Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The most troublesome problem of coil sheet in the production line is that the material is easy to move left and right on the production line and deviate in one direction due to the speed, tensile force or uneven thickness of the material and various mechanical damage, resulting in the processing action in the middle section is not easy to cooperate. Or the sending and receiving action of the front and rear sections is uneven, resulting in the loss of many materials and the difficulty of subsequent processing.

The function of the correction system: the edge web guide system has the functions of automatic detection, automatic tracking, automatic adjustment, etc., to ensure the neatness of material winding, slitting and detection. The system is widely used in light industry, textile, printing and dyeing, printing and other industries, with the correction instrument can detect the edge position or mark line position of paper, film, self-adhesive tape, metal foil and other materials, and can control the horizontal position of the material in the transmission process, with high resolution, good stability, fast response, strong anti-interference ability, simple structure and other advantages. Web guiding systems introduce you to web guiding systems for web guiding applications on narrow web and nonwovens.

The working principle of the web guiding system: the correction control system is an automatic closed-loop system that automatically corrects the lateral deviation of the coil, detects the relative position of the edge of the coil through the correction sensor, and then controls the system to compare the deviation of the detected value and the set value, and sends a signal to the electric drive for correction;

In layman's terms, the sensor senses the material and transmits the signal to the controller, and the controller controls the motor to drive the guide roller or screw rod for deviation correction.

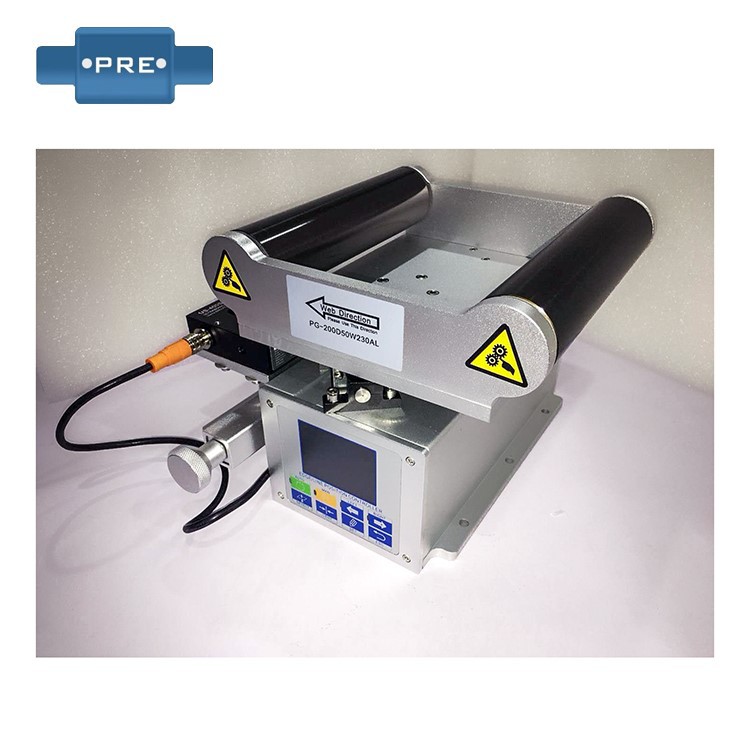

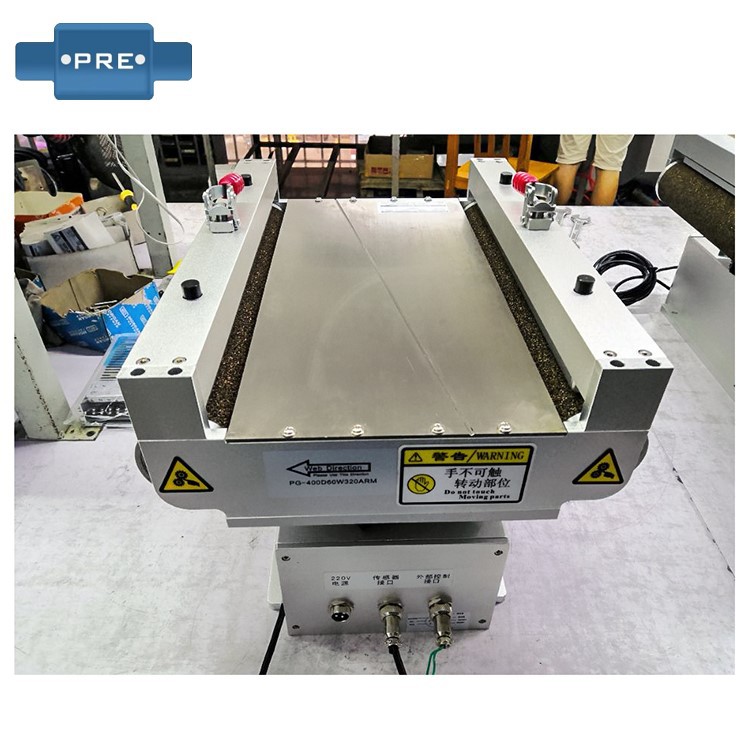

The correction control system is often classified as: deviation correction split machine and deviation correction integrated machine. The structure mainly includes: sensor, controller and actuator. Sensors are divided into: photoelectric sensors, ultrasonic sensors, CCD sensors, etc. Actuators form actuators of different specifications according to different strokes and thrusts. The controller is divided into different styles according to the communication mode and display mode

There are two problems required by the all-in-one web guider machine:

1) the idler device of the deviation correction all-in-one machine automatically corrects the deviation on both sides of a group of self-aligning rollers on the frame at the same height and arranges two vertically installed inspection and driving wheels, the rotating shaft of the inspection and driving wheel is connected with the power input shaft of the oil pump, the inspection and driving wheel and the oil pump on the left and right sides are fixed on the self-aligning roller support with two fixed brackets respectively, the tail of the composite oil cylinder is hinged with the fixed support, the piston rod of the composite oil cylinder is connected with the rotating part of the roller support of the self-aligning idler, and the oil port of the oil pump is connected with the tail of the composite oil cylinder with an oil pipe.

2) The idler device of the correction all-in-one machine automatically corrects the deviation when the belt deviates to the left, touches the oil pump on the left side of the inspection and drive wheel on the left side to quickly output the pressure oil, enters the rodless cavity of the oil cylinder through the oil circuit manifold block of the composite cylinder, pushes the piston and the piston rod rod, the hydraulic oil with the rod cavity returns to the oil tank of the oil cylinder through the oil circuit manifold, and the piston rod quickly stretches out, and pushes the self-aligning roller to rotate clockwise (that is, the left side of the self-aligning roller is deflected forward) to drive the belt to the right and center.

Characteristics of the split machine for guiding deviations:

1) High correction accuracy

The guide controller is equipped with a lever to effectively control the belt to operate within 10 mm of the frame centerline.

2) It is a good rectification effect

Compared with other kinds of mechanical and hydraulic correction devices, the significant feature of this device is that it guides the deviation at a certain distance in advance, so that the idler mechanism deflects a smaller angle to achieve the ideal correction effect, so that the belt wear is smaller, and the deviation correction effect is better.

3) Flexible operation and no maintenance

Since each swivel joint is designed with dry bearings, the unit is not eroded by water, slime, dust and other substances, and requires simple installation and no routine maintenance.

4) Reliable use and long service life

The device does not require any power drive, and the running mechanism is a low moving pair, with short moving distance, small wear and long service life.

5) Universal parts and easy to replace

The idler pulley used in the equipment is the upper idler pulley of the in-line belt conveyor. Once the idler pulley is damaged, the user simply replaces his own idler pulley in use, reducing downtime.

6) Downward correction can protect the belt sag of the belt conveyor, and the correction accuracy can reach -5%.

Advantages of the web guiding control system:

First of all, it has high sensitivity and high-precision control capabilities, which can achieve precise adjustment of equipment in a short time.

Secondly, the controller has strong stability and reliability, and can operate stably for a long time, and will not affect the production process due to environmental changes or equipment failures.

In addition, the whole set of servo guiding controller manufacturers also has the characteristics of simple operation and convenient maintenance, which can provide users with a good experience.

Examples of servo guiding controllers in practical applications:

Web guidance control systems are used in a wide range of applications:

Applicable industries: printing, packaging, papermaking, non-woven fabrics, lithium batteries, solar energy, rubber tires, textiles, metallurgy, etc.

Applicable coil material: web paper, film, metal foil, film, leather, non-woven fabric, weaving and other winding materials.

Applicable Equipment:

Printing and packaging: flexo printing machine, gravure printing machine, rotary printing machine, label printing machine, slitting machine, coating machine, laminating machine, inspection machine, die-cutting machine, film blowing machine, bag making machine, etc.

Non-woven fabrics: sanitary cloth equipment, sanitary pad production line, baby diaper production line, medical accessories production line, etc.

Lithium battery: electrode piece coating machine, pole piece rolling mill, slitting machine, winding machine, etc.

Rubber tires: extruders, cord production lines, presses, cutting machines, molding machines, etc.

In practical applications, the whole set of servo guiding controllers has been widely used:

First of all, in the paper printing machinery, it can effectively solve the problem of paper deviation in the printing process and ensure the printing quality; The production equipment responsible for processing strip materials is equipped with a high-performance automatic web correction control system, which increases the production speed of the entire production line by at least five times without compromising the quality of the produced products. This ensures that the material does not deviate from the correct position, because even a small error can produce scrap that no company can afford.

Secondly, in the coating machinery, it can accurately control the position of the coating head, so that the coating is uniform and stable;

Thirdly, in the rubber production line, the guiding controller can keep the film in the correct position and ensure the quality of the product.

In short, the whole set of servo guiding controller manufacturers play an important role in various industries.

Daily maintenance and requirements of the guiding controller:

1) In order to ensure that the deviation correction controller is always in good technical condition and can be put into use at any time, reduce downtime, improve mechanical integrity and utilization, reduce mechanical wear, prolong service life, reduce mechanical operation and maintenance costs, and ensure safe production, it is necessary to strengthen the maintenance of mechanical equipment.

2) The maintenance of the correction controller must implement the principle of "emphasizing maintenance and prevention first", regularly and compulsorily maintain, and correctly handle the relationship between use, maintenance and repair. It is not allowed to only use and not raise, only repair but not raise.

3) All operators must do a good job of maintaining all types of machinery in accordance with machinery maintenance regulations and maintenance categories. In exceptional cases, maintenance can only be postponed with the approval of the person in charge of the project, but generally not more than half of the specified maintenance interval.

4) The maintenance of the correction controller should ensure the quality and be carried out item by item according to the specified items and requirements. Maintenance items, maintenance quality, and problems found during maintenance should be documented and reported to the department's dedicated personnel.

5) The maintenance personnel and maintenance department should achieve "three inspections and one delivery", constantly summarize the maintenance experience, and improve the quality of maintenance.

Previous: How Much Do You Know About Guiding Controllers in Industrial Production?

Next: How To Choose The Guide Roller And Sensor For The Web Guide System