Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

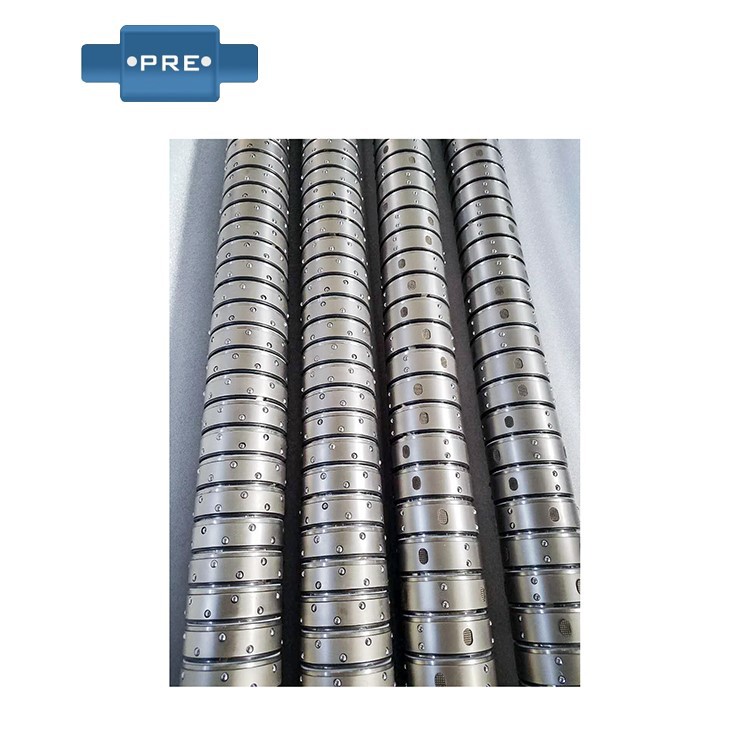

The air expanded shaft is a special winding and unwinding shaft, that is, the shaft that can protrude on the surface (referring to the key bar) after high-pressure inflation, and the shaft that quickly retracts the surface part (referring to the key bar) after deflation is called the inflatable shaft. Its names are diversified, also known as pneumatic shaft, expansion shaft, flatulence shaft, inflatable roller, inflatable shaft, pressure shaft, inflatable roller, etc.

Inflatable shaft specifications: There are many kinds of inflatable shafts, including 1 inch, 1.5 inch, 2 inch, 2.5 inch, 3 inch, 6 inch, 8 inch, 10 inch, 12 inch, etc., which can be processed and produced according to the needs of different specifications.

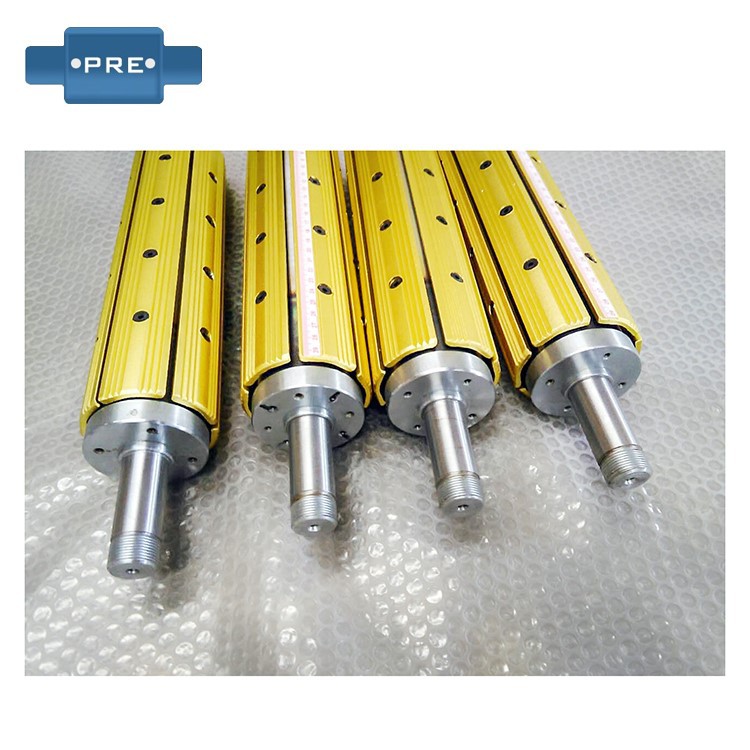

The Differential shaft, also known as the slip differential inflatable shaft, is a structure that sets the slip and torque independently of the special segments of the inflatable shaft, which can mainly solve the unwinding phenomenon caused by the thickness and uneven tension of each roll of materials, and can effectively improve product quality and production efficiency.

The differential shaft takes the precision hollow core ventilation spindle as the core, and uses compressed air to push the piston in the cavity, so that the shaft core generates friction torque between the friction parts and the differential slip ring, and further drives the oblique expansion plate on the inclined base to expand in the direction of the outer diameter, squeezes the winding cylinder, and transmits the torque of the winding cylinder, so as to achieve constant tension winding.

The differential slip shaft has a special structure, composed of a plurality of slip rings, when working, the differential slip rings are controlled to slip with a certain slip torque value (torque), and the amount of slip just compensates for the speed difference generated, so as to accurately control the tension of each roll of material, and to achieve constant tension winding, ensuring the quality of coiling. It can be applied to the range from very low to high tension, and is suitable for high speed, large material thickness error, multi-stage tension control, high tension control accuracy, and neat end face winding. Therefore, the inflatable unit of the differential slip shaft is composed of a cavity, an oblique base, a piston, an air seal, a bearing, a spring and an expansion plate, which plays a very important role. The fit between each fitting is also relatively important.

The connection between the birth of the inflatable axis and the slip axis:

The inflatable shaft is to fix the multi-roll winding barrel core on an inflatable shaft, and use a torque motor to drive the winding shaft or a combination of motor and magnetic particle clutch to drive the winding shaft, so that the linear speed of the data on the winding shaft is synchronized with the host to complete the multi-roll winding function. The advantage of this method is that the structure is complex, the cost is low, the unloading is convenient, and it is suitable for the data coiling with a small thickness error, less number of rolls and larger tension, and the data with a larger error about the thickness, more rolls and less tension is not suitable, and when it is serious, it cannot be coiled.

With the progress of people's living standards and the development of science and technology, higher and higher requirements are put forward for flexible packaging products, the elongation of the film is required to be smaller and smaller, the width of the winding end face is getting higher and higher, and the width is also required to be smaller and smaller, and some are even lower than 10mm, which puts forward higher requirements for the tension control of the film.

The tension control accuracy of the winding shaft directly determines the elongation of the slitting product and the degree of the end face, and the slip shaft is born. The advantage of the slip shaft is that it can deal with the results that the inflatable shaft can not handle, the width of the winding of the slip shaft can be very narrow, the tension is very huge, the precision of the winding is very high, and the flatness of the end face is very good, and these are the results that the inflatable shaft can not handle, and such a slip shaft can handle such results. The defect of the slip shaft is that the cost is too high, so if it is not a very high-end product, it is not necessary to use the slip shaft to stop the winding of the product under normal circumstances.

air expansionable shaft features:

The traditional inflatable shaft is controlled by an airbag The entire inflatable shaft, whether it is a plate inflatable shaft or a key inflatable shaft, there is only one round inflatable shaft, as long as there is an air leak, the whole inflatable shaft cannot be used normally;

With the improvement of our product requirements, our requirements for inflatable shafts are getting higher and higher, better than the traditional inflatable shaft accuracy is the new through-key inflatable shaft, the inflatable shaft is composed of several flat airbags, and the overall accuracy of the shaft is higher than the traditional inflatable shaft, which can meet the high requirements of a large part of customers.

The disadvantage of the inflatable shaft is that the whole shaft is of constant tension, and the tension cannot be adjusted, because the material that our users rewind will cause the tension of each rewinding material to be different due to uneven thickness, and the final result is that the winding material is not tight, the end face is not neat, and the raw materials are wasted at the same time.

Differential shaft features:

The slip shaft is mainly divided into two ways: central air pressure and side pressure, no matter which one, it has the function of slipping the slip ring, and the slip function is to wind multiple rolls of material on one shaft at the same time, because the thickness of the material is uneven, resulting in some coils being loose, some coils are tight, and the tight ones will be skidding, eliminating tension and achieving the ideal winding effect. The slip shaft adjusts the tension by adjusting the air pressure, so that the whole shaft is at a stable value.

When the material we rewind is too tight, the slip ring will slip with the axis to achieve an ideal tightness state, and this tension is related to the size of the air pressure, and finally it is manifested in the size of the tension.

Now the slitting machine has a set of air pressure system, the size of the air tension will continue to increase with the size of the roll diameter, because the larger the roll diameter, the greater the tension required for winding, so many users who do not have this system are manually adjusted, which requires the start-up master to have a good summary ability, and then adjust the size of the air pressure during the start-up process.

Advantages of through-bar inflatable shaft:

1) The three-inch shaft is 5 separate airbags, and the six-inch shaft is 8 separate airbags, which is not easy to leak and simple to maintain;

2) The inflation area of the whole key bar is similar to that of the tile inflatable shaft, but there will be no inflatable part of the tile inflatable shaft that is easy to deform;

3) The area of the key bar is better than that of the key bar type inflatable shaft;

4) The key bar is made of wear-resistant rubber, which is not easy to damage the paper tube and has a stronger grip;

5) The shaft body is made of high hardness alloy, which has high hardness and weight reduction of 30%-40% compared with ordinary materials, making it lighter to use.

Causes and solutions to the problem of air leakage of the airbag of the air expansion shaft:

1) Inflator leakage: Check the inflator nozzle, whether the inflator nozzle is normal. Strengthen the sealing of the contact surface between the inflatable nozzle and the inflatable end. The inflator nozzle is not normal, and the inflator should be replaced.

2) Air leakage in other parts: Check whether there is any damage to the surface of the airbag. If there is, you will need to replace the airbags. Third, it is to check whether there is a leak in the airbag and the inflatable end, and if there is a leak, the seal should be strengthened.

3) The key bar is disconnected: Check whether the combination of the key bar and the key bar guide seat is normal, and whether the base is damaged. Repair the base and secure the keyway to the base.