Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

*When is a sheet type air expanding shaft suitable?

1. When the product needs to be slitted and rewound, and the width of a single rewinding product is narrow.

2. When the product requires a high true circle.

3. When the roll core or other materials used in the product have a thin wall thickness or poor quality and are easy to deform.

*Precautions when using slatted pneumatic shafts:

1. It is necessary to keep the air pressure in the leaf type inflatable shaft continuously sufficient.

2. Keep the surface of the pneumatic shaft clean to prevent deformation caused by deformation caused by debris stuck in the outer pressure plate.

3. The pneumatic shaft must be placed horizontally when not in use, and should not be suspended or erected, so as to avoid the deformation of the external pressure plate caused by collision.

4. Because the outer pressure plate is made of aluminum alloy, it is not suitable to be knocked with heavy objects when using it to prevent deformation.

5. When winding or unwinding, if there is a part at both ends that is not covered by the core, the empty core should be used to cover the vacant part.

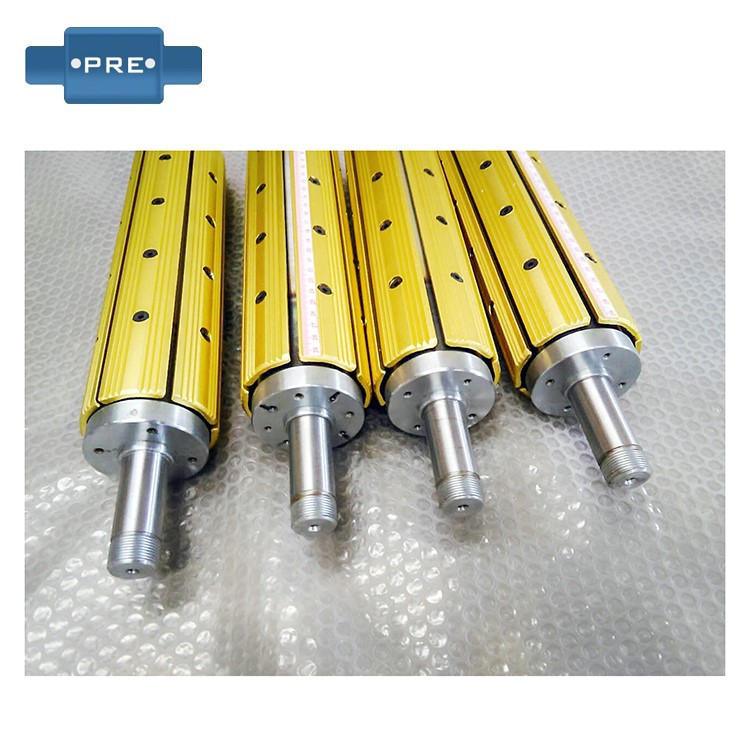

*Features of slatted core shaft:

1. The sealing effect of plate type inflatable shaft is good, the service life is long, the shaft head is detachable, and the maintenance is convenient. After inflation, the unilateral expansion height can reach 5mm to 6mm, such as the diameter before expansion is 74mm to 75mm, and the diameter after expansion can reach 79mm to 82mm. 3 inch key inflatable shaft, usually using coil tube inner diameter 76mm.

2. The strip inflatable shaft is easy to use, rewinding freely, and it only takes 2 seconds to inflate, which can complete the tight fixation of the inflatable shaft and the coiling tube, and achieve a good winding effect; Similarly, it only takes 2 seconds to deflect, which separates the inflatable shaft from the coil and makes it easy to remove the inflatable shaft from the coil. The inflatable shaft matching clamp is suitable for coiled pipes with large inner diameters, and is equipped with a safety chuck, which can make the folding between the inflatable shaft and the machine convenient and free, saving time, effort and cost. The development of the inflatable shaft is based on the original traditional shaft, and through continuous technological innovation, it has been sublimated into a modern inflatable shaft, which has brought the above related mechanical value to a new level.

The working principle of the slatted air expanded shaft:

The slatted inflatable shaft is the expansion of the airbag, which expands the aluminum alloy plate on the outer layer of the shaft to achieve the effect of expanding the coil. The slatted inflatable shaft is mainly composed of several aluminum alloy sheets meshed together, with a certain gap between each other, and an air bag in the middle. After inflation, the airbag expands, and the aluminum alloy sheet expands outward and hooks each other, so that it will not loosen, but it achieves the purpose of expansion and tightens the inner core of the coil.

*Application areas of plate type air shaft:

The plate inflatable shaft expands the whole plate, the fulcrum is evenly dispersed, and the force is uniform, which can be applied to the machinery with high winding precision or lighter winding items, for example: the inflatable shaft is mainly suitable for printing equipment: drying machine, flexo printing machine, concave machine, trademark printing machine, etc.; Other machinery includes: coating machine, leather machine, setting machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, cloth inspection machine, hot stamping machine, battery equipment and other related machinery supporting the use. It is especially suitable for occasions with high roundness requirements for paper tubes or the use of surface rewinding and unwinding, which can effectively improve work efficiency and product quality.

*Solutions to common air leakage problems of slatted inflatable shafts:

1. The pressure ring is loose, which is relatively easy, just tighten the screws.

2. There is a gap in the sealing ring, which needs to be sealed with sealant.

3. The inflator is partially leaking, so you can replace it with a new valve.

4. If the hose is broken, there may be a quality problem with the hose itself, and the shaft head needs to be removed and replaced with a hose.

*How to choose the right inflatable shaft for your company's production machinery:

1. When customers choose an inflatable shaft, they need to consider many aspects, such as the use environment, working status, etc.;

2. If it is used for unwinding end, the total weight of the coil is not very heavy, you can choose the plate type inflatable shaft, if it is heavier, the key type inflatable shaft is more suitable;

3. For the winding end, if it is generally not very heavy, choose a plate inflatable shaft;

4. If the working environment will be in contact with corrosive objects, such as ozone sanitization, it is not recommended to use an inflatable shaft with rubber key strips; Stainless steel key bars and aluminum key bars can be used;

5. If it is installed on equipment like a round knife die-cutting machine, the cantilever inflatable shaft is selected, which can be rotated unilaterally, which is convenient for loading and unloading and improving efficiency.

Previous: Why Can The Air Expaned Shaft Of Chinese Manufacturers Be Cost-effective?

Next: What Is The Difference Between An Air Shaft And A Mechanical Shaft?