflatable shaft airbag, where you can find the balloon that was broken, compare which position it is, what is the cause of the punctured balloon and air leakage, whether there is a spring to wear, if it is to put the entire shaft horizontally, put all the remaining leaf springs, it is necessary, and even check and install new spring blades in every link;

5) Install the old size airbag, replace the new size airbag, and press the two ends of the airbag with an impactor;

6) Install the airbag to one end of the shaft head, and then insert the entire airbag into the shaft head, and then screw it into the fix;

7) Install the gas nozzle, fill it, and check whether the gas nozzle is leaking. If not, remove all the screws on the shaft body, thus repairing an inflatable shaft.

Specific steps to remove the bladder:

1) Before disassembling the airbag of the inflatable shaft, you should first look at the structural diagram of the inflatable shaft before operating.

2) Press the steel head of the inflator nozzle first, drain the compressed air in the inflator shaft, and then remove the inflator nozzle.

3) Use a diameter of 1-1.2mm iron wire to penetrate the small hole on the key bar along the circumferential direction of the air expansion axis, and the same circumferential direction is a group; Tie all the keys tightly. Avoid when the airbag is pulled out. The key strip falls into the aluminum alloy roller, which can also facilitate the installation of the airbag.

4) And take out the set screws (M6 socket socket socket screws) and positioning sleeves that fix the two ends of the aluminum alloy roller and the air expansion shaft.

5) It is necessary to process a screw for the pin puller, and clamp the air shaft on the lathe.

6) Usually the contact surface between the inflatable end of the key strip air shaft and the aluminum alloy roller will be coated with sealant, you should use the gas welding gun first and heat it first, and then when heating, other parts should be cooled to avoid the deformation of the aluminum alloy roller.

7) Wait for the sealant to soften before pulling the end, because the airbag is connected to the inflatable end, and the airbag will be easily pulled out.

The causes of air leakage in the inflatable shaft, in addition to the problem of the airbag, there are other reasons, and the specific treatment measures are as follows:

1) Replace the inflator nozzle: If the inflator is leaking, simply replace the inflator nozzle again to solve the problem.

2) Tighten the compression ring: If the compression ring is loose, the solution is to tighten the compression ring.

3) Disassemble the shaft head and replace the hose: If the hose is broken, it will be more troublesome to deal with than other conditions, so it is necessary to disassemble the shaft head and replace the hose.

4) Check the airbag: If the internal airbag has been used for a long time and is aging and leaking, the airbag needs to be replaced.

5) Clean up the foreign body: If there is debris or sharp object that punctures the air bag, clean the foreign body first, and then replace the air bag.

The main precautions for avoiding air leakage in the use of inflatable shafts:

1) Make sure that the compressor that controls the air pressure is in a stable state, and install a filter between the compressor and the air shaft to avoid impurities clogging the air pipe and causing air leakage.

2) The direction of air entry should be perpendicular to prevent damage to the valve.

3) When exhausting, the standard exhaust port must be used, and it is forbidden to use sharp hammers and other tools to avoid air leakage.

4) Install pressure gauge and pressure control device to monitor the air pressure change, and control the air pressure in the range of 3-8kg/cm.

5) Handle with care so as not to hurt the valve.

6) When replacing the air nozzle, a socket wrench must be used. If there is an internal failure and it needs to be disassembled, you can contact a professional.

Areas of application for inflatable shafts:

The inflatable shaft is mainly suitable for printing equipment: drying machine, flexo printing machine, gravure machine, trademark printing machine, etc.; Other machinery includes: coating machine, leather machine, setting machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, cloth inspection machine, hot stamping machine, battery equipment and other related machinery supporting the use.

Previous: No Information

Next: No Information