Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

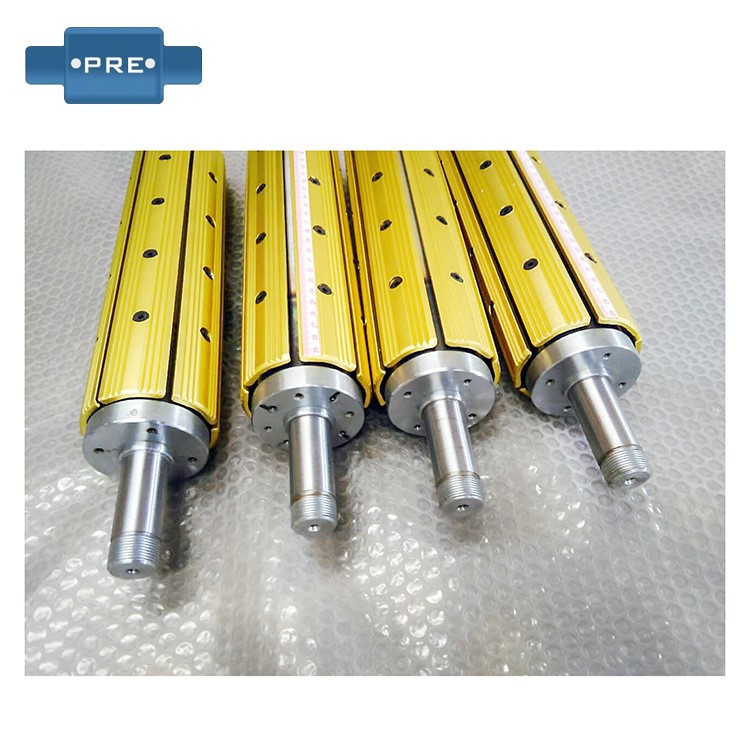

Pneumatic expanded shaft as an independently designed part, from 1 inch --- 12 inches, the length and size are determined by the actual needs of the customer, where there are slitting, printing, rewinding, coating, laminating, bag-making, papermaking and other work equipment or other related center coiling machinery, can be applied to the factory inflatable shaft. The inflatable shaft shaft body is designed for practical work, and it can be applied to various types of coiled pipes such as thickness, thinness, width and narrowness.

The operation time of the inflatable shaft is short, and the separation and placement of the coil can be completed with only 2 seconds of inflation and deflation action, and the placement of the coil is simple, convenient, safe and applicable. All machines and equipment for winding and unwinding can be applied to inflatable shafts. The length of the inflatable shaft can be up to six meters or more, and the shortest can be several hundred millimeters, all according to the customer's needs.

1) Working environment: Consider the working environment of the inflatable shaft, such as temperature, humidity, pressure and other parameters, as well as the weight and size that need to be bearing. Depending on the working environment, select the appropriate inflatable shaft material and specifications.

If the working environment will be exposed to corrosive objects, such as ozone sanitizing, it is not recommended to use an inflatable shaft with rubber key strips; Stainless steel key bars and aluminum key bars can be used;

2) The load-bearing capacity of the inflatable shaft: The load-bearing capacity of the inflatable shaft depends on factors such as its manufacturing materials, processes, and design. When selecting an inflatable shaft, it is necessary to choose an inflatable shaft with the right load capacity according to the actual needs to ensure that it can meet the work requirements.

The load-bearing capacity of the inflatable shaft is related to the type of inflatable shaft: if it is used for the unwinding end, the total weight of the coil is not very heavy, you can choose the plate inflatable shaft, if it is heavier, the key inflatable shaft is more suitable.

The load-bearing capacity of the inflatable shaft is related to the shaft tube material: the inflatable shaft is not the same because of different shaft tube materials, and in general, if you choose aluminum alloy as the inflatable shaft (inflatable shaft) shaft tube, then his bearing capacity is relatively poor, basically 300KG; If you choose steel as the inflatable shaft (air shaft) shaft tube, then it can bear more than one ton of weight, so our inflatable shaft (air shaft) enterprise users can choose their own materials according to the characteristics of the product during use.

3) Inflation and deflation speed: The inflation and deflation speed reflects the working efficiency of the inflatable shaft, and rapid inflation and deflation can make the inflatable shaft complete the expansion and contraction operation more quickly. Therefore, when choosing an inflatable shaft, it is necessary to consider whether the inflation and deflation speed meets the actual demand.

4) Dimensional stability: The dimensional stability of the inflatable shaft has an important impact on its working effect and service life. When selecting an inflatable shaft, it is important to understand its performance in terms of dimensional stability and consider whether additional machining or adjustment is required.

5) Ease of use: The ease of use of the inflatable shaft is also one of the factors to consider when choosing. The inflatable shaft is easy to install, operate and maintain, increasing productivity and reducing operating costs. Therefore, when choosing an inflatable shaft, it is necessary to consider its performance in terms of ease of use.

For example, if it is installed on equipment such as a round knife die-cutting machine, a cantilever inflatable shaft is selected, which can be rotated unilaterally to facilitate loading and unloading and improve efficiency.

6) Price: Price is one of the important factors to consider when choosing an inflatable shaft. When choosing, it is necessary to comprehensively consider the performance, brand and quality of the inflatable shaft, and choose the cost-effective inflatable shaft.

Advantages and disadvantages in working with an air expansion shaft:

The advantages of the inflatable shaft in the work mainly include:

1) Simple operation: The operation of the inflatable shaft is relatively simple, and the expansion and contraction of the shaft are realized by inflation and deflation, so as to conveniently complete the winding and unwinding work.

2) Wide applicability: the inflatable shaft can adapt to coils of different specifications, and can adapt to coils of different diameters by adjusting the air pressure, which improves the flexibility and versatility of the equipment.

3) Good stability: The inflatable shaft has good rigidity and stability in the inflated state, which can ensure the stability and accurate transmission of coil materials.

However, there are also some disadvantages of the air expandable shaft at work:

1) Need for air pressure system: The air shaft needs to be equipped with an air pressure system, which increases the complexity and cost of the equipment. At the same time, the stability and reliability of the air pressure system will also affect the working effect of the air shaft. 2)

2) Long adjustment time: When replacing coils of different specifications, the air pressure needs to be readjusted, which may take a certain amount of time, which affects the work efficiency.

3) Higher requirements for air pressure: the working effect of the inflatable shaft is greatly affected by the air pressure, if the air pressure is unstable or insufficient, it may lead to uneven expansion or contraction of the shaft, affecting the transmission effect of the coil.

Please note that these advantages and disadvantages will vary depending on the application, specific product design, and operation.

Expansion range of the inflatable shaft:

1) The expansion part of the plate inflatable shaft is the whole plate, the fulcrum is evenly dispersed, and the force is uniform, and the expansion height can reach 4mm to 5mm. For example, the diameter before expansion is 74mm to 75mm, and the diameter after expansion can reach 78mm to 80m.

2) Key inflatable shaft: the expansion part is the key bar, usually the unilateral expansion height can reach 5mm to 6mm, such as the diameter before expansion is 74mm to 75mm, and the diameter after expansion can reach 79mm to 81mm.

The range of pressures that can be withstood by the inflatable shaft:

The products produced by different inflatable shaft manufacturers, due to the relationship between the quality of the material, it will bear different pressures, the ordinary pressure is 300KG, if it is made of iron shaft material, then it can bear more than one ton of weight.

Inflatable shaft inflation and deflation process: inflatable shaft inflation self-supplied air source, air pressure controlled in the range of 6-8 kg.

1) When the reel core needs to be locked, it can be completed by inflating the inflatable handle against the air valve on the inflatable shaft.

2) When you need to loosen the drum core to discharge, press the sliding air core on the air nozzle by hand to deflate.

3) Simply put, it is the air valve used in the air pressure shaft in the deflation and inflation, it mainly plays the function of inflation and deflation, because the air pressure shaft often needs to be inflated or deflated in the working process, first of all, the inflatable handle should be aligned with the air nozzle on the air pressure shaft to inflat, and when deflating, it is necessary to slide the air core against the air pressure shaft nozzle to deflate, so that the key bar will return to the original appearance.

Therefore, there are many requirements for the air valve of the inflatable shaft, first of all, the sealing of the air valve should be good, which can ensure that the air valve can be filled and deflated within two seconds of the inflation shaft. And it is the internal air pressure guarantee, otherwise it cannot provide effective air pressure. The quality of the valve is good, most of the valve materials are made of copper as the basic material, because it is subjected to the pressure of 3-4 air pressures, so the pressure resistance is relatively high, and the production is more convenient.

Classification and application fields of inflatable shafts:

Air shafts are widely used in slitting machines, slitting machines, printing machines, blown film machines, bag making machines, coating machines, die-cutting machines and other equipment that needs to be used for rewinding and unwinding applications. The air shaft is divided into expansion key type inflatable shaft, plate type inflatable shaft, aluminum alloy inflatable shaft, air nail shaft, etc.

Customization of inflatable shafts:

Inflatable shafts are generally made according to the needs of practical applications, there are no standard parts, and different types are selected according to different actual needs. The common types are aluminum alloy inflatable shaft, expansion key inflatable shaft and vane inflatable shaft, etc., and some distinguish between metal and non-metal. The shaft body of the inflatable shaft is made of high-quality steel tube, the surface is chrome-plated, the aluminum convex key, flexible expansion and contraction, the high-quality rubber liner and the quick filling and exhaust nozzle, the sealing effect is good, the service life is long, and the detachable shaft head is easy to maintain.

In addition to the conventional inflatable shaft, the user can choose various types of products according to the actual needs and uses, the materials for selection are aluminum alloy or metal and non-metal, etc., our PRE China factory can also be attached according to the user's own design drawings and inflatable shaft weight and material and its accuracy requirements.

Previous: Comparison Of Key And Leaf Type Pneumatic Shafts And Their Process Of Replacing The Bladder

Next: Why Is The Air Expanded Shaft Lug Tip Inflated With Insufficient Inflationary Pressure?