Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Principle of the guide system:

The guiding sensor B emits infrared light/ultrasonic/laser/visible light to monitor the operation of the web and sends the signal to controller A. After the controller finds that the coil has position drift, according to the instruction preset by the controller, the correction frame C swings by the driver D, and the coil position is corrected. The automatic deviation correction system of the coil uses a photoelectric sensor to detect the position of the edge of the coil, and sends the measured position error signal to the controller, and after the control unit judges and processes, the drive motor is controlled to correct the coil with the deviation position to the correct position.

The FIFE guiding system offers several different inspection methods: edge detection, wire following or alignment. Its drive system is driven by low-speed synchronization, frequency conversion speed regulation, stepper and servo motors, and the drive stroke is strictly proportional to the coil offset. The system can also be used with different probes to meet the needs of detecting different coils, such as: infrared photoelectric, analog infrared photoelectric, etc. The microcomputer digital controller provides precise control of the various functions of the system.

Application of the web guiding system in the production process:

1) Deviation correction system (servo correction device) refers to the technical operation taken by the manufacturer to keep the side of the coil neat and consistent in the process of spraying, printing, punching, laminating, slitting or other coil winding. This is because if the edges of the web are not aligned, the subsequent steps can be wrong, resulting in wasted material or downtime for adjustments. Therefore, when processing the coiled material, it is necessary to carry out timely correction operation on the offset coil.

2) The deviation correction device is mainly used in the lateral deviation control of the web material, which can be used for all kinds of coils: such as web film, metal foil, non-woven fabrics, weaving and other coils on the long and fast production line, because of the speed, tensile force or uneven thickness of the material and various mechanical damage, resulting in the phenomenon of moving left and right and one-way deviation of the material on the production line, resulting in the processing action of the middle section is not easy to match, or the sending and receiving action of the front and rear sections is uneven, resulting in the loss of many materials and the difficulty of subsequent processing.

The structure of the correction system is as follows:

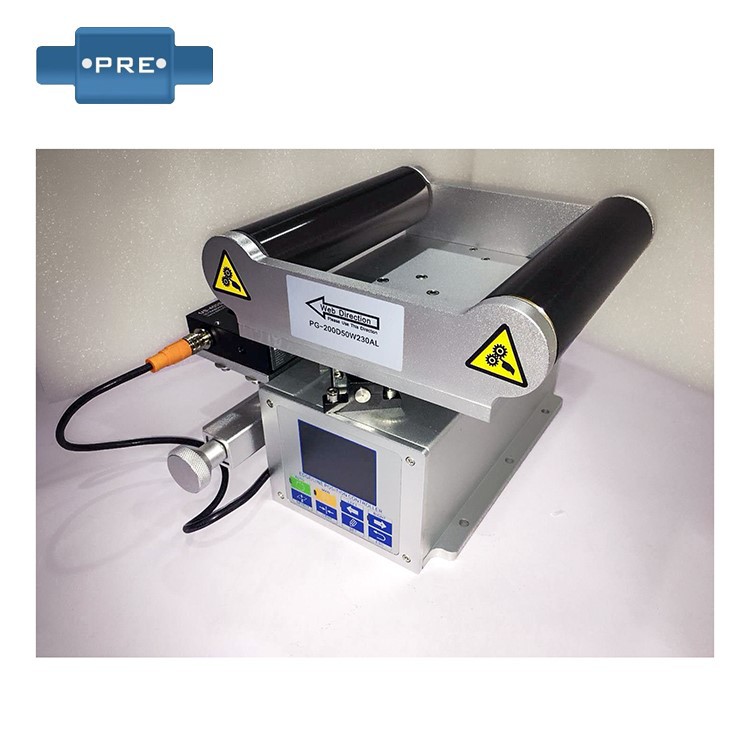

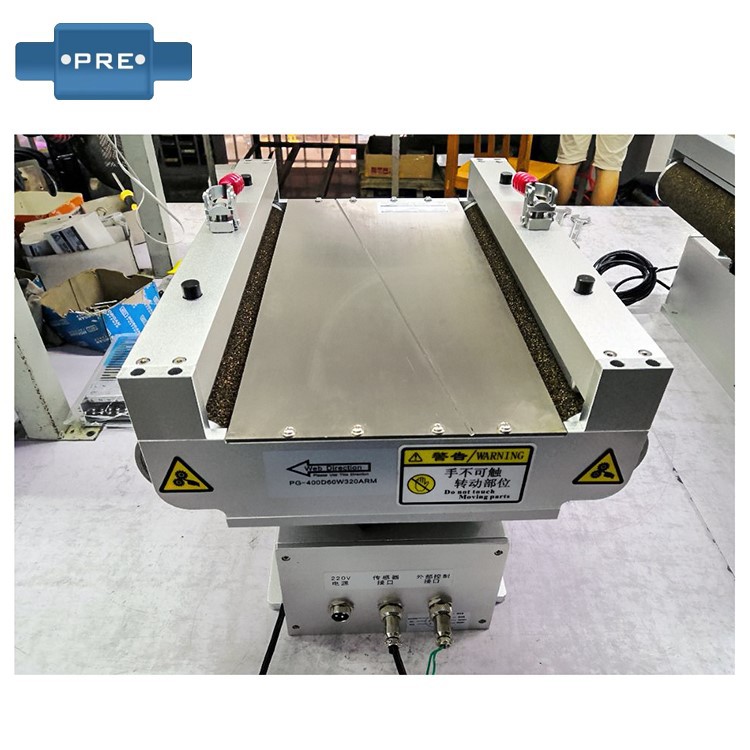

A typical guiding system consists of a guiding controller, a guiding sensor, a guiding frame and a driver.

What are the advantages of the web guiding system on the production line:

1) It can effectively improve the service life of the belt by 30% to 80%;

2) It can greatly improve work efficiency;

3) Save labor and minimize casualties;

4) Save energy and reduce energy consumption;

5) Avoid waste of resources caused by free and free materials.

Applications of the web guiding system:

Applicable industries: printing, packaging, papermaking, non-woven fabrics, lithium batteries, solar energy, rubber tires, textiles, metallurgy.

Applicable coil materials: web paper, film, metal foil, film, leather, non-woven fabrics, weaving and other coil materials.

Applicable equipment: printing and packaging, flexo printing machine, gravure printing machine, rotary printing machine, label printing machine, slitting machine, coating machine, laminating machine, inspection machine, die-cutting machine, film blowing machine, bag making machine, etc.

Non-woven fabrics: sanitary napkin equipment, sanitary pad production line, baby diaper production line, medical dressing production line, etc.

Lithium battery: electrode piece coating machine, pole piece rolling mill, slitting machine, winding machine, etc.

Rubber tires: extruders, cord production lines, calenders, cut-off machines, molding machines, etc.

About the accuracy of the photoelectric trainer

It is determined by three factors: the deviation of the incoming coil, the accuracy of the guiding system itself, and the installation accuracy of the photoelectric corrector. From the perspective of the optical guide supplier, the accuracy of the guiding system is defined as the position accuracy of the coil when it just comes out of the probe.

The adjustment method of deviation and jitter of the trainer is as follows:

1) Check whether the correction shelf is installed correctly.

2) Manually check if the actuator is only moving to one side, if so, the high power tube may need to be replaced.

3) If the actuator can move in both directions, but only deviates to one side after the electric eye is connected, it may be that the electric eye is damaged or the forward and negative directions of the control box are set incorrectly.

4) Check whether the corrector itself is in good condition, and after confirming that there is no damage, try to adjust the sensitivity of the correction servo. If it cannot be adjusted, it may be that the guiding system is faulty, the correct sensor type is not selected or the sensor is not calibrated, in which case the appropriate sensor model should be selected and calibrated.

5) If the corrector shakes, you can first check whether the coil tension is on, reduce the sensitivity, press Gain + (← or →) to adjust the gain, adjust the range (1-1050), adjust 125 times to light up a light, press and hold the button to adjust it all the time, reduce the motor drive speed, press Gain + Set+ (← or →) to adjust the speed of the drive, adjust the range.

6) If the corrector can only run to one side, first see if the correction shelf is installed correctly, if not for this reason, then adjust the position of the correction sensor, the power tube of the control box is damaged, check the method: use the manual way to see whether the actuator only goes to one side, if the manual only goes to one side, you need to replace the high-power tube. If you can walk on both sides manually, but only go to one side after the electric eye is connected, the electric eye is broken or the control box is in the wrong direction, replace the electric eye or adjust the control box.

Previous: What Is The Installation Distance Of The Guide System Related To?

Next: Common Breakdown And Treatment Of The Web Guiding System