Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The pneumatic expansionable shaft is a special winding and unwinding shaft, that is, the shaft that can protrude on the surface after high-pressure inflation, and the shaft that quickly retracts the surface part after deflation is called the inflatable shaft. Its names are diversified, also known as pneumatic shaft, expansion shaft, flatulence shaft, inflatable roller, inflatable shaft, pressure shaft, inflatable roller, etc.

The use of inflatable shaft and inflatable sleeve is very convenient and fast, only the user needs to provide their own air source, and the air pressure is controlled in the range of 6-8kg/cm2.

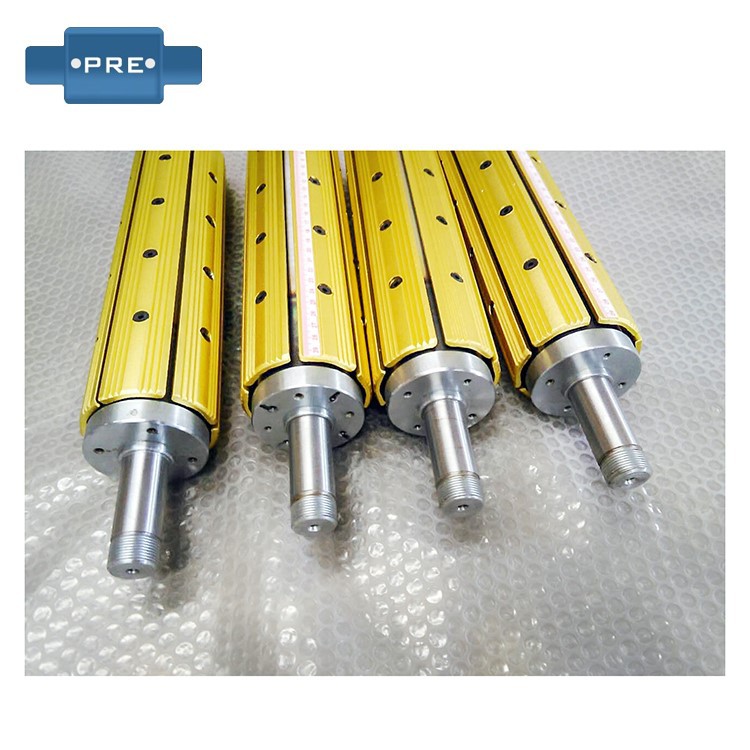

Description of the structure of the through-key air shaft:

1) Key bar material optional: rubber, aluminum or polyurethane. According to the special requirements of the user, other materials are optional.

2) The shaft material is divided into: aluminum alloy, natural/brown oxidation treatment; Steel.

3) Shaft head structure at both ends: customized processing according to the needs of different equipment, common flanges, optical shafts, key shafts, square heads, triangular heads, cone heads, internal tooth heads, etc., are produced according to the customer's drawings to meet any special requirements.

4) Types of inflatable air valves: divided into two types of structures, each size G1/4, G1/8, G1/16 specifications, each length has ordinary type, extended type.

5) Number distribution of inflatable nozzles: single nozzle/multi-nozzle can be selected, which are distributed in the outer circle of the shaft body/outer circle of the shaft head/the end face of the shaft head.

Characteristics of continuous lug air shaft:

1) The inflation operation time is short, and the separation and placement of the air shaft and the paper core can be completed in only 3 seconds, and there is no need to separate any parts on the end side of the shaft to tightly engage with the paper core.

2) Paper core placement is simple: with the action of inflation and deflation, the paper core can be moved and fixed in any position on the shaft surface.

3) Large bearing weight: according to the actual needs of customers, the size of the shaft diameter can be determined, and the use of high hard steel to increase the bearing weight.

4) Economical: The shaft is designed for special functions, and can be used for all kinds of thick, thin, wide and narrow paper tubes.

5) Simple maintenance and long service time: The inflatable shaft is a single part, and each part in its structure has a fixed specification, which can be interchangeable and convenient, making it easy to maintain.

6) The longest inflatable shaft can be six meters or more, and the shortest can be several hundred millimeters, all of which are determined according to customer needs.

Advantages of through-bar inflatable shaft:

1) The three-inch shaft is 5 separate airbags, and the six-inch shaft is 8 separate airbags, which is not easy to leak and simple to maintain;

2) The inflation area of the whole key bar is similar to that of the tile inflatable shaft, but there will be no inflatable part of the tile inflatable shaft that is easy to deform;

3) The key bar is a whole root, and the flatulence area is better than that of the key bar inflatable shaft;

4) The key bar is made of wear-resistant rubber, which is not easy to damage the paper tube and has a stronger grip;

5) The shaft body is made of high hardness alloy, which has high hardness and weight reduction of 30%-40% compared with ordinary materials, making it lighter to use.

6) Through-key inflatable shaft has a unique inflatable shaft design, the airbag and through-length key strip can be easily replaced without having to disassemble the shaft head.

Through-button air shaft use:

The use of air shaft is very wide, all machines with winding, unwinding, and slitting can be applied to air shafts, even including light metal industries.

For example, the inflatable shaft is mainly suitable for printing equipment: drying machine, flexo printing machine, gravure machine, trademark printing machine, etc.; other machinery includes: coating machine, leather machine, setting machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, cloth inspection machine, hot stamping machine, battery equipment and other related machinery supporting the use.

Precautions for installation and use of through-length key inflatable shaft:

1) When installing the inflatable shaft, the first thing to determine is that the compressor that controls the air pressure is in a stable state, and the filter is directly installed between the compressor and the inflatable shaft to prevent impurities from blocking the air pipe, thus causing the phenomenon of air leakage

2) The direction of air entry should be vertical to prevent damage to the valve

3) When exhausting, the standard exhaust port must be used, and it is forbidden to use sharp hammers and other tools to avoid air leakage

4) To install the pressure gauge and pressure control device, and the air pressure must be controlled in the range of 3-8kg/cm

5) When replacing the nozzle, you must use a socket wrench, if there is a failure inside, when you need to disassemble and repair, you should ask professional maintenance personnel, do not disassemble by yourself, so as not to cause unnecessary losses

6) Be careful not to hurt the valve.

To prevent air leakage failure of inflatable shaft, it is necessary to pay attention to:

1) When the inflatable shaft is installed, it is necessary to determine whether the compressor that controls the air pressure is in a stable state, and the filter is installed between the compressor and the inflatable shaft in the current stable state to prevent impurities from blocking the air pipe and causing air leakage faults;

2) The direction of air entry should be vertical to prevent damage to the valve;

3) When the inflatable shaft is exhausted, the standard exhaust port should be used, and it is strictly forbidden to use sharp hammers and other tools to avoid air leakage;

4) Install pressure gauge and pressure control device to monitor the change of air pressure, and control the air pressure in the range of 3-8kg/cm;

5) When replacing the air nozzle, a socket wrench must be used. When the inflatable shaft is faulty and needs to be disassembled and repaired, it is recommended to ask professional maintenance personnel and do not disassemble it by yourself to avoid unnecessary losses;

6) Be careful not to hurt the valve.

There are the following steps to find PRE China factory to customize the inflatable shaft:

1) The most direct way is to send the old inflatable shaft pictures or drawings to the PRE sales staff, and the PRE engineer will assist in the analysis.

2) If there is no drawing, the relevant parameters can be provided:

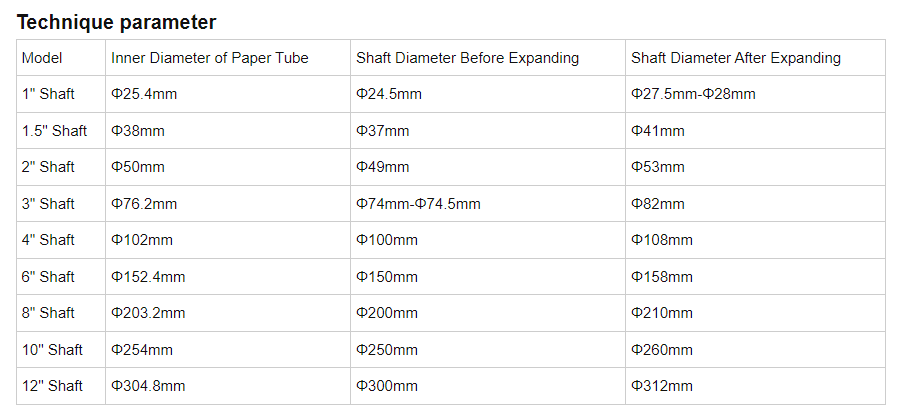

a. the diameter and length of the shaft body.Regarding the confirmation of the diameter of the shaft body, this also has a lot to do with the size of the paper tube of the material, such as the 3-inch inflatable shaft that we commonly use, the diameter before inflation is 74mm, which is suitable for about 76.2 paper tubes, and the diameter of the inflatable shaft is the best according to the inner diameter of the paper tube to leave 2-3mm margin, and the excessive margin may cause problems such as not tightening, shaking, and slipping.

b. the diameter and length of the shaft head.

c. the inner diameter of the paper tube.

d.the maximum width of the material.

e. the maximum bearing weight.

After analyzing the technical parameters, the PRE engineer will provide a preliminary drawing plan to the customer for approval.

3) Provide the order quantity, PRE salesman will provide a quotation.

Previous: Application Of Air Expanded Shaft On Laminating Machine

Next: Let's Take A Look At The Commonly Used 3''air Expanded Shaft