Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The most basic data to be provided:

1) Size requirements: Provide the exact size of the guide roller, including diameter, length, width, and possible deviation range. These dimensions should be determined based on the actual application needs.

2) Material requirements: determine the grade and specifications of the aluminum to be used. According to the application environment and requirements of the guide roller, the appropriate aluminum alloy material is selected, for example, based on factors such as strength, wear resistance, corrosion resistance and thermal conductivity.

3) Overall structural requirements: According to the application requirements, determine the overall structure of the guide roller, such as whether bearings, shaft hole diameters, axial hole design, threaded holes and other special requirements are required.

4) Surface treatment requirements: determine the surface treatment method of the guide roller, such as anodizing, spraying, sandblasting, polishing, etc. Surface treatment can improve the wear resistance, corrosion resistance and aesthetics of the guide rollers.

5) Load requirements: provide the load and working conditions of the guide roller, so as to determine the appropriate strength and bearing capacity of the guide roller.

6) Environmental requirements: determine the working environment of the guide roller, such as temperature range, humidity, corrosive environment, etc. These factors affect the material selection and surface treatment of the guide rollers.

In order to achieve the best flattening effect, the arc roll should be selected more strictly to achieve the best matching effect. The following parameters need to be provided:

Type of machine:

Roller position:

Linear speed: m/min

Web tension: kg/cm

Material: (e.g. paper, film, foil, others, etc.)

Paper weight: gr/m2

Film thickness: mm

Working temperature: °

Web width: mm

Face: mm

Support:

Axis Table Base Type / Flange Type

Spreader covering:

rubber/metal /Teflon

Spreader type

Fixed Bow/Variable Bow

Banana guide rollers are also known as: printing and dyeing bending rollers, arc rollers, flattening rollers, bending rollers, printing and dyeing rubber rollers, rubber rollers, papermaking rubber rollers, nitrile rubber rollers, textile rubber rollers, printing rubber rollers, coating machine rollers, bending rollers, and expansion rollers.

Definition of Banana Guide Roller:

The curved roller has a figurative metaphor for the "banana roller", and it is clear that the name comes from its shape. The arc roller is roughly composed of three parts: the mandrel, the roll surface, and the support. The mandrel is fixed when it works, and is the carrier of the whole roll, and the angle can be adjusted by support. The roller surface is composed of a series of roller sleeves, bearings, connectors, etc. that can be rotated briskly, and there will be a layer of rubber sleeve outside the curved roller of the rubber surface, and the rubber sleeve material and formula used are different according to different occasions.

The main function of the curved roller is to remove the wrinkles and relaxation of the strip while making the necessary expansion.

The core of the design of the curved roll is to completely diverge the tension in the material, in a state of dynamic equilibrium, to remove the wrinkles of the material, so that the swollen or loose edge tension is evenly maintained and flat.

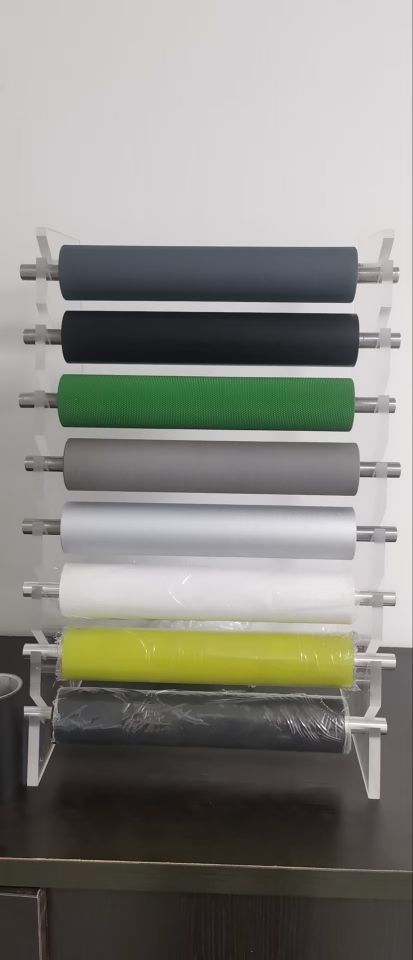

Depending on the application, the rubber sleeve is generally made of the following materials:

1)Nitrile rubber

Nitrile rubber can be widely used mainly because of its excellent comprehensive performance and relatively high cost performance, but the disadvantage is that the wear resistance and high temperature resistance are poor, so it is easy to age.

Suitable models are: slitting machine, coating machine, rewinding machine and other equipment in conventional environments.

2)EPDM rubber

The degree of temperature resistance and anti-aging is better than that of Ding Nile, and some of the properties are inferior.

3)Silicone

Silica gel has a stable molecular structure, its temperature resistance and wear resistance are outstanding, and because of its safe and non-toxic characteristics, it has an irreplaceable role in medicine, food and other fields.

Suitable models are: winding vacuum aluminizing machine, medicine, food machinery.

4)Polyurethane

The outstanding property of polyurethane is that it has super wear resistance, so it is more suitable for harder substrates, such as non-ferrous metals, steel, etc

Suitable models are: strip steel and aluminum strip seam separator

5)Teflon

Teflon rubber sleeve is commonly known as heat shrinkable tube, which has the characteristics of drug resistance, tack, anti-static and so on

It is more suitable for the wet end of papermaking machinery, gluing and chemical environments.

Of course, in order to improve the performance of the rubber sleeve and meet customer requirements, different formulas will be adjusted, and its internal structure will also be adjusted accordingly, such as winding wire, cord cloth, steel wire, etc. to improve strength and plasticity.

Classification of arc rolls:

According to the material of the roll surface, the arc roller can be divided into the curved roller with rubber surface, the curved roller with the surface and the arc roller of other materials (such as surface installation or spraying Teflon layer)

According to the structure, the arc roller can be divided into fixed arc height and adjustable arc height arc roller.

Arc rollers are generally divided into two categories: active rollers and driven rollers. The driving arc roller is equipped with a pulley and other transmission devices on one side of the arc roller, and the driven roller is driven by the friction between the material itself and the roller surface. All rolls require a critical physical acceleration called inertia at start-up. The roll must not work due to the size of the inertia.

The weight reduction of the rotating part makes it easier to make the starting inertia of the arc roll superior, and it is not easy to slide relative to the material. In general, the best flattening effect can be achieved by the active plus passive method.

The curved roller with adjustable bow height has the following advantages: The optimal amount of bending can be set even if the type, thickness, width, tension, etc. of the base material changes.

Installation and arrangement of curved rollers:

In order to achieve the best stretching effect, a certain length should be maintained between the introductory roller and the arc roller. The distance between the deriving roller and the curved roller should be as short as possible.

1) The distance between the lead-in roll and the arc roll is at least 2 times the distance between the deriving roll and the arc roll.

2) The distance between the roller and the arc roller is up to 2 times the diameter of the roller.

Rubber bending roller use: widely used in textile, printing and dyeing, printing, printing, papermaking, metallurgy, transportation, plastics, leather, tobacco, pharmaceutical, wood, packaging machinery and equipment and other industrial machinery, with high wear resistance, high elasticity, oxidation resistance, corrosion resistance, high temperature resistance, strong acid and alkali resistance, strong solvent resistance.

Previous: China Factory Conveyor Rollers, More Favorable Price For Large Quantity

Next: How To Achieve Scratch Resistance, Anti-sticking And Firmness Of Aluminum Rollers?