Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The principle of using the air expanded shaft is a special winding and unwinding shaft, that is, the shaft that can be expanded on the surface after high-pressure inflation, and the shaft that quickly retracts the surface part after deflation is called an inflatable shaft.

The airbag unloading of the air expansion shaft does not require the entire shaft to be removed. After directly deflating, the material can be taken away, because its width is not large, so it is more convenient to operate naturally. This is also the choice of many machines with light weight and small width.

The air-expansion shaft airbag has the effect of equalizing the force and pressure so that it can evenly distribute the pressure. It generally only takes about 2 seconds to complete the inflation and deflation process, and the steps to operate and place the coiled tube are very simple and practical, and it is not dangerous.

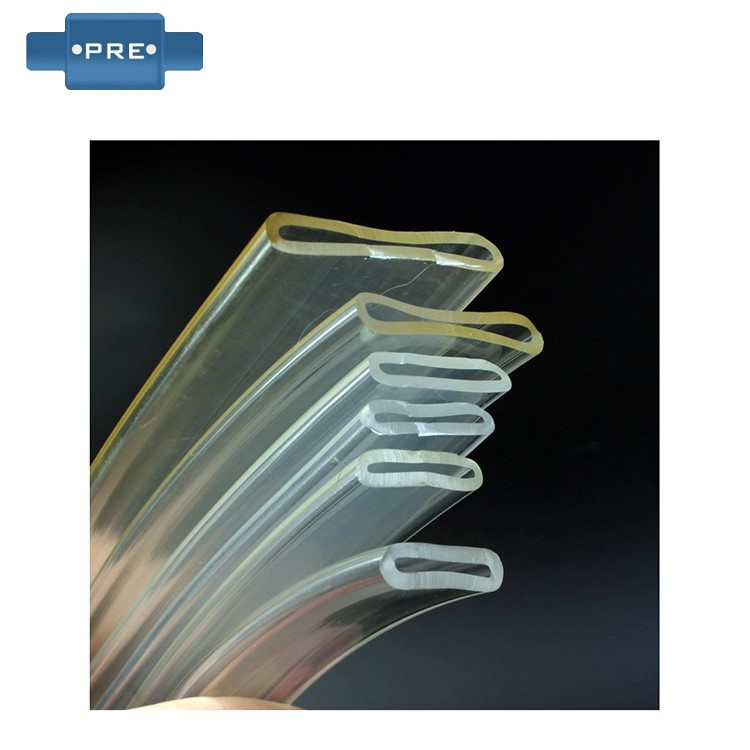

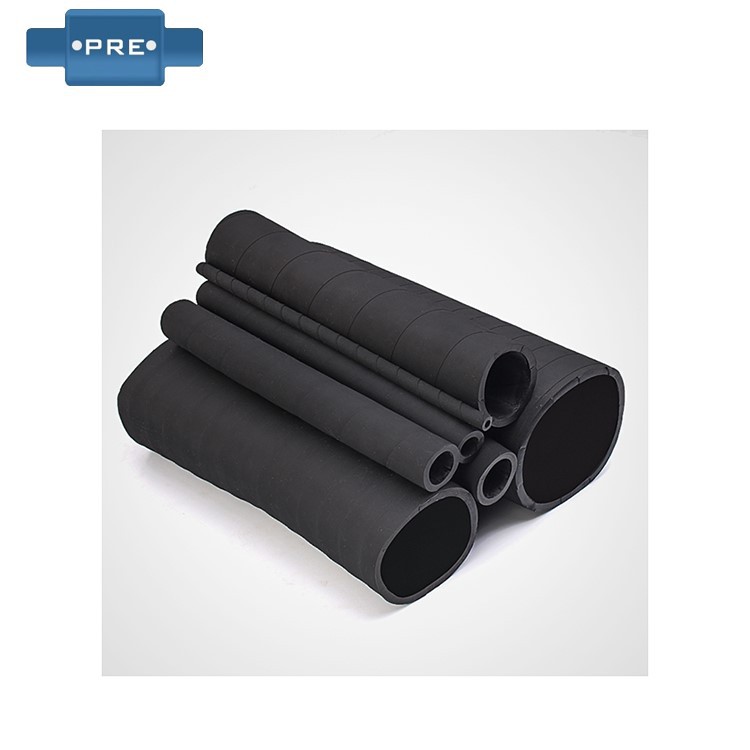

Inflatable axis airbags are divided into two shapes: round and flat, with round balloons generally being black and flat balloons generally clear/white.

Air expansion shaft airbag replacement method:

1) Hang the key on the shaft body of the air expansion shaft with screws;

2) Remove the air valve, and at the same time remove the screw on the shaft head at the end of the air valve;

3) Then use a hammer and an iron rod to knock out the shaft head;

4) Then take out the airbag shaft, you can find out where the airbag is broken, compare it to what position it is, what causes the puncture of the airbag and air leakage, whether there is a spring inside the piercing, if so, you must put the whole shaft vertically to get out all the remaining springs, it is necessary to even remove each key for re-inspection or even install new springs;

5) Install the size of the old airbag and replace it with a new one, and press the two ends of the airbag with an arresting machine;

6) Install the airbag into one end of the shaft head, then stuff the whole airbag into it, and then screw the shaft head into it;

7) Install the air valve, inflate and then check whether the air valve is leaking, if not, remove all the screws on the shaft body, and a flat-filled shaft will be repaired in this way.

specific classification of inflatable shafts:

1) Slatted inflatable shaft is suitable for slitting, printing, rewinding, coating, laminating and other mechanical cooperation that requires high true circle or surface winding. Available for slitting and cantilever single-shaft unwinding, the six-piece design allows for more balanced support and longer life for the protective airbag.

2) The key bar inflatable shaft is suitable for slitting, printing, rewinding, coating, laminating and other mechanical cooperation that requires a high circle or surface winding. Designed for shaft winding and single-shaft unwinding to meet the customer's needs for high tension or torque, as well as to withstand high material weights.

3) Through-strip inflatable shaft, rewinding and unwinding can be applied, multi-airbag design, the length of the airbag is similar to the main body of the inflatable shaft. The main body material can be steel or aluminum; The key bar is available in rubber, aluminium or polyurethane. According to the special requirements of the user, other materials are optional.

4) Mechanical inflatable shaft is mainly used in occasions where dynamic balance is required; It can be adapted to high-speed applications; The product has the performance of high concentricity as a whole, and has good control over the runout of the rotation of the coil; It also has excellent performance in situations where precise positioning is required.

5) The carbon fiber inflatable shaft is only 1/4 of the weight of the traditional inflatable shaft, which is very suitable for high load and manpower handling and loading and unloading. It can reduce the occupational injuries of operators in handling, improve work efficiency, and have the best ergonomic advantages and excellent performance. The optimized internal structure design represents the future of the inflatable shaft industry, and there is no violent vibration even at high speeds. The cross-sectional modulus with the optimal ratio of strength is widely applicable to various application requirements; Special surface treatments can be applied in a variety of special environments (dust-free, corrosive, high-temperature environments).

When the key inflatable shaft is leaking, you need to operate the following steps:

*Disassemble the key inflatable shaft first:

1. Before disassembly, take a look at the structural diagram of the key inflatable shaft, and then operate it manually. First, press the steel head of the inflatable shaft inflation nozzle to expel the compressed air in the inflatable shaft, and then remove the inflation nozzle. Use a wire with a diameter of 1-1.2 mm through the small holes in the key belt along the circumferential direction of the inflatable shaft to make a set of small holes in the same circumferential direction, and tie all the key strips firmly. Prevents the airbag from being pulled out. The health strip falls into the aluminum alloy roller, and the airbag is easy to install. Remove the set screws (M6 hexagonal concave head screws) and positioning sleeves that hold the aluminum alloy rollers and both ends of the inflatable shaft.

2. The screws of the pin puller need to be machined, and the inflatable shaft is clamped on the lathe. In general, the contact surface between the expansion end like a keyed inflatable shaft and the aluminum alloy rollers will be coated with sealant. You should heat it up with a gas welding gun first. When heated again, the rest should be cooled to prevent the aluminum alloy rollers from deforming. Once the sealant has softened, pull out the ends. Since the airbag is attached to the inflatable end, the airbag can be easily pulled out.

3. Then check whether the inflatable shaft inflator nozzle is leaking: Check whether the inflatable nozzle is normal. Strengthen the sealing of the contact surface between the inflatable nozzle and the inflatable end. If the inflator is abnormal, the inflator should be replaced. or inflatable shaft, the rest of the air leaks: Check the surface of the airbag for damage, if so, the airbag needs to be replaced. Also, check the airbag and the inflatable end for air leaks. If there is an air leak, strengthen the seal. Another possibility is the disassembly of the key bar of the inflatable shaft: check whether the connection between the key bar and the guide seat of the key bar is normal, and whether the base is damaged. Repair the base and secure the key strip to the base.

* Assembling key inflatable shaft:

1. Apply special glass glue to the airbag connector at the inflatable end, and place the airbag on the airbag connector. The airbag is then tied to the joint with a wire with a diameter of 1-1.5 mm. Connect (take care that the bundle should be firm to prevent air leakage). The balloon clamping sleeve is placed on the end of the airbag and a special foam is applied to the inflatable head. causes the head to inflate into the air sac. Let the capsule sit for a while and wait for the glass gel to set. Install the inflatable nozzle to the inflatable end.

2. Using an inflator, align the inflator nozzle and fill the airbag with compressed air. Please note that the airbag is not limited by external pressure at this time, and the inflation should not be excessive; Prevent damage to airbags. Put the inflatable end and the airbag together in the aqueous phase and observe whether the inflator and the airbag leak.

3. The key inflatable shaft can be assembled after the inflatable nozzle and airbag are sealed properly. Apply anaerobic glue on the contact surface of the fixed end and the aluminum alloy roller, and then align the fixed end with the positioning hole of the aluminum alloy roller. At the junction between the fixed and expanded ends and the aluminium alloy rollform, there are steel grades. Be careful not to install the ends incorrectly, and then press the fixed ends into the aluminum alloy rollform. Install the locating sleeve, tighten the locating screws, and tighten the countersunk hexagonal concave screws.

4. After the contact surface between the inflatable end and the aluminum alloy guide roller is coated with anaerobic soft rubber, it is installed in the aluminum alloy roller type together with the airbag, the positioning sleeve and the positioning screw are installed, and the countersunk hexagonal concave screw is tightened. Remove the wire from the key strap. Inflatable and deflate the inflatable shaft to ensure that the healthy bar can float up and down. The inflatable shaft is then placed into the core hole of the roll paper and filled with compressed air. After being placed for a period of time, if there are no missing keys or dropped keys on the key inflatable shaft, it can be used normally.

How to buy inflatable shaft bladder from Chinese supplier-PRE:

1) For round tube balloons, ID*OD*wall thickness is required.

2) For flat airbags, height/width *wall thickness is required.

Previous: What To Pay Attention To When Drawing An Air Expanded Shaft

Next: Talking About The Carrying Weight Of The Air Expanded Shaft