Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

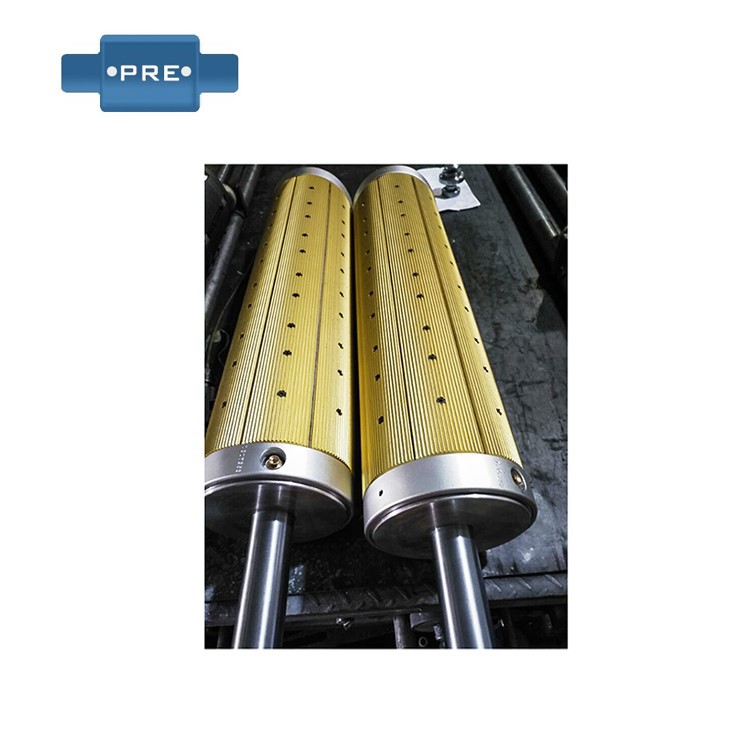

Air Expansion Shaft: It is a kind of special winding and unwinding shaft, the surface part of which can be expanded after high pressure inflation, and the surface part of which can be quickly retracted after deflation is called Air Expansion Shaft, Air Pressure Shaft, Expansion Shaft, Expansion Shaft, Air Expansion Roller, Inflatable Shaft, Pressure Shaft, and so on.

Air expansion shaft is extremely convenient and quick to use, only the user to provide their own air source, air pressure control in the range of 6-8kg, the need to lock the reel core, as long as the air gun to the air expansion shaft on the air nozzle inflatable can be accomplished, the need to relax the reel core unloading, by hand, press down on the nozzle on the sliding core of the air that is deflated.

Expansion shaft specifications: 1 inch, 1.5 inches, 2 inches, 2.5 inches, 3 inches, 6 inches, 8 inches, 10 inches, 12 inches, gas expansion sleeve clamps, etc., according to customer demand for processing and production of different specifications of the gas expansion shaft.

Air Expansion Shaft Working Principle: It is a kind of special rewinding and unwinding shaft, that is to say, the shaft that can be inflated after high-pressure inflation, and the shaft that can be quickly retracted after deflating the surface part is called air-expanding shaft. Users only need to provide their own air source, air pressure control in the range of 6-8 kilograms, the need to lock the reel core, as long as the inflatable handle against the air nozzle on the air expansion shaft can be completed, the need to relax the reel core unloading, by hand, press down on the nozzle on the sliding air core can be deflated. All the machines and equipments which are used for reel winding and unwinding can be applied with the air expanding shaft.

Characteristics of air expanding shaft:

1) air shaft inflation operation time is short: air shaft and paper tube separation and placement of only 3 seconds to complete the inflation and deflation, the air shaft does not need to decompose the shaft end side of any parts that can be tightly with the paper tube bite.

2) Simple placement of the paper tube by the pneumatic shaft: with the action of inflating and deflating, the pneumatic shaft can move and fix the paper tube in any position on the shaft surface.

3) air up bearing capacity: according to the actual needs of customers, to determine the size of the shaft diameter, and the use of high hardness steel, so that the load capacity increased.

4)High economic efficiency: the shaft is designed for special function, the air up shaft can be applied to all kinds of paper tubes which are thick, thin, wide and narrow.

5) air up shaft maintenance is simple, long use time: although the air expansion shaft is a mechanical accessory, but its own structure of each part are fixed specifications, can be used interchangeably, so that it is easy to maintain.

The production process of gas expansion shaft:

1) Matching, loading, welding: Matching car inner tube, scale and outer tube interference 0.4mm, two plates inverted weld angle 15X30 degrees, grinding inner tube, slag, check the inner tube scale and outer tube diameter scale is not compatible, hot set in place, to be cooled and contracted, the whole group welding.

2) annealing, rough turning, quenching: annealing heat treatment, air expansion shaft technology tempering, multiple de-stressing, rough turning to leave a margin, do static balance, more than 50g, the need to account for borrowing bias, on the lathe borrowing.

3) Dynamic balancing, plating, fine grinding: the air expansion shaft to do dynamic balancing G40 level, sealing the ventilation holes, do the pressure test without leakage, do the hydrostatic evacuation test. Electroplating hard chrome, air expansion shaft fittings on one side 0.15 chrome layer uniformity without pinholes, fall and other shortcomings.

4) Sanding, fine grinding mirror surface: air expansion shaft with disc grinder sanding air expansion shaft fittings, check air expansion shaft fittings, no water ripples, spiral pattern, pinhole, fly rent and other flawed quality.

5) Component welding: gas expansion shaft group welding inner plate, head, bushings, plug plate, inner tube, etc., inner tube to do static balance within 50g, inner tube to draw a line of rotation, welded flat steel runners.

6) Precision turning, rough grinding: two shaft head to repair the top pin hole, two shaft head to the gas expansion shaft fittings jump.

The application of air-expanded shaft in the machine and equipment:

Air expansion shaft has a wide range of uses, where there are winding, unwinding, slitting machines, can be applied to air expansion shaft, even including light metal industry. Such as: air expansion shaft is mainly applied to printing equipment: sun board machine, flexographic printing machine, gravure machine, trademark printing machine, etc.; other machinery: coating machine, leather machine, shaping machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, papermaking machine, non-woven fabrics, fabric inspection machine, hot stamping machine, battery equipment, and other related machinery. Matching use.

Six common causes of air leakage from pneumatic expansion shafts:

1) Rupture of the airbag of the pneumatic expansion shaft due to long time use, which affects the function of use;

2) The key bar on the shaft breaks or the spring plate or screw falls off and pierces the airbag;

3) The head of the pneumatic expansion shaft is broken because the worker throws or puts the pneumatic expansion shaft carelessly in the process of using the machine, so it is necessary to replace the head of the pneumatic expansion shaft;

4) Because of the long time use, the air expansion shaft key bar and the paper tube contact surface wear for a long time, resulting in the air expansion shaft key bar wear, so as to be unable to fix the paper tube, which needs to replace the air expansion shaft key bar;

5) Because of long time use, all the spring plates inside the air expansion shaft are broken, so that the key bar of the air expansion shaft can not return to the normal use;

6) The air nozzle is leaking because of long time use, so it is necessary to replace the air nozzle of the air expanding shaft.

When customizing, you need to confirm the load capacity of the shaft:

1) Size of shaft diameter and support capacity

The size of the shaft diameter can be adjusted according to the actual needs of the customer. This adds to the advantage of ease of use. The stability of the inflatable air pressure promotes the accuracy of the size specification of the shaft diameter and the size of the capacity that can be supported.

2) Hardness of steel

For the air expansion axis of the material selected, is to be carried out in the selection of high-quality and high hardness of steel. It is able to improve the effect of supporting the expansion of the pressure and effectively promote the load capacity.