Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Carbon fiber rollers are mainly used in printing, textile and other industries, including transmission shafts of transmission equipment, etc., and even have a tendency to replace metal rollers

Low, the rigidity is also insufficient. The hardness of steel material is low, especially easy to cause surface damage, including if it is a relatively large width paper machine, and if metal rollers are used, then the whole is heavy, and it is easy to cause deformation, and the quality of the paper produced after operation will deteriorate.

At this time, it can be improved by increasing the thickness of the load-bearing deformation, but the greater the weight, the greater the inertia in operation, the higher the load, the fatigue resistance of the roller, and the greater the difficulty in maintenance and equipment parts replacement. Carbon

The paper machine after the fiber roller has been well compensated for in these missing places above, although it cannot be said to completely solve the above problems, but it is much better than the metal roller.

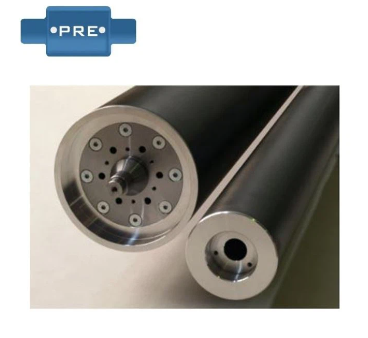

The carbon fiber brocade is produced and processed from the carbon fiber tube, mainly carbon fiber material, the performance characteristics of carbon fiber material is light weight and high strength, which makes the quality of carbon fiber roller very light, which solves the defect that the original roller quality is too heavy, and the effect is also very good

At the same time, it can reduce the weight, but also make the strength of the current roller shaft far exceed that of the metal roller, including reducing the weight of the lifting shaft, and the load requirements for the commission parts of the equipment are also lower, which greatly improves the service life of the equipment. In addition, the lighter carbon fiber rollers are also easier and more convenient to use

The degree is very high, and the production efficiency has also been greatly improved. Therefore, the combination will reduce the cost of carbon fiber rollers.

The dynamic balance effect of carbon fiber roller is better than that of metal roller, which can better have a good running effect for carbon fiber roller in the application, to ensure that after paper production, the quality is more guaranteed, and under high-intensity operation, it can still have a very good running effect Carbon fiber roller also has a very strong effect

Under the same product structure, the deformation of the carbon fiber roller with lower quality is also smaller, and the effect will be better, even in large-scale paper production, it can also ensure that the roller is not bent and deformed, and it will not rotate and jump at the speed of the pickaxe in use.

Compared with a lot of metal lifts, the surface of the carbon fiber roller has very good corrosion resistance, which can greatly improve the service life of the carbon fiber roller. Including the production and processing performance of carbon fiber rollers, it can be processed and produced very well according to the corresponding size.

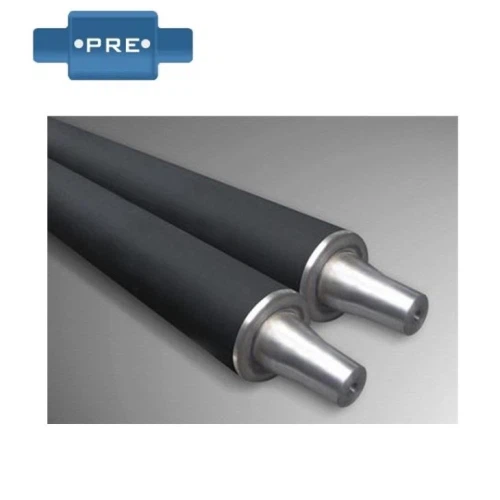

Main advantages: Compared with the traditional metal drive shaft, it has the characteristics of light weight, high efficiency, low vibration, low noise, easy maintenance and energy saving.

1) It is more rigid and less deflective than traditional steel and aluminum rollers (it can carry strong torque and tension at high speeds).

2) It is lighter than traditional steel and aluminum rollers, and the specific gravity is only 23% of steel.

3) It is more wear-resistant than the traditional steel and aluminum roller surface. Increase the service life of the rolls and reduce machine maintenance.

4) Light weight, high elastic modulus, can reduce the diameter and moment of inertia of the roller, increase the range of high-speed stable rotation speed, and can increase the limited speed of the roller body, more than double the speed of the steel roller.

5) The uniformity of the roller body made of uniform carbon fiber filament winding and carbon fiber cloth coating is higher than that of the traditional roller piece. It is calibrated by a precision dynamic balancer, and the runout of the roller body is within 0.03mm when the speed reaches 1200rpm.

6) Compared with the traditional roller parts, the inertia is relatively small in the process of high-speed operation, and the torque is reduced by an average of 50% compared with the steel core.

7) Carbon fiber guide roller conduction also has the effect of removing static electricity.

8) The carbon fiber guide roller itself is corrosion-resistant, which is suitable for chemical corrosion occasions.

9) The carbon fiber guide roller is not sensitive to temperature, the expansion coefficient is 0.2x10-6/°C, and its own change can be ignored under the change of ambient temperature, which makes the equipment more stable.

Application of carbon fiber guide roller in rewinder:

With the rapid development of papermaking technology, the speed of the paper machine is getting faster and faster, the width of the paper is getting faster and faster, and the paper machine is large-scale and high-speed, which has higher and higher requirements for the equipment, and the guide roller is a major factor in improving the speed of the paper machine.

Conventional guide rollers are metal guide rollers, generally steel and aluminum materials, because the characteristics of these materials Bunsen, length, speed to reach a certain value, has reached the limit, so the use of carbon fiber composite materials, can further improve the speed and width of the paper machine.

Carbon fiber (CF) is a brittle material with a carbon content of more than 90% converted by organic fibers through a series of heat treatments, carbon fiber is black, with high strength, light weight, high temperature resistance, burning resistance, corrosion resistance, radiation resistance and other characteristics, is a new material with excellent mechanical properties,

His specific gravity is less than 1/4 of the rigid, the tensile strength is 7-9 times that of steel, and the tensile elastic modulus is also higher than that of steel, so it can be used instead of steel, and the weight is greatly reduced without weakening the strength;

Before the carbon fiber composite guide roller is manufactured, it is analyzed by finite element design software to determine the appropriate winding angle and thickness, and all parameters are checked to meet the design requirements.

Application advantages of carbon fiber composite guide rollers in the paper industry:

1) Improve the quality of the paper web: improve the consistency of the CD of the paper web and reduce the rump

The bending deformation of the steel roller will cause the uneven direction of the paper web CD, especially after a long time of shutdown and start-up, it takes a long time of operation to ensure the uniformity of payment, and the carbon fiber composite guide roller is smaller than the steel roller deformation, which reduces the training time after the shutdown starts and the unqualified products with poor CD profile after start-up.

2) Improve the stability of the paper machine

The carbon fiber composite guide roller of the same specification is much lighter than the steel roller, and the unbalance of the dynamic balance can be very small, which greatly improves the stability of the guide roller operation and reduces vibration.

3) Increase the speed of the vehicle

The stability of the carbon fiber guide roller and the decrease of the load bring more space for the smooth speed-up, which can quickly increase and reduce the speed.

4) Energy saving and consumption reduction

The lightweight carbon fiber composite guide roller has lower rotational inertia, and the motor selection and load are greatly reduced

5) Reduce equipment maintenance

The lightweight carbon fiber composite guide roller has only 1/5 of the quality of the steel guide roller of the same specification, which prolongs the service life of the bearing.

Application of carbon fiber rollers on coaters and laminators:

Coating machine and laminating machine are common printing and packaging machinery, the coating machine is mainly to evenly adhere glue or ink substances to the surface of aluminum foil, plastic film or cloth textiles, and the laminating machine is a special equipment used for paper, plate, laminating film to form products into a combination of paper and plastic, and rollers play an important role in these two types of machinery.

With the further penetration of carbon fiber composite materials in the industrial field, the advantages of carbon fiber rollers are becoming more and more prominent, and the trend of replacing metal rollers is becoming more and more obvious.

The main advantage of carbon fiber composites comes from the physical properties of carbon fibers with high strength and low density. The most obvious point is that the lower weight of the carbon fiber roller can provide higher speed, the weight of the carbon fiber roller is only about 30% of the steel roller, its critical speed is usually twice that of the corresponding steel roller; if the metal roller wants to increase the width, it must consider the increase of the weight of the roll and the deflection of the roller body, the light and high-strength carbon fiber roller can easily help the machine to achieve a wider working range, and once the amplitude is widened, the output is bound to increase exponentially; and the lighter roller body needs less starting time, due to the lower inertia, the device starting time can be greatly reduced, and the production efficiency is higher.

In some cases, many guide rollers do not need power, due to the weight and light weight of the film to be driven, in order to avoid stretching or damage, metal guide rollers usually need to be driven and controlled by complex electronic systems, but lightweight carbon fiber rollers can be operated smoothly without motors, electronic drives, control systems, etc. The carbon fibre material keeps the weight of the oscillating and loaded rollers low, which means that the actual film tension can be read more accurately and run faster with a smaller load unit.

Compared with steel rollers, aluminum rollers can reduce a large part of the weight and also have certain advantages, but carbon fiber rollers can not only reduce weight and moment of inertia, but also their designability can meet many different needs, and the stiffness is also better, with the increase in size, this difference is more obvious. Although the cost price is higher than that of aluminum rollers, this one-time cost increase is insignificant considering the lower material consumption, higher product quality and production efficiency.

The carbon fiber rollers for coaters and laminators are made of prepreg tube reel technology and can provide a surface with carbon fiber fabrics. In this case, its wear resistance is far superior to that of aluminum surfaces, and even better than anodized aluminum, and the surface hardness is also higher than that of aluminum rollers. For example, carbon fiber rollers can be treated with different types of coatings as needed, and the appropriate coating can improve the overall application value of the rolls. For coating machines and laminating machines, the reasonable choice of coating can effectively avoid the web from sticking to the surface of the roller body, such as the thermal spraying method of using silicone to seal high roughness.

Compare the application value of carbon fiber roller aluminum roller:

The first is the issue of start/stop speed, which theoretically has three factors that affect the start and stop speed: the moment of inertia of the guide roller, the wrapping angle of the web, and the friction coefficient of the guide roller surface. One of the most important factors is the moment of inertia of the guide roller, the lighter the guide roller, the less torque required, and the easier it is to drive the guide roller to rotate and accelerate. Compared to conventional aluminum rollers, the moment of inertia of carbon fiber rollers is reduced by an average of 2.5-3 times, thus reducing start-up and downtime by more than 50%.

The second is the problem of wear resistance, in the normal operation of the machine, the less friction of the bearing, the less the impact on the web. For delicate films, the weight of the guide roller becomes the dominant factor affecting the size of the bearing due to the low tension of the web. The lighter the weight of the guide roller, the smaller the bearing required and the less friction is generated. In practice, it has been found that carbon fiber guide rollers are much more durable and wear-resistant than aluminum rollers because they have better vibration damping, allowing machine bearings to have longer maintenance intervals.

In the comparison of product quality, it was found that in the processing process of low-tension stretch materials such as PE or CPP, the use of carbon fiber rollers greatly improved the rotation speed, and the previous roller slippage hindered the rotation of the web paper or kept it in a rotating state, so that the metallized OPP and PET films were seriously damaged and scratched, and after the use of carbon fiber rollers for replacement, scratches and other problems no longer appeared.

Previous: What Are The Performance Advantages Of Carbon Fiber Guide Rollers On Lithium Battery Winders