Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

In the rewinding, unwinding, and slitting machines, the inflatable shaft has become an indispensable tool. The inflatable shaft is the shaft that can protrude on the surface after high-pressure inflation, and the shaft where the surface part is retracted after deflating. Commonly used inflatable shafts are divided into slip shafts, key-bar inflatable shafts, and slat-type inflatable shafts. As for the most commonly used key-type inflatable shaft and slat-type inflatable shaft, do you know the difference between them?

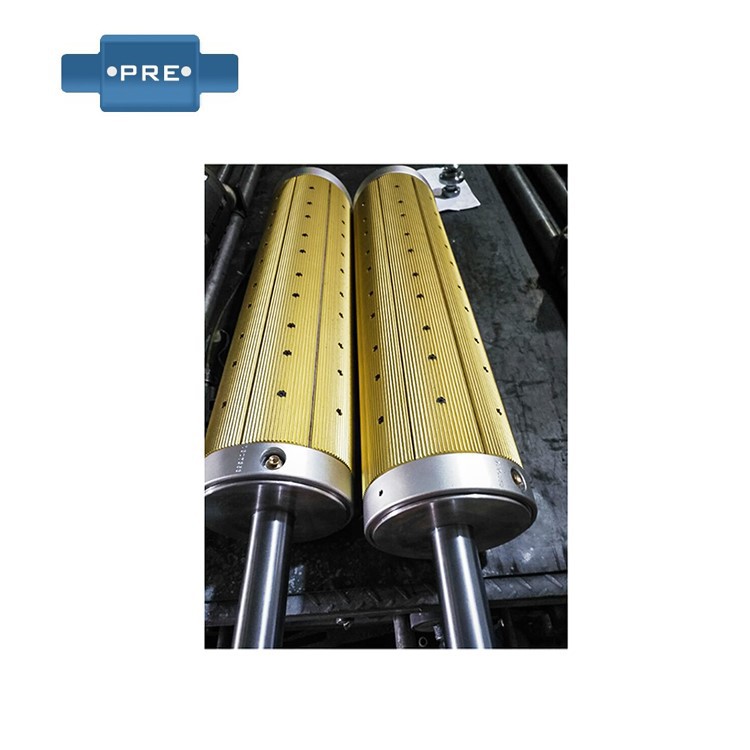

First of all, the keybar inflatable shaft is also called the convex key inflatable shaft, the key bar inflatable shaft, the convex claw inflatable shaft, the claw key inflatable shaft and other names, the key bar inflatable shaft expands up to a single keybar, the fulcrum spreads to each keybar, and the balance is stressed, usually the unilateral expansion height can reach 5mm to 6mm, such as the diameter before expansion is 74mm to 75mm, and the diameter after expansion can reach 79mm to 82mm, special expansion height, separate requirements. 3 inch key type inflatable shaft, usually using coil tube with an inner diameter of 76mm.

The inflatable shaft can be applied to the mechanical winding and unwinding of heavy items, such as: cloth, film, printed matter, composite materials, etc., and the suitable machines are coating machines, rewinding machines, laminating machines, paper machines, bag making machines, plastic machines and other related machinery rewinding and unwinding scrolls, which can effectively improve work efficiency.

There are generally a variety of sizes of keybar inflatable shafts, including 1 inch, 1.5 inch, 2 inch, 2.5 inch, 3 inch, 6 inch, 8 inch, 10 inch, 12 inch, etc., and can also be processed and produced according to the demand for different specifications of the inflatable shaft (inflatable shaft).

Structural characteristics of lug type pneumatic shaft:

The convex key inflatable shaft (pneumatic shaft) is a key inflatable shaft. The shaft body of this type of inflatable shaft is made of high-quality steel tubing with a hard chrome surface and aluminum convex keys. Filling and exhaust nozzle, good sealing effect, detachable shaft head, easy maintenance, long service life. The convex key inflatable shaft is widely used in slitting, mixing, printing, coating, bag making, papermaking and other mechanical winding shafts, which effectively improves the work efficiency and overall product quality.

Key inflatable shaft maintenance method:

1) Rubber hose leakage: This phenomenon is that the quality of the hose itself is not enough. After installation, it will leak when inflated.

2) There is a gap in the sealing ring: install the sealing ring and spray a circle of sealant.

3) Air nozzle leakage: The inflatable nozzle is not installed correctly, so just replace another inflatable nozzle and install it.

4) Broken hose: If so, it's troublesome. It is necessary to remove the axle head and replace it with a new hose.

Nine precautions for installing a keyed inflatable shaft:

1) Be familiar with the construction drawings and site conditions, and formulate a detailed construction plan.

2) It is necessary to be proficient in the way, method and skills of laying and installation of key inflatable shaft, and understand the precautions in the construction, such as the bending radius of the inflatable shaft, the arrangement of laying, how to enter and exit the distribution box and cabinet, and how to pay attention to eliminating eddy current.

3) Familiar with the supporting accessories of the key inflatable shaft, as well as the installation and use of each accessory.

4) After the key inflatable shaft is laid, if there is no intermediate joint, you can directly do the terminal head, if there is an intermediate joint, then you should do the intermediate joint first, otherwise it will increase the troublesome work such as checking the phase.

5) Understand the special tools required for the installation and construction of key inflatable shafts and be proficient in their use.

6) During the laying of the key inflatable shaft, or after the laying is installed, it must be strictly forbidden to drag or collide with the live welding faucet wire on the key inflatable shaft.

7) Have a comprehensive understanding of the structure, performance and characteristics of the key inflatable shaft, and understand the model, specification, type and adaptation place of the inflatable shaft.

8) The copper sheath of the key inflatable shaft can be used for grounding, and it must be grounded.

9) In the process of laying and installation, the insulation of the key inflatable shaft should be tested diligently, and the problems should be dealt with in time.

The slatted inflatable shaft is also called the tile inflatable shaft, the slatted inflatable shaft expands the whole plate, the fulcrum is evenly dispersed, the force is uniform, usually the expansion height can reach 4mm to 5mm, such as the diameter before expansion is 74mm to 75mm, and the diameter after expansion can reach 78mm to 79m, special expansion height, separately required, set by the customer.3 inch plate inflatable shaft, usually using the inner diameter of the coil pipe is 76mm.

It can be applied to machinery with high winding precision or lighter winding items, such as: flexo printing machine, gravure machine, trademark printing machine, etc.; Applicable machinery includes: coating machine, leather machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, foaming machine, embossing machine, paper machine, non-woven machine, hot stamping machine, battery equipment and other related machinery supporting the use.

The slat-type inflatable shaft (air expansion shaft) is composed of two parts: the inflatable shaft (air expansion shaft) and the long expansion tile. The torque force of the expansion pad is adjusted by the inflation pressure, because the expansion pad is a long strip through the shaft because of its structure, and there is no section, so there is no slip function. The disadvantage of the slatted inflatable shaft (air shaft) is that there is no corresponding slip action due to the change of tension due to the material change when slitting multiple strips, which is easy to produce uneven winding, broken strips, loose coiling, and uncoiling, resulting in material loss. And the winding line speed is low. Adjusting the air pressure should be stopped, which will affect the work efficiency. The same shaft cannot receive large and small rolls at the same time.

The working principle of the slat inflatable shaft:

Plate inflatable shaft only need to provide its own air source, air pressure control in the range of 6-8kg/cm2, when the external parts need to be locked, as long as the air gun is inflated on the air nozzle on the plate inflatable shaft can be completed, the key bar will protrude against the external parts, when the paper needs to be relaxed, press the sliding air core on the air valve by hand to deflate, the key bar will return to the original appearance, and the external parts can be taken out to produce the slatted inflatable shaft.

5 advantages of tile type air shaft (slat air shaft):

1) The placement of the tile inflatable shaft (slatted inflatable shaft) is simple: compared with the key inflatable shaft, the placement of the plate inflatable shaft does not use most of the rules, and it can move and fix the paper core in any position on the shaft surface in terms of inflation and deflation action.

2) The tile type inflatable shaft (slatted inflatable shaft) is the longest lasting and easy to maintain: the inflatable shaft is a single part, and each part in its structure has a fixed specification, which can be interchangeable and convenient, making it easy to maintain.

3) The tile type air shaft (slat air shaft) is suitable for branch pipes of various widths and heights, and the practicability is very high.

4) The tile type inflatable shaft (slatted inflatable shaft) can carry heavier steel weight, and the radius of the shaft can also be flexibly determined according to the customer's needs.

5) The inflation time period of the tile type air shaft (slatted air shaft) can be completed in about three seconds, which greatly improves the work efficiency.

Customization of slatted inflatable shafts and keyed inflatable shafts:

The air shaft structure is generally made according to the needs of practical applications, there are no standard parts, and different types are selected according to the actual needs. The common types are aluminum alloy inflatable shaft, expansion key inflatable shaft and vane inflatable shaft, etc., and some distinguish between metal and non-metal. Large bearing weight: The size of the shaft diameter can be determined according to the actual needs of customers, and high-hard steel can be used to increase the bearing weight.

Previous: What Is The Difference Between A Cantilever Air Shaft And A Normal Inflatable Shaft

Next: What To Pay Attention To When Drawing An Air Expanded Shaft