Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

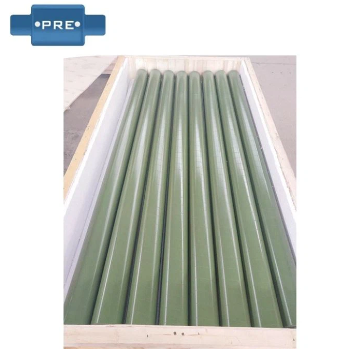

Aluminum rollers, also known as aluminum alloy guide rollers, are made of excellent aluminum alloy materials. It is suitable for printing, packaging, plastic, and electronic battery molding into tubes of various specifications (outer diameter 30mm-220mm). It has a reinforced ribbed structure and high strength. The surface is finished using precision equipment and special tools to make the surface smooth and the concentricity reaches 0.02 mm.

The whole shaft can be easily run at high speed, the shaft end and imported bearing adopt special technology, and the computer balance correction is within 2g. Depending on the requirements of the industry, its surface can also be treated with special treatments: sandblasting, anilox, Teflon and special hardening treatments, which make it have good scratch resistance and abrasion resistance.

Aluminum alloy guide rollers have the advantages of high strength, low resistance, light weight, flexible rotation, no rust, wear resistance, corrosion resistance, etc., especially suitable for printing, packaging, plastics, electronic batteries and other precision machinery industries and various coil processing industries.

Aluminum guide rollers are usually made of aluminum alloy material, which is lightweight, strong, and corrosion-resistant. Common aluminum alloy materials include 6061 aluminum alloy and 6082 aluminum alloy, which have good mechanical properties and processing properties, and are suitable for manufacturing guide rollers, which need to withstand certain pressure and wear. The choice of manufacturing materials for aluminum guide rollers will also vary according to the specific use environment and requirements to ensure that they can meet the corresponding job requirements.

Structure of aluminum guide rollers:

From the point of view of the surface structure of the aluminum guide roller, it is mainly composed of mesh holes and mesh walls. From the perspective of composition and structure, it is mainly composed of roller core, substrate and surface coating. The commonly used material for the base layer is electroplated copper, which is the basis for making mesh holes and mesh walls; The surface coating is made of metallic chromium or ceramic, which mainly improves wear resistance and blocks the corrosion of the substrate copper layer by solvents.

Compared with other material guide rollers, aluminum guide rollers mainly have the following advantages:

1) Light weight and high strength: Aluminum guide rollers have high strength and hardness, and at the same time, they are light in weight, which is conducive to reducing equipment load and saving energy costs.

2) Good thermal conductivity: Aluminum guide rollers have good thermal conductivity, which can quickly dissipate heat and avoid excessive heat generated by friction, which helps to prolong the service life of the equipment.

3) Good corrosion resistance: The surface of the aluminum guide roller has been specially treated (such as oxidation treatment, coating, etc.) to improve its corrosion resistance, and it is suitable for industrial occasions in humid and corrosive environments.

4) Excellent manufacturing process: The manufacturing process of aluminum guide rollers is mature, which can achieve precision machining and good surface treatment to ensure quality and stability.

5) Cost-effective: Compared with some materials, the production cost of aluminum guide rollers is relatively low.

6) Recyclable: Aluminum guide rollers can be recycled and reused, which is in line with the concept of environmental protection.

Compared with other material guide rollers, the flexibility of aluminum guide rollers is mainly reflected in the following aspects:

1) Material characteristics: Aluminum is a lightweight metal with high strength and flexibility. Compared to other materials, such as steel or iron, aluminum has good bendability and elasticity, making aluminum guide rollers flexible.

2) Structural design: Aluminum guide rollers are usually designed with a hollow or grid-like structure to keep the weight low and provide good natural deflection and flexural capacity. This design allows the aluminium guide rollers to be well adapted to a wide range of deformations and forces in the application.

3) Surface treatment: Proper surface treatment of aluminum guide rollers, such as anodizing treatment, can increase their surface hardness and wear resistance, while maintaining a certain flexibility and elasticity. This treatment can increase the flexibility of the aluminum guide rollers and increase their service life.

4) Thermal conductivity: Aluminum has high thermal conductivity, which can transfer thermal conductivity from the roller body to the surface of the material faster. This conductivity allows the aluminum guide roller to adapt well to the temperature change of the roll surface, reducing the deformation of the material or roll surface caused by the temperature change.

Compared with other material guide rollers, aluminum guide rollers have scratch resistance and wear resistance mainly because of the following reasons:

Through the mold into a tube type (from the outer diameter of 30mm~220mm) of various specifications, there is a stiffener structure inside, high strength. And the use of precision equipment and special tools for surface finishing, so that the surface is smooth, the coaxiality reaches 0.02mm, the whole axis is corrected by computer balance within 2g, the shaft end of the special process and with imported bearings, in high-speed operation, can run easily.

According to the different needs of the industry, its surface can also be specially treated: sandblasting, anilox, Teflon and special hardening treatment HV700, so that it has good scratch resistance and wear resistance.

The main factors affecting the price of aluminum guide rollers:

1) Size and specification: The size and specification of the guide roller have a direct impact on the price. Larger size guide rollers often require more material and machining techniques, resulting in higher prices.

2) Material selection: Different aluminum alloy materials have different costs. Aluminum alloys with characteristics such as high strength, high wear resistance, and high corrosion resistance are usually more expensive.

3) Processing technology and surface treatment: Special processing technology and surface treatment (such as oxidation treatment, spraying, chrome plating, etc.) will increase the production cost, which in turn will affect the price of the guide roller.

4) Customization requirements: If the guide roller has special customization requirements, such as special shape, precision requirements, installation methods, etc., additional processes and materials may be required, resulting in an increase in price.

5) Production batch: Normally, a larger production batch can reduce the production cost, because it can improve the raw material procurement benefit and process efficiency. As a result, high-volume orders may be priced more competitively.

6) Supply and demand relationship between demand and market: market demand and the resources and production capacity of suppliers will also affect the price of guide rollers. If demand is greater than supply, or if supplier resources are limited, prices may rise.

Precautions for the maintenance of aluminum guide rollers:

1) Correctly adjust and regularly check the pressure between the ink rollers of the printing machine;

2) The rubber printing roller with a bright surface cannot print a good product;

3) The dry ink accumulated on both sides of the ink roller of the printing machine should be removed regularly;

4) The ink skin stuck to the nylon (plastic) roller should be cleaned regularly;

5) Strictly check the diameter of the swinging ink roller;

6) The diameter of the ink roller is worn small, which will affect the ink supply capacity.

7) Do not use benzene (Tianna water) to clean the ink roller of the printing press unless necessary;

8) Appropriately set the amplitude of the ink roller of the swinging printing machine, and the amplitude should not be too large.

9) Regularly disassemble the ink channel steel sheet to remove the ink accumulation; Otherwise, it will affect the poor ink drainage.

10) Every month, the surface of all printing rollers should be treated with ink roller cleaning paste to remove the clean and hardened ink film.

11) When cleaning the ink roller of the printing machine, the pressure of the ink scraper should not be too large.

12) Cracks or pits on the printing roller must be a precursor to excessive pressure or poor adjustment.

13) The printing roller bearing should be oiled frequently.

14) Don't let the printing roller run at high speed for a long time without any protection.

Previous: How To Achieve Scratch Resistance, Anti-sticking And Firmness Of Aluminum Rollers?

Next: What Are The Performance Advantages Of Carbon Fiber Guide Rollers On Lithium Battery Winders