Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

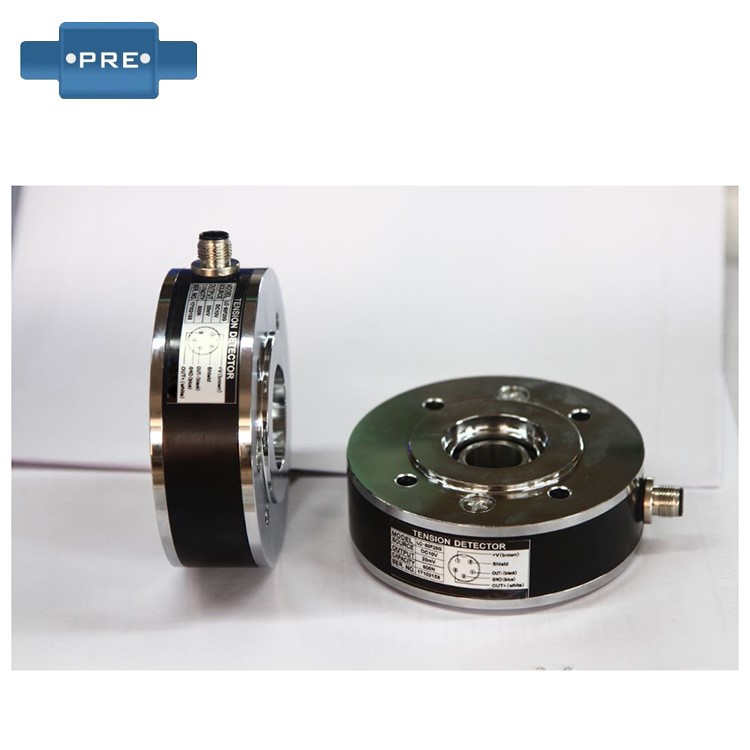

Tension sensor, also known as tension detector, is an instrument used to detect the tension of yarn in the process of tension control. Essentially, a tension sensor is also a load cell.

Structure and working principle of tension sensor:

The principle of the tension sensor is based on the load cell, using two tension transmission parts to transmit the force, the internal structure of the force sensor is fixed in the center area of the piezoelectric plate gasket on one side, the piezoelectric substrate is located between the edge of the other side and the force transmission part and close to the piezoelectric plate. Tension sensors can be divided into strain gauge type and micro-displacement type according to their working principle.

Strain gauge type tension transducers are tension strain gauges and compression strain gauges connected together in a bridge mode. The resistance value of the strain gauge will change with the change of external pressure, and the amount of change depends on the amount of pressure.

The micro displacement type tension sensor is to apply the load by external force, so that the leaf spring produces displacement, and then the tension is detected through the differential transformer, because the displacement of the leaf spring is extremely small, so it is called a micro displacement tension detector.

Here are some things to keep in mind when installing a tension sensor:

1) When installing the tension sensor, it is necessary to pay attention to the screw of the tension sensor can not be too long, the same is true for the bearing seat, and the screw can not be selected too long, otherwise it is easy to make the spring sheet of the tension sensor not work normally, so that the performance of the tension can not be detected.

2) When installing the tension sensor, it needs to be fixed with the side, and the screws that are too long can not be used when fixing, because if the screws are too long, it is easy to damage the internal measuring device of the tension sensor.

3) When installing the tension sensor, it is necessary to pay attention to the behavior that the tension sensor cannot be subjected to violent impact, otherwise it is easy to damage the tension sensor.

4) After the installation of the tension sensor, it is necessary to pay attention to the all-round inspection, so as not to miss the place, or in the installation process, do not pay attention to some places are damaged, only after the detailed inspection, in order to ensure the effective operation of the tension sensor.

The selection of tension transducers is mainly based on the following specific factors:

1) Determine the type of sensor according to the measurement object and measurement environment

In order to carry out a specific measurement work, it is necessary to first consider the principle of the sensor, which needs to be determined after analyzing many factors. Because, even for the measurement of the same physical quantity, there are multiple principles of sensors to choose from, which principle of the sensor is more suitable, according to the characteristics of the measurement and the use of the sensor conditions need to consider the following specific issues: the size of the range; The requirements of the measured position for the volume of the sensor; whether the measurement method is contact or non-contact; Signal extraction method, wired or non-contact measurement; The source of the sensor, domestic or imported, whether the price is affordable, or self-developed.

After considering the above questions, it is possible to determine which type of sensor to use, and then consider the specific performance indicators of the sensor.

2) Selection of sensitivity

In general, within the linear range of the sensor, the higher the sensitivity of the sensor, the better. This is because only when the sensitivity is high, the value of the output signal corresponding to the change to be measured is relatively large, which is conducive to signal processing. However, it should be noted that the sensitivity of the sensor is high, and the external noise that is not related to the measurement is also easy to mix, and will also be amplified by the amplification system, affecting the measurement accuracy. Therefore, it is required that the sensor itself should have a high signal-to-noise ratio to minimize the factory disturbance signal introduced from the outside world.

The sensitivity of the sensor is directional. When the measured quantity is a single vector and its directionality is required to be high, the sensor with low sensitivity in other directions should be selected; If the measurement is a multi-dimensional vector, the smaller the cross-sensitivity of the sensor, the better.

3) Frequency response characteristics

The frequency response characteristics of the sensor determine the frequency range to be measured, and the measurement conditions must be maintained without distortion within the allowable frequency range, in fact, there is always a certain delay in the response of the sensor, and the shorter the delay time, the better.

The frequency response of the sensor is high, and the frequency range of the measurable signal is wide, while due to the influence of structural characteristics, the inertia of the mechanical system is larger, and the frequency of the signal that can be measured by the sensor with low frequency is low.

In dynamic measurements, the response characteristics should be based on the characteristics of the signal (steady-state, transient, random, etc.) to avoid over-fire errors.

4) Linear range

The linear range of a sensor is the range in which the output is proportional to the input. Theoretically, the sensitivity remains constant within this range. The wider the linear range of the sensor, the greater the measuring range and the guaranteed measurement accuracy. When selecting a sensor, when the type of sensor is determined, the first thing to see is whether its range meets the requirements.

But in reality, no sensor can guarantee absolute linearity, and its linearity is also relative. When the required measurement accuracy is relatively low, within a certain range, the sensor with a small nonlinear error can be approximately regarded as linear, which will bring great convenience to the measurement.

5) Stability

The ability of a sensor to remain unchanged after a period of use is called stability. In addition to the structure of the sensor itself, the factors that affect the long-term stability of the sensor are mainly the environment in which the sensor is used. Therefore, in order for the sensor to have good stability, the sensor must have strong environmental adaptability.

Before selecting a sensor, it is necessary to investigate the environment in which it will be used, and select the appropriate sensor according to the specific environment in which it will be used, or take appropriate measures to reduce the impact of the environment.

There are quantitative indicators for the stability of the sensor, and after the expiration of the service life, it should be recalibrated before use to determine if the performance of the sensor has changed.

In some occasions where the sensor is required to be used for a long time and cannot be easily replaced or calibrated, the stability of the selected sensor is more stringent and can withstand the test for a long time.

6) Accuracy

Accuracy is an important performance index of the sensor, and it is an important link related to the measurement accuracy of the whole measurement system. The higher the accuracy of the sensor, the more expensive it is, so the accuracy of the sensor only needs to meet the accuracy requirements of the entire measurement system, and it is not necessary to choose too high. This makes it possible to choose between a number of sensors that meet the same measurement purpose, which is relatively inexpensive and simple.

If the purpose of measurement is qualitative analysis, it is sufficient to choose a sensor with high repeatability, and it is not appropriate to choose a sensor with high absolute accuracy; If precise measured values are necessary for quantitative analysis, sensors with the required accuracy class are required.

Applications for Tension Sensors:

Tension sensors are already widely used in many industries today, especially in the field of industrial production measurement. The advantages of tension sensors are that they are simple to install, easy to use, and suitable for crane scales, weighing machines, retrofit scales and electronic force measurement systems. Annular tension sensor plates are more suitable for a wide range, harsh working environment, good frequency response because of the same name, many are used in building materials, cement, chemical industry, lifting, lifting, etc. In addition, tension sensors are also used in machines in the paper industry, pharmaceutical, chemical, food, steel mills, foil production plants, cable laying and sawmills, and are suitable for the use of high-quality hydraulic components and instruments in the batch processing industry.