Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

About the web guiding control system:

1) The working principle of the correction control system: the correction control system is an automatic closed-loop system that automatically corrects the lateral deviation of the coil, detects the relative position of the edge of the coil through the correction sensor, and then the control system compares the deviation of the detected value and the set value, and sends a signal to the electric drive for correction.

2) Components: controllers, electric drives, sensors, and guiding parts.

3) Product classification: deviation correction integrated machine, deviation correction split machine.

4) Detection method: edge inspection, line inspection, centering.

5) Application of Guiding Control System:

Applicable industries: printing, packaging, papermaking, non-woven fabrics, lithium batteries, solar energy, rubber tires, textiles, metallurgy, etc.

Applicable coil material: web paper, film, metal foil, film, leather, non-woven fabric, weaving and other winding materials.

Applicable Equipment:

Printing and packaging: flexo printing machine, gravure printing machine, rotary printing machine, label printing machine, slitting machine, coating machine, laminating machine, inspection machine, die-cutting machine, film blowing machine, bag making machine, etc.

Non-woven fabrics: sanitary cloth equipment, sanitary pad production line, baby diaper production line, medical accessories production line, etc.

Lithium battery: electrode piece coating machine, pole piece rolling mill, slitting machine, winding machine, etc.

Rubber tires: extruders, cord production lines, presses, cutting machines, molding machines, etc.

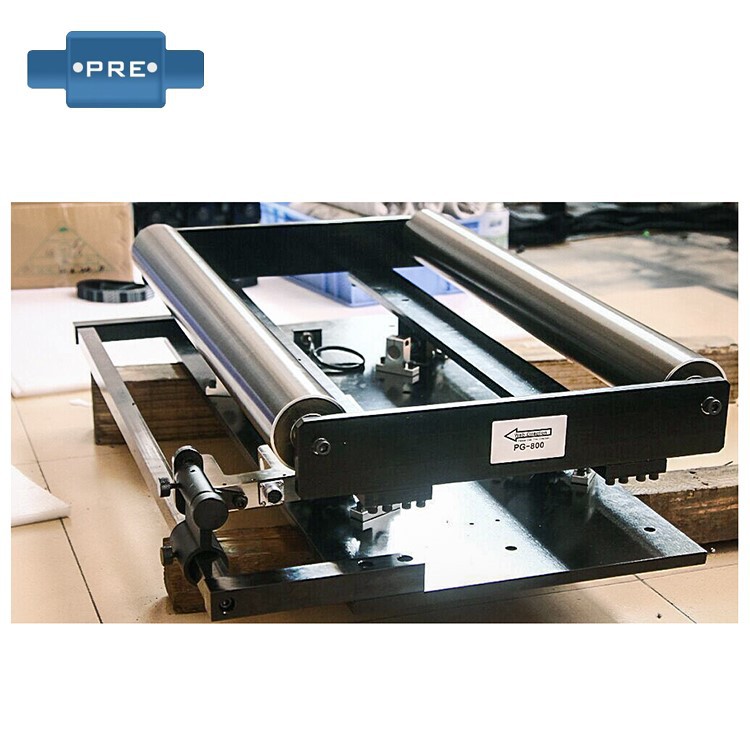

Selection of guide rollers of the guide roller of the correction machine:

1) The coil material is afraid of scratches, so choose an aluminum guide roller with a smooth surface, which will not damage the material;

2) If the coil needs a certain friction, you can choose to wrap the veneer guide roller, so that the coil will not slip when passing through, which will affect the correction effect;

3) The coil material is sticky, for example, the high-temperature tape needs to be laminated to another material, then you can choose the guide roller with Teflon surface treatment, and the adhesive tape will not stick when it passes.

Selection of the sensor of the guiding all-in-one machine:

1) There are many types of sensors, and the corresponding sensors are selected according to the material of the coil; For example, the ultrasonic sensor converts the ultrasonic signal into an electrical signal, which is suitable for the use of impermeable coils, such as tapes, films, etc.;

2) Photoelectric sensor: a sensor that uses a photoelectric element as a detection element; It converts optical signals into electrical signals and is suitable for breathable coils, such as non-woven fabrics;

3) Photoelectric sensor and ultrasonic sensor are more commonly used and easy-to-use sensors of the correction all-in-one machine, with high detection accuracy, good environmental adaptability, and simple installation and operation.

Functional characteristics of the all-in-one servo guiding system:

1) Brushless servo motor drive, maintenance-free.

2) Precision ball screws.

3) The guide stroke is large.

4) The length and span of the guide roller can be customized.

5) The guide roller can be equipped with hard anodizing layer, rubber layer, and cork veneer.

Technical parameters of all-in-one servo guiding system:

1) Support three working modes: chasing line, chasing edge, and pairing.

2) Intelligent detection of sensor parameters, no need to calibrate the sensor in most environments.

3) Automatic stroke measurement, no need for mechanical limit switch.

4) Adopt FIR digital filter, differential filter, stronger anti-interference ability, more stable signal.

5) DC servo motor pushes the ball screw.

6) All system status parameters are remembered for power-off.

7) Chinese Simplified Chinese/Chinese Traditional/English trilingual menu operation.

8) User-friendly operation, fast and easy.

9) Support Modbus and PLC/HMI network control.

Problems and solutions of the correction all-in-one machine in automatic mode:

1) The all-in-one machine has manual mode and automatic mode, after the general parameters are set, click on the automatic mode, put on the coil, and you can automatically correct the deviation;

2) However, if the deviation cannot be corrected in automatic mode, there may be these reasons: check whether the sensor is wired correctly;

3) Check whether the type of sensor is selected correctly on the operating system of the correction all-in-one machine; Ultrasonic, optoelectric, CCD options available;

4) Check whether the polarity selection of the correction all-in-one machine corresponds, the easiest way is: when the polarity is positive, the polarity can not be corrected normally, and the polarity is negative; Vice versa;

5) If the sensor is photoelectric, it needs to be calibrated.