Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The function of aluminum guide roller sandblasting:

1) Remove surface pollutants and oxide layer: During the use of aluminum guide rollers, some dirt, oxides, etc. may accumulate on the surface, which will affect the surface quality and performance of the guide rollers. Sandblasting effectively removes these contaminants and oxide layers, cleans the surface of the guide rollers, and provides a basis for subsequent surface treatment and coating application.

2) Increase the surface roughness: The surface roughness of the aluminum guide roller has an important impact on the friction and adhesion with other parts. The right surface roughness can improve the coefficient of friction between the guide roller and other parts and the mechanical locking effect, thereby increasing the stability and reliability of the work. Sandblasting can increase the surface roughness of the guide roller to a certain extent and improve the friction effect with other parts.

3) Increase coating adhesion: If the aluminum guide roller needs to be coated and coated, sandblasting can increase the adhesion between the coating and the surface of the guide roller. After the sandblasting process, some tiny pits and lines will form on the surface of the guide roller, which can provide coating attachment points, so that the coating adheres more firmly to the surface of the guide roller, reducing the peeling and peeling of the coating.

Definition of Aluminum Guide Roller:

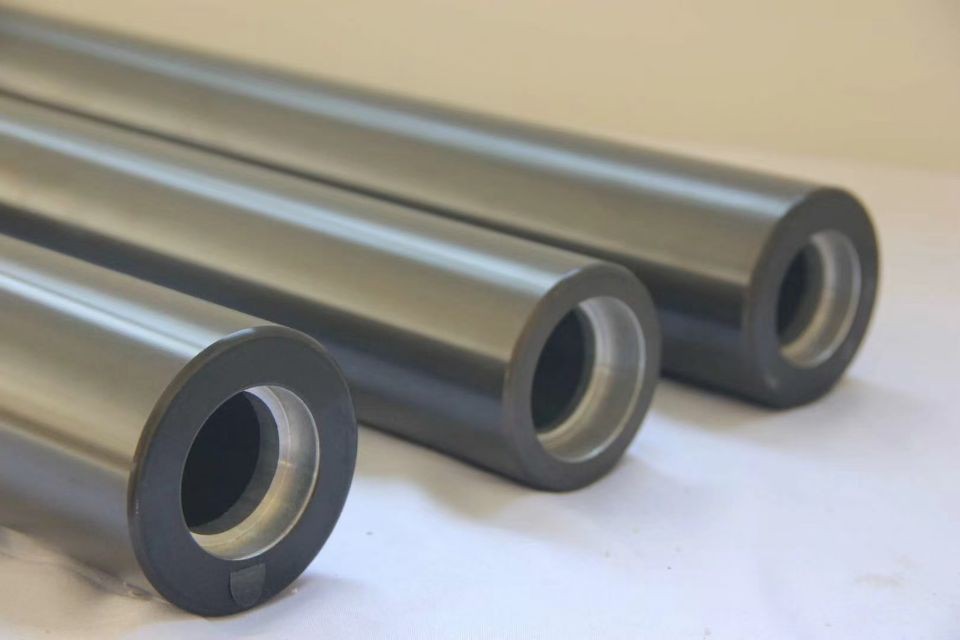

Aluminum guide roller, also known as aluminum alloy guide roller, is through the selection of better aluminum alloy material (6063-T5), through the mold into a tube type (from the outer diameter of 30mm~220mm) of various specifications, with a stiffener structure and high strength.

And the use of precision equipment and special tools for surface finishing, so that the surface is smooth, the coaxiality reaches 0.02mm, the whole axis is corrected by computer balance within 2g, the shaft end of the special process and with imported bearings, in high-speed operation, can run easily. According to the different needs of the industry, its surface can also be specially treated: sandblasting, anilox, Teflon and special hardening treatment HV700, so that it has good scratch resistance and wear resistance.

Aluminum guide rollers have high strength, low resistance, light weight, flexible rotation, no rust, wear resistance and corrosion resistance, especially suitable for printing, packaging, plastics, electronic batteries and other precision machinery industries and various coil processing industries.

Different surface processing methods of aluminum guide rollers:

1) Glossy: The aluminum guide roller has a smooth surface with low resistance, and can reach different surface roughness Ra0.3~Ra6.3 according to requirements

2) Surface thread line: Aluminum guide rollers commonly used are cross thread line and center expansion line (from the center to the two ends).

3) Concave and convex surfaces: various concave, convex and arc surfaces can be processed by CNC lathes.

4) Sandblasting or shot blasting: Sandblasting or shot blasting can obtain a rougher surface, which can increase friction.

5) Knurled or network cable: Aluminum guide rollers can be provided with different sizes of pattern surfaces according to customer requirements.

There are three major coating processes on the surface of aluminum guide rollers:

1) Electrophoretic coating

On the basis of anodizing, the aluminum guide roller is evenly covered with a layer of water-soluble acrylic paint film on the oxide film through the action of electrophoresis, so that the surface of the profile forms an anodized film and an acrylic paint film composite film. The feel is smooth and delicate, the appearance is bright and bright, in addition to the production of original oxidation coloring coloring on the basis of the color, can make more bright colors such as white and green.

2) Color powder coating

A total of more than 200 colors to choose from, giving designers a broad space, stable performance, strong adhesion of paint film, not easy to peel off, acid resistance, salt spray resistance, mortar resistance, weather resistance, aging resistance and other properties are very good. The coating is non-volatile, non-oxidizing, non-polluting and toxic in the air, and has good environmental performance. Surface dirt looks new after washing.

3) Color fluorocarbon spraying

The aluminum guide roller is sprayed with polyvinylidene fluoride paint coating on the surface of the aluminum alloy matrix through electrostatic action. Fluorocarbon coatings are vinylidene fluoride and fluorocarbon coatings. Therefore, it can have long-lasting color retention, anti-aging, anti-corrosion, anti-atmospheric pollution, and its fluorocarbon bond is one of the stronger molecular bonds, which is better than its polymerized molecular structure. Fluorocarbon spraying is used as a means of surface coating process. It has the advantage of uniform color and better resistance to fading and staining.

The influence of the surface treatment of aluminum guide roller on its performance is mainly as follows:

1) Abrasion resistance: Proper surface treatment can increase the surface hardness and wear resistance of aluminum guide rollers, and reduce the surface wear caused by friction. Common surface treatment methods such as oxidation, anodizing, etc., can form a layer of oxide film or coating with high hardness to improve the wear resistance of the guide roller.

2) Corrosion resistance: The surface treatment can improve the corrosion resistance of the aluminum guide roller, making it more resistant to the erosion of corrosive factors such as chemicals and moisture, and prolong the service life. Common surface treatments, such as anodizing, electroplating, etc., can form a protective oxide layer or plating layer to increase the corrosion resistance of aluminum guide rollers.

3) Surface smoothness: Surface treatment can improve the surface smoothness of the aluminum guide roller, reduce the frictional resistance, and improve the operation efficiency of the guide roller. Common surface treatment methods such as polishing and sandblasting can make the surface of the guide roller smoother and brighter.

4) Thermal conductivity: As an aluminum alloy product, aluminum guide roller itself has good thermal conductivity, and the surface treatment may affect its thermal conductivity. Some surface treatments such as anodizing may reduce the thermal conductivity of aluminum guide rollers, so the needs of thermal conductivity need to be considered when choosing surface treatments.

5) Aesthetics: Surface treatment can improve the appearance of the aluminum guide roller, increase its aesthetics and decoration, and make it more in line with the aesthetic requirements of the place of use.

Daily cleaning of aluminum guide rollers:

The cleaning of the aluminum guide roller after getting off work every day or after each batch of products is printed must be careful and clean, so as to avoid the oxidation of the surface layer of the rubber roller and the pigment and resin in the ink to form a smooth and hard film layer, or the vitrification of the rubber roller, which affects the transmission of ink.

Kerosene is generally used for cleaning, and then gasoline is used, because kerosene is not volatile, and gasoline is volatile, so that the cleaning can make the aluminum guide roller both clean and dry.

In general, the two ends of the aluminum guide roller of the offset printing machine are easy to accumulate ink, and the skin is dry and solid.

And don't rely entirely on the scraper when cleaning, use a clean cotton cloth to clean the places that the scraper can't clean, as well as the two ends of the aluminum guide roller.

Previous: Advantages Of Carbon Fiber Rollers

Next: What Are The Differences Between Different Materials Of Aluminum Rollers?