Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The pneumatic expansion shaft is an indispensable and important component in modern laminating machines. With its powerful inflatable function, it supports the efficient operation of the laminating machine, helping manufacturers to produce high-quality products and maintain competitiveness in the market. Today, we're going to take a look at the application of an inflatable shaft in a laminating machine and why it's so important.

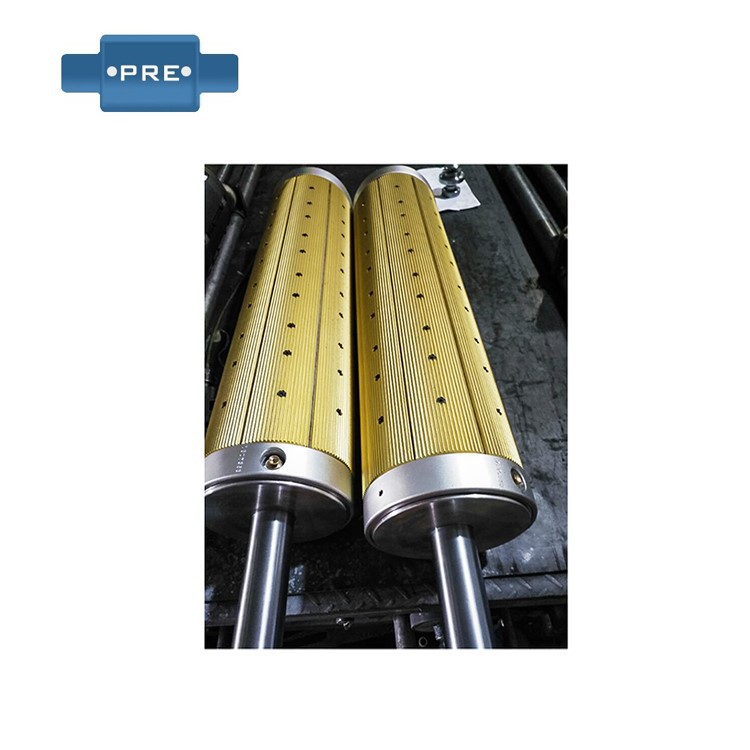

Inflatable shaft, also known as air expansion shaft, inflatable roller, air pressure shaft, inflation shaft, expansion shaft, flatulence shaft, pressure shaft, is a special winding and unwinding shaft, that is, the shaft that can be protruded on the surface after high-pressure inflation, and the shaft that can be quickly retracted on the surface after deflating. All machines for winding and unwinding can be applied to inflatable shafts, which can be up to six meters or more, and as short as several hundred millimeters, all of which are determined according to customer needs. It can be divided into three forms: key inflatable shaft, through-bar inflatable shaft and plate inflatable shaft.

1) Key inflatable shaft

The shaft body is made of high-quality steel tube, chrome-plated surface, aluminum convex key is flexible and flexible, equipped with high-quality rubber liner and quick filling and exhaust nozzle, good sealing effect, long service life, detachable shaft head, easy maintenance. The key inflatable shaft expands up a single key bar, and the fulcrum spreads to each key bar to balance the force, and the unilateral expansion height can reach 5mm to 6mm after inflation, which can be applied to items with heavy mechanical winding capacity.

2) Plate inflatable shaft

The expansion part is a plate, the fulcrum is evenly dispersed, the force is uniform, and the expansion height can reach 4mm to 5mm, which can be applied to machinery with high winding precision or lighter winding items.

3) Through-bar inflatable shaft

a. The three-inch shaft is 5 separate airbags, and the six-inch shaft is 8 separate airbags, which is not easy to leak and simple to maintain;

b. The inflation area of the whole key bar is similar to that of the tile inflatable shaft, but there will be no tile inflatable shaft, and the inflatulating part is easy to deform;

c. The area of the key bar is better than that of the key bar type inflatable shaft;

d. The key strip is made of wear-resistant rubber, which is not easy to damage the paper tube and has a stronger grip;

e. The shaft body is made of high hardness alloy, which has high hardness and weight reduction of 30%-40% compared with ordinary materials, and the weight is lighter to use.

Introduction to the characteristics of the inflatable shaft:

1) Wide application: inflatable shaft as an independently designed part, from 1 inch --- 12 inches, the length and size are determined by the actual needs of customers, where there are slitting, printing, rewinding, coating, laminating, bag-making, papermaking and other work equipment or other related center coiling machinery, can be applied to the factory inflatable shaft.

2) Cost-effective and efficient: The design of the inflatable shaft is designed for the actual work needs, and it can be applied to various types of coiled pipes such as thickness, thinness, width and narrowness.

3) Long use time, simple maintenance: although the inflatable shaft is a mechanical accessory, every part in its own structure has a fixed specification, can be used interchangeably, so that it is easy to maintain. Our factory has strict requirements for the quality of the accessories of the inflatable shaft, and the product quality is absolutely guaranteed.

4) Single accessory: The inflatable shaft is a single spare part of the winding and unwinding machinery, and each part in its structure has a fixed specification and size, which can be decomposed and combined, so that the maintenance is convenient and durable.

Uses of inflatable shafts:

The use of inflatable shaft is very wide, and all machines with winding, unwinding and slitting can be applied to inflatable shafts, even including light metal industries. For example, the inflatable shaft is mainly suitable for printing equipment: drying machine, flexo printing machine, gravure machine, trademark printing machine, etc.; other machinery includes: coating machine, leather machine, setting machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, cloth inspection machine, hot stamping machine, battery equipment and other related machinery supporting the use.

Find out what a laminating machine is:

Extrusion casting machine, some manufacturers and users in the industry are accustomed to call it laminating machine, also known as extrusion molding machine, casting machine, extrusion casting machine, casting machine, coating machine, coating machine (inaccurate, actually refers to hot melt glue scraper coating machine), is a kind of extrusion molding machinery.

It has the advantages of high degree of automation, easy operation, high production speed, uniform coating thickness, high adhesive fastness, smooth coiling, environmental protection and pollution-free, saving labor and raw material costs, etc., which has developed mature in Europe and the United States, and has gradually begun to be applied in China in recent years, which is the inevitable trend of replacing dry composite and hot melt adhesive coating composite.

Why is the inflatable shaft so important in the laminating machine? There are several main reasons:

1) The inflatable shaft can effectively control the coil tension, so as to ensure the consistency and quality of the product. In the production process of the laminating machine, the tension of the coil is very critical. If the tension is too high, it is easy to cause cracking, deformation or tearing of the material, which will affect the appearance and performance of the product, and if the tension is too low, it is easy to lead to low production efficiency and thus increase operating costs. As a powerful tension controller, the inflatable shaft can help manufacturers solve these problems and improve the consistency and quality of products.

2) The inflatable shaft can reduce the loss and waste in the production process. In the production process of the laminating machine, if the tension of the coil cannot be effectively controlled, it is easy to cause material waste and loss. Sometimes it can even lead to downtime in the production process due to material waste. The use of inflatable shafts can be very effective in avoiding these problems, thus reducing losses and waste.

3) The inflatable shaft has very good versatility and applicability, and can be applied to a variety of different types of materials and coils. Laminators have a wide range of applications and need to handle a wide range of different types of materials and coils. Some materials have different properties and properties and require different methods to be treated. The versatility and applicability of the inflatable shaft allows it to be applied to a variety of different types of materials and coils to meet the different needs of manufacturers.

![]()

Surface rotating slatted air shaft

Surface rotating key type air shaft

Center guide slat-type air shaft

Center guide lug-type air shaft

Individual independent adjustment of the slip type air shaft

Previous: The Role Of Air Valves in The Air Pneumatic Shaft

Next: How Much Do You Know About Multi Bladder Type Air Expanding Shaft