Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

New energy is a hot topic in recent years, which includes the field of lithium batteries, lithium battery production equipment, the use of roller guide roller products, this equipment began to operate, are imported, see the use of carbon fiber guide roller, all this kind of winding machine

The guide roller has been made of carbon fiber material, which is actually because of the performance advantages of carbon fiber guide rollers, so let's talk about the high-performance advantages of this product.

Why can carbon fiber rollers be used in the lithium battery industry?

Carbon fiber roller is a very important part of the production process of lithium battery, it can be used as a roller on lithium battery equipment, and it is a very important rotary part on the lithium battery winding machine. The high precision requirements for this component and therefore the need to be as lightweight as possible, and the carbon fiber rollers are ideally suited to this need.

In the production process of lithium battery, it is necessary to have a high degree of balance in the roller to ensure that every tiny centrifugal inertia cancels each other out when rotating, and reduces the generation of vibration and noise, which is a very important component to improve the production efficiency of lithium battery. Originally, most of the steel rollers and aluminum alloy rollers were used, but their dead weight was larger and the accuracy was lower, and the advantages of carbon fiber rollers in this regard were very obvious, which could maintain high accuracy and balance and avoid runout in the production process.

The weight of the carbon fiber roller is more than 70% lighter than the steel roller, about 40% lighter than the aluminum alloy roller, and it has several times the tensile strength of the two, which can better improve the production efficiency and safety in actual use.

The carbon fiber guide rollers on the lithium battery winder have the following performance advantages:

1) The carbon fiber roller of the lithium battery winding machine plays a very good performance in the production, then at this time, we find that the whole mass of the carbon fiber roller is lighter, because the density of the carbon fiber material is only 1.6g/cubic meter, which leads to the overall weight of the carbon fiber roller

High, more convenient to use, lower energy consumption, and for this product with very high dynamic balance performance requirements, it can better complete the standard of dynamic balance.

2) In addition, the carbon fiber roller has extremely high strength, and the tensile strength of the carbon fiber material itself can reach 3500MPa, which makes the fiber guide have very good strength and performance in the production of batteries, which is not allowed for carbon maintenance in high-speed long-distance rotation

It is easy to deform, if it is a metal guide roller, it will be significantly deformed at 1376Nm, and the carbon fiber roller will be damaged when the torque reaches 4700Nm, which can make the fatigue resistance of the carbon fiber guide better.

3) The corrosion resistance of our carbon fiber roller is better, it has the performance advantage of very good acid and alkali resistance and corrosion resistance, and the electrochemical property of the whole is relatively low, which makes the durability of the carbon fiber roller better, and the corresponding service life is also smaller.

These three points can be said to be the outstanding performance of the battery winder using carbon fiber rollers, and the reason why carbon fiber rollers are chosen instead of metal guide rollers, which have very good anti-aging performance, as well as the reason why the processability of the design includes a low coefficient of thermal expansion, which makes the application advantages of carbon fiber rollers have been improved.

Background overview of the use of carbon fiber guide rollers:

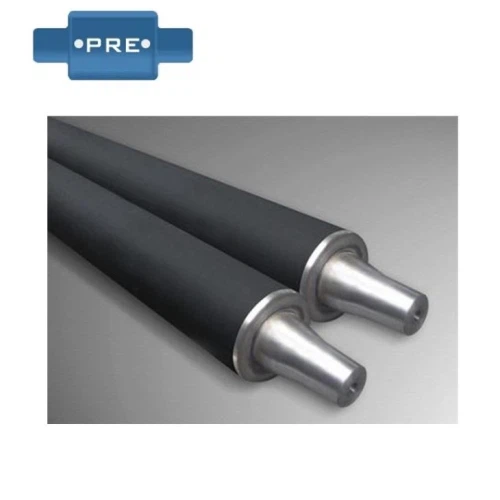

The guide roller can be said to be a very important part of the paper machine, with many functions, such as support, relying on the driving force or operation of the forming mesh and transmitting the net, and it can also play the role of correction and tensioning. In the past, the wet-end guide rollers of paper machines consisted of a roller body and rollers at both ends of the roller body, and the roller body was usually made of stainless steel or aluminum alloy material. The stainless steel guide roller is heavier, and the aluminum alloy is lighter, but the strength is slightly weaker.

The outer surface of stainless steel guide rollers and aluminum alloy guide rollers often has a layer of rubber covering, which is mainly composed of rubber, polyurethane and other composite materials. Because of material factors, the service life of the lagging layer is not too long, often about 2-3 years, and the lagging layer needs to be ground and maintained halfway. Is there a substitute for other materials of guide rollers? Here we will talk about today's protagonist carbon fiber guide rollers.

What other industries can carbon fiber rollers be applied to?

Lithium battery is a relatively good product in the new energy industry and is an indispensable power source for new energy vehicles. In fact, carbon fiber rollers can not only be used in the new energy industry, but also for many traditional industries, let's take a look at the following industries.

1) Paper and film industry: roll products, such as paper, film, aluminum foil, etc., in the production process, width and linear speed are important factors affecting production efficiency. The width of the carbon fiber roller can be longer, the critical speed can be higher, and the advantages of mechanical properties allow it to achieve higher production efficiency.

Carbon fiber rollers for paper machines:

Compared with ordinary metal rollers, carbon fiber rollers are light in weight and high strength, which can greatly reduce the weight of the roller and reduce the weight of the paper machine equipment as a whole. If the weight of the roller is too heavy or the speed is too fast, it will cause the deflection of the roller to increase, and then cause the damage of the rubber coating layer on the surface of the roller and the fracture of the roller shaft head, etc., the use of carbon fiber roller can effectively reduce this problem, especially in the case of wide paper width, the performance advantage of carbon fiber roller is more obvious.

On the other hand, carbon fiber composite materials have strong corrosion resistance and fatigue resistance, and the strong corrosion resistance of carbon fiber can also resist the corrosion of polyvinyl acetate glue, which is very convenient for maintenance and cleaning. The rollers made of this material have a long service life, can adapt to a large working temperature difference, and have a high degree of portability in installation and disassembly, which can reduce operating costs to a certain extent. In paper mills that require machines to run at high speeds for long periods of time, the frequency of part damage and repairs can be reduced, which is positive for production safety and productivity.

2) Printing industry: Industrial printing has played an important role in promoting the development of modern civilization, but the printing industry itself is an industry that is constantly repeated and requires high durability of equipment. If you want to maintain the speed and efficiency of the printed product, you have to make the press last longer, and print faster and more accurately. The carbon fiber roller has light weight, low friction between the rollers, small inertia, and room for improvement in printing speed, coupled with the characteristics of carbon fiber roller such as wear resistance, corrosion resistance, and small thermal expansion coefficient, which can maintain a long-term high-load working state and prolong the service life.

Carbon fiber rollers for printing presses:

In printing machinery, vibration has a direct impact on print quality – the higher the vibration, the worse the final print quality. Studies have shown that the magnitude of this vibration is related to the elastic modulus (stiffness) of the roll material itself.

Conventional steel rolls perform well at normal speeds, but as the machine runs at higher speeds, the vibrations increase. To improve the situation, the engineers of the printing machinery began to use carbon fiber composite rollers instead of steel rollers. Because the stiffness of carbon fiber is significantly higher than that of traditional metal materials such as steel, it not only has low vibration, but also can carry the strong torque and tensile force brought by high speed, and when the machine runs at a certain speed, this advantage of carbon fiber roller is more and more obvious.

3) Spinning machinery industry: textile materials are constantly reciprocating on machinery, and flying flowers, cotton miscellaneous, dust, oil stains, etc. are easy to cause certain corrosion damage to the machinery and reduce the work efficiency of textile machinery. As an important component, if the roller does not have a certain corrosion resistance, it will have a certain impact on the production capacity. Carbon fiber rollers perform significantly better than metal rollers in this aspect, and the metal roller shaft will also have the problem of oxidation and rust, which can also be avoided by carbon fiber rollers.

With excellent mechanical properties, carbon fiber rollers have opened up the situation in traditional industries and new energy industries, and carbon fiber products with high strength and high modulus can also be used in cutting-edge fields such as aerospace, which shows that the application value of carbon fiber materials is very high. With the upgrading of the domestic carbon fiber industry and technology, carbon fiber products will appear more in our lives in the future.