Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Definition of curved roll:

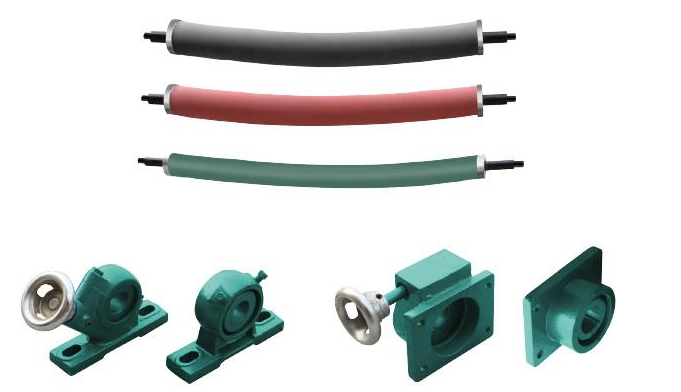

Curved rollers, also known as bending rollers or banana rollers, are used to stabilize sheet products in the production process, including paper sheets, fabrics, and nonwovens. The arc roller is roughly composed of three parts: the mandrel, the roll surface, and the support.

The mandrel is fixed when it works, and is the carrier of the whole roll, and the angle can be adjusted by support. The roller surface is composed of a series of roller sleeves, bearings, connectors, etc. that can be rotated briskly, and there will be a layer of rubber sleeve outside the curved roller of the rubber surface, and the rubber sleeve material and formula used are different according to different occasions.

The working principle of the curved roller:

Because the roll surface is curved, the contact area goes from short to long as the material passes through the high point of the arc, resulting in a force from the middle to the edge of the material. Thus playing a role in eliminating wrinkles.

The function of the curved roller:

It is to remove wrinkles on the page by stretching the format in different production processes. Similar to roll cladding products, the location and operating environment of the curved rolls need to be taken into account during the customization process, so that the long-term stability of the curved rolls can be guaranteed even in the most demanding environments. Customized curved rollers can be optimally adapted to a wide range of operating variables, such as operating speed and ambient temperature.

Classification of arc rolls:

The following materials are generally used for rubber sleeves according to different applications:

1. Nitrile rubber

Nitrile rubber can be widely used mainly because of its excellent comprehensive performance and relatively high cost performance, but the disadvantage is that the wear resistance and high temperature resistance are poor, so it is easy to age.

Suitable models are: slitting machine, coating machine, rewinding machine and other equipment in conventional environments.

2, EPDM rubber

The degree of temperature resistance and anti-aging is better than that of Ding Nile, and some of the properties are inferior.

3. Silicone

Silica gel has a stable molecular structure, its temperature resistance and wear resistance are outstanding, and because of its safe and non-toxic characteristics, it has an irreplaceable role in medicine, food and other fields.

Suitable models are: winding vacuum aluminizing machine, medicine, food machinery.

4. Polyurethane

The outstanding property of polyurethane is that it has super wear resistance, so it is more suitable for harder substrates, such as non-ferrous metals, steel, etc

Suitable models are: strip steel and aluminum strip seam separator

5, Teflon

Teflon rubber sleeve is commonly known as heat shrinkable tube, which has the characteristics of drug resistance, adhesive release, anti-static and so on.It is more suitable for the wet end of papermaking machinery, gluing and chemical environments.

How to customize a suitable arc roller, you need to pay attention to the following points:

1. Type of material

The type of material directly determines the choice of curved rolls, and hard materials will definitely cause wear and tear on relatively soft objects. So so

For newsprint, printing paper can choose metal curved rollers, while film, capacitive film and some other films need to choose glue

The Shore hardness of the rubber surface should also be adjusted differently according to different materials, so as not to wear the material or damage the rubber surface

Suitable. Some metal sheets, etc., can choose polyurethane materials.

In some occasions where bonding is required, a Teflon sleeve or spray coating is required.

Pharmaceutical, chemical corrosion and other environments usually require special treatment, and stable materials such as silica gel can be selected.

2. Device type

The type of equipment also has a considerable relationship with the choice of curved roller, the type of machine, the speed of the vehicle and the working environment. compare

Such as high and low temperature, fast speed, etc.

3. Size customization

After understanding the above two conditions, a most suitable arc roll also needs the appropriate size, according to the material of different widths,

The installation space of the equipment is individually customized.

4. Parameter configuration

1) A good arc roller needs to have the condition to achieve the best flattening effect within the working speed range

The impact on material equipment is minimized. For example, in the working speed range of high-precision equipment, the runout should not be higher than 10 rolls

The overall diameter difference of the surface should not be higher than 5, the whole is extremely smooth, the transition is gentle, the rotation is flexible, and the inertia should be small enough and the mass

Light. And it has a fairly long service life.

2) The main selection parameters are:

5.The fastest and most direct way is to send the drawings to the Chinese factory PRE, let the factory analyze the drawings, and communicate with you to make them directly.