Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

There are two commonly used types of web guide machines:

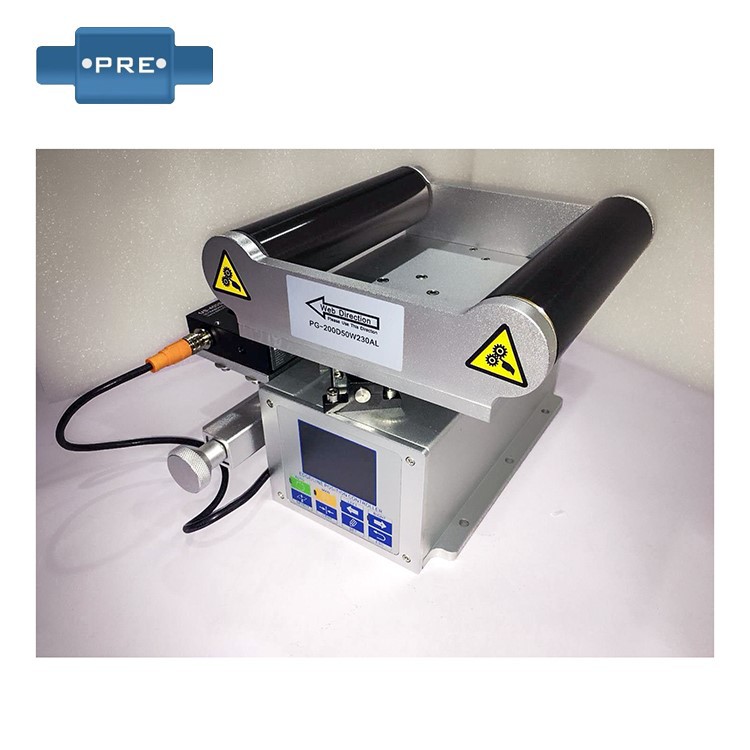

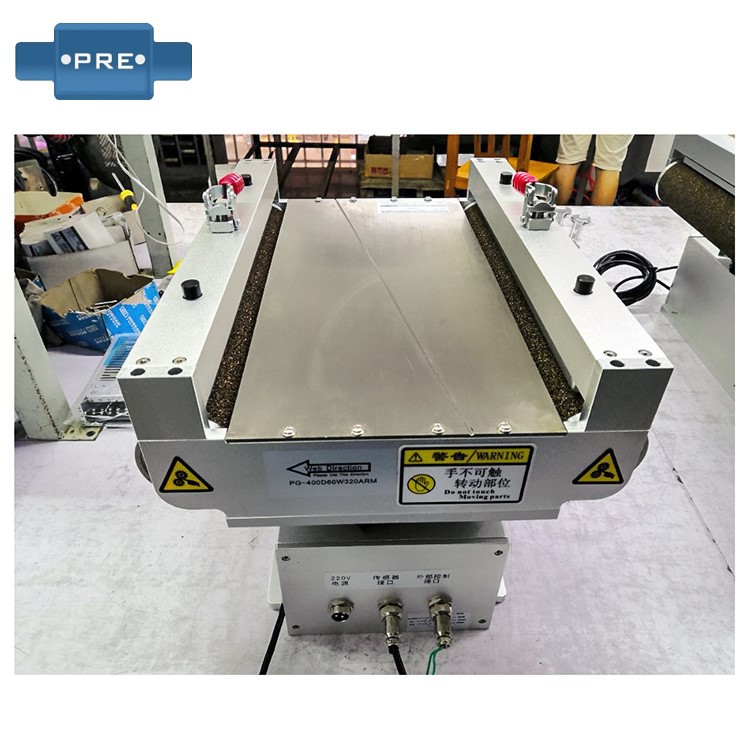

The most commonly used types of correction machines are servo linear correction machine (deviation correction split machine) and servo intermediate guide correction machine (deviation correction integrated machine). The style and function of these two kinds of correction machines are the same, they are used to correct the role of materials, but the installation methods are different, and the materials are relatively narrow, such as the width of the material is more than 600mm.

The main functions of the web correction machine:

The main function is to correct the coil and make your material more neat and beautiful.

• Used for multi-layer non-woven fabrics or other materials before composite, to keep the edges of the multi-layer materials neat after composite;

• It is used for printing materials before printing, especially for multi-color printing, to ensure that the materials do not shake and ensure the accuracy of color registration;

• After the unwinding position of the material, ensure that the material neatly enters the subsequent station of the production line;

• Before the winding position of the material, ensure that the winding edge of the finished product is neat.

Of course, whether the equipment needs to increase the correction machine, this depends on the product's receiving accuracy requirements, such as the requirements for neat and high accuracy of the receiving, you can find some professional manufacturers to contact the technical communication and then decide. Among them, the coil material in the coil material correction control system device refers to sheet products such as paper, film, foil, fiber, rubber, and braid.

Common machine areas for web guiding machines:

It is mainly used in the production lines of the most common rewinding and unwinding equipment, laminating machines, slitting machines, mask machines, packaging machinery, printing machinery, label equipment, paper processing equipment, plastic and rubber machinery, textile equipment, metal processing equipment, sanitary products production lines and other emerging industries.

The main guiding methods of the EPC guiding system of the Chinese factory PRE:

The correction system can be connected to a variety of different types of correction sensors and pushers, supporting EPC edge and LPC line, CPC alignment, SPS misalignment (snake) and other correction methods, using the color touch screen as a man-machine interface, easy to operate, beautiful and generous, with a setting wizard and online help system, even if you use the system for the first time, you can easily complete the basic settings.

Features of the EPC guiding system in the PRE Chinese factory:

1. Support three working modes: line chasing, edge chasing, and medium

2. Support photoelectric sensor, ultrasonic sensor, CCD sensor

3. Intelligent detection of sensor parameters, no need to calibrate the sensor in most environments

4. Automatic stroke measurement, no need for mechanical limit switch

5. Variable PI adjustment algorithm without overshoot integral, high precision, quick response and smaller error

6. Ultra-high-speed 500 microseconds (0.5 milliseconds) response speed

7. 12-bit AD sampling of analog sensor signal, 700,000 times per second sampling speed

8. FIR digital filter and differential filter are adopted, which has stronger anti-interference ability and more stable signal

9. The DC servo motor pushes the ball screw

10. All system status parameters are remembered when the power is off

11. Store 10 groups of different material parameters, and it is convenient and fast to switch materials

12. Chinese Simplified/Chinese Traditional/English trilingual menu operation

13. Humanized operation, fast and easy

14. Support Modbus bus and PLC/man-machine interface network control

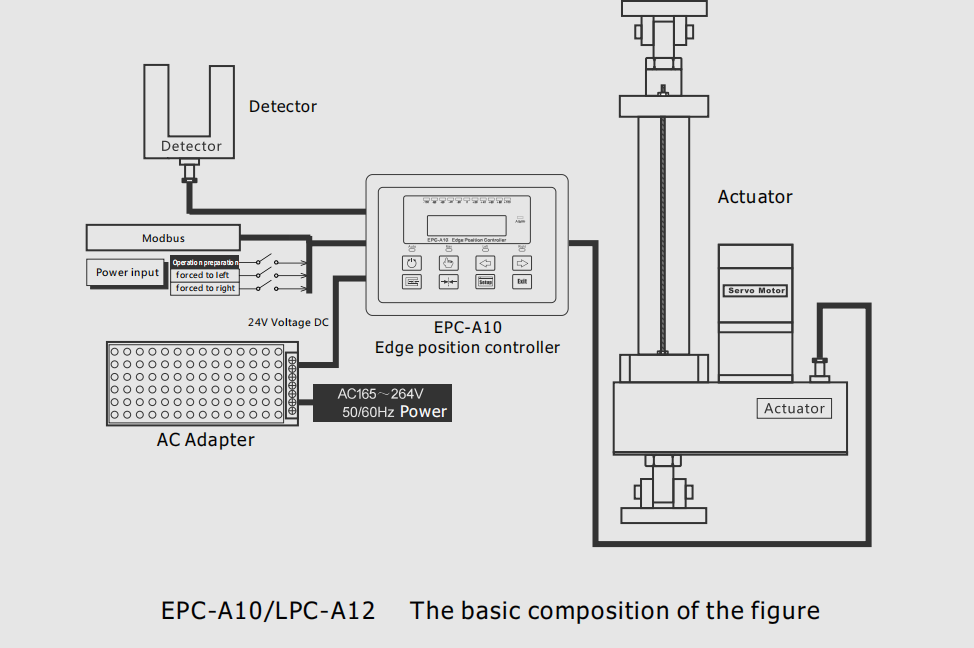

The working principle of the guiding system in the PRE Chinese factory:

• The first step is to detect the position of the edge or centerline of the material in real time.

• The second step is to send back the sensor signal: if the position of the material is offset, the sensor signal is transmitted back to the controller.

•The third step is to control the deviation correction: the controller judges the offset direction and degree of the material according to the received signal, and controls the thruster to promote the correction to rotate, so as to correct the deviation of the material.