Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Inflatable sleeve clamp (inflatable bulge): Inflatable sleeve is also called inflatable sleeve, or inflatable shaft expansion sleeve. Inflatable sleeve clamp: used to cooperate with 3-inch inflatable shaft (inflatable shaft with a diameter of 74 or 75), 3-inch inflatable shaft sleeve clamp, can roll raw materials with larger diameter of paper tube, can replace 6-inch inflatable shaft, can be rewinded and unwound larger diameter items, and has higher usability.

The structure of the inflatable sleeve clamp (inflatable drum): the inflatable sleeve is mainly composed of the front sleeve, the rear sleeve, the cylinder, the inner tube, the air bag, the convex key strip, the briquette, the spring and other parts. The expansion set is made of high-quality aluminum, with oxidized surface, high-quality airbags and fast inflators. Good sealing effect, long service life and easy maintenance.

Among them, the consumable accessories mainly include inflatable nozzles, key strips, air bags, briquettes, and springs. Therefore, when customizing the inflatable sleeve, you can purchase the corresponding consumable parts from the supplier, and the PRE China factory can supply a complete set of consumable accessories to the customer.

Meaning of inflatable nozzle/ air valves:

The inflatable drum is an accessory used in deflation and inflation, it mainly plays the function of inflating and deflating, because the inflatable shaft needs to be inflated or deflated often in the working process, first of all, the inflatable handle should be aligned with the inflatable shaft nozzle to inflat, and when deflating, it is necessary to slide the air core against the inflatable shaft nozzle to deflate, so that the key bar will return to the original appearance.

The opening position of the air valve in the inflatable shaft is generally close to the shaft head, the shaft head part, the shaft head port, etc.;

The function and characteristics of the inflatable nozzle:

1) The inflatable nozzle is the key part of the inflatable sleeve to expand and contract, by inflating the inflatable nozzle, the main part of the inflatable sleeve is expanded, so as to hold the reel tightly and realize the fixation of the reel.

2) The inflatable nozzle also has a sealing function to prevent gas leakage and ensure the normal operation of the inflatable sleeve.

3) The inflatable shaft is inflated with an air nozzle, which can be filled intact and time-saving, so the inflatable operation time is short. The fullness is also very powerful, which makes the inflatable shaft less likely to fail when it is running.

The function of the key strip/lug:

The key bar on the inflatable sleeve clamp is an important part in the mechanical equipment, which can produce a tight connection between the inflatable shaft and the support rod through precise processing and matching, so as to ensure the stability and safety of the equipment during operation. Its role is mainly as follows.

1) The key strip on the inflatable sleeve clamp can fix and prevent the inflatable shaft from deflecting during operation, ensure the correct fit and accuracy between various parts, and improve the accuracy and efficiency of mechanical equipment. This can effectively prevent deviations, vibrations and other problems during the operation of the equipment, so as to increase the stability and reliability of the equipment operation.

2) The key strip on the inflatable sleeve clamp can make a tight connection between the inflatable shaft and the support rod, so as to balance the bearing force and effectively disperse the force borne by each point. In this way, the equipment can avoid being subjected to uneven force during operation, so that the force of each component is balanced, and the high strength can be maintained for a long time, so as to reduce the occurrence of equipment failure.

3) The key strip on the inflatable sleeve clamp can also play a role in preventing damage to the equipment, once the equipment is overloaded or suddenly shut down for some reasons, it has a certain bearing capacity, can be subjected to a certain impact force without easy damage, and ensure the long-term stable operation of the equipment.

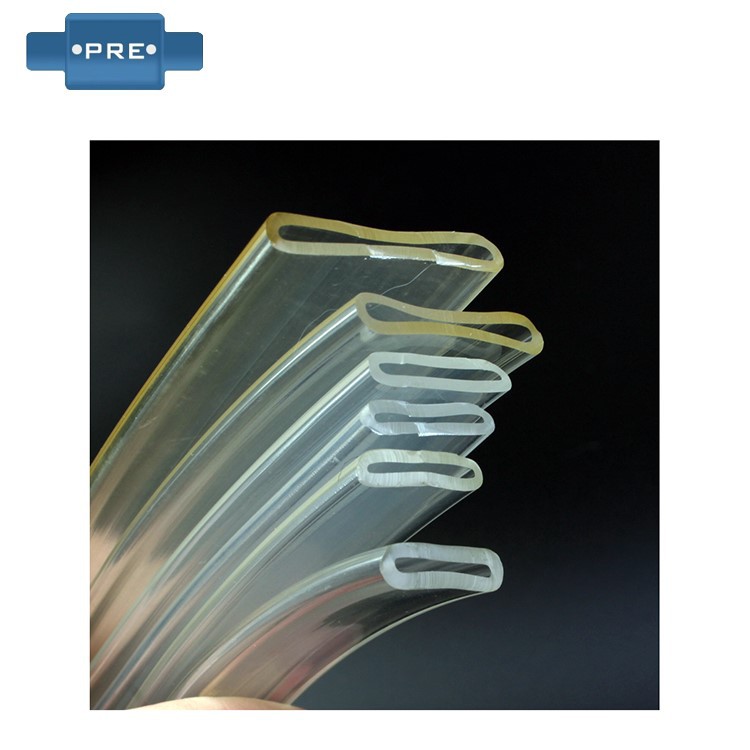

The role of the PU bladder/PU Flat Tube:

The airbag has the effect of equalizing the pressure so that it can evenly distribute the pressure.

How to replace the airbag:

1) Hang the keys on the inflatable drum shaft body with screws;

2) Remove the valve, and at the same time remove the screw on the shaft head at the end of the valve;

3) Then use a hammer and rod to knock out the shaft head;

4) Then take out the inflatable airbag, you can find out where the airbag is broken, compare it to the approximate position, what causes the puncture of the airbag and the leakage, whether there is a spring inside the puncture, if so, you must put the whole shaft vertically to get out all the residual springs, it is necessary to even remove each key for re-inspection or even install new springs;

5) Install the size of the old airbag and replace it with a new one, and press the two ends of the airbag tightly with an arresting machine;

6) Install the airbag into one end of the shaft head, then stuff the whole airbag into it, and then screw it into the shaft head;

7) Install the air valve, inflate and check whether the air valve is leaking, if not, remove all the screws on the shaft body, and repair an inflatable drum in this way.

The role of cover:

Briquetting on the inflatable shaft is one of the commonly used components in mechanical equipment, and its main function is to fix the inflatable shaft and make it move forward. In industrial production, inflatable shafts are widely used in various mechanical equipment and production lines, such as printing machines, paper processing equipment, etc. The inflatable shaft is an enclosed air compression device that allows for a secure positioning of paper or other materials without damaging the material.

The clamping and afterburner of the briquetting on the inflatable shaft ensures the position and tension of the paper and materials so that they can be processed smoothly during the production process. Not only that, but on special equipment such as printing presses, briquetting on the inflatable shaft can also help to adjust the speed and print quality. This makes the inflatable shaft a very important mechanical support device.

During production and processing, briquettes on the inflatable shaft are usually replaced and adjusted according to demand. These adjustments may be an adaptation to the dimensions of the material to be processed, or they may be to address some anomalies. In this case, briquetting on the inflatable shaft also ensures the stability of the production process and reduces machining misalignment and other problems caused by unsuitable pressures.

The role of springs:

The spring on the inflatable shaft is a common mechanical component, and its function is to stabilize the support and cushioning of the inflatable shaft. With the continuous development of industrial technology, the inflatable shaft has gradually become an indispensable and important component in the production and manufacturing, and the spring plays a vital role in it.

1) One of the functions of the springs on the inflatable shaft is to provide stable support. Inflatable shafts are a kind of flexible shafts, and they are often used in hydraulic machinery, textile machinery, printing machinery and other fields. When the inflatable shaft changes in the process of work, if there is a lack of sufficient support, it is easy to tilt or collapse, which will not only cause unnecessary losses to production, but also threaten the safety of workers. The flexibility and strength design of the spring structure can effectively support the inflatable shaft, thus bringing more stability to production.

2) The cushioning effect of the spring on the inflatable shaft is also very important. Under the conditions of high-speed rotation and high-frequency operation, the movement of the inflatable shaft will be affected by inertia and vibration, resulting in non-negligible impact and vibration forces. If there is no corresponding body cache software and hardware, it will not only affect the service life of the equipment, but also have a serious impact on the accuracy and efficiency of the production process. The flexible resistance of the spring on the inflatable shaft can effectively consume this impact force and vibration force, making the operation of the inflatable shaft more stable and reliable.

Previous: The Birth Of The Air Shaft Adapter