Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

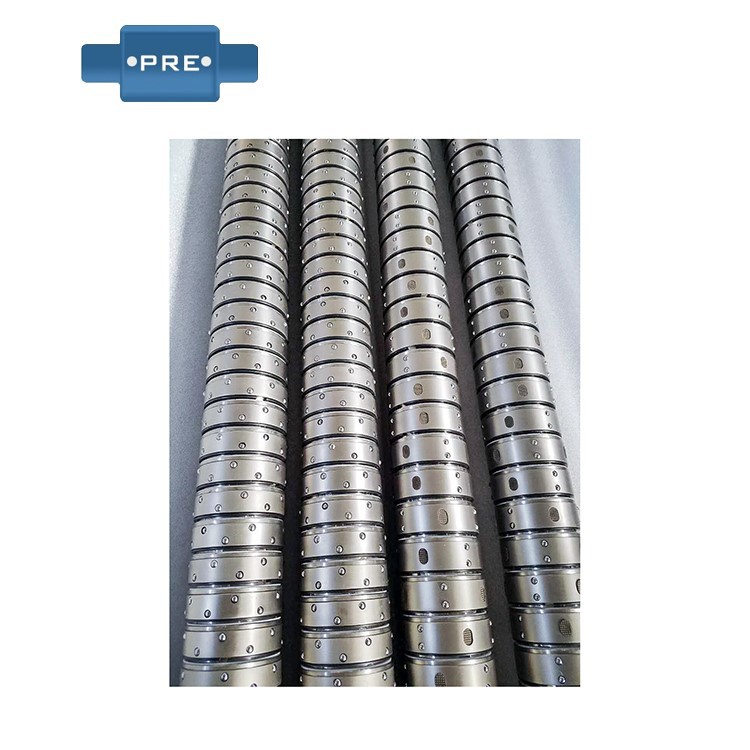

How the inflatable shaft works:

Although there are many names for inflatable shafts, they work on the same principle. The inflatable shaft and inflatable sleeve are very convenient and fast to use, only need to provide their own air source, the air pressure is controlled in the range of 6-8kg/cm2, when the external parts (such as the round paper tube) need to be locked, as long as the air gun is inflated on the air valve on the inflatable shaft, it can be completed, and the external parts (such as the round paper tube) can be taken out when the paper needs to be relaxed.

air expanded shaft maintenance method:

An inflatable shaft is a special shaft that is commonly used in industries such as textile equipment, printing presses, paper machines, etc. However, due to its sealing and processing difficulty, once a failure occurs, the difficulty and cost of maintenance will be relatively high.

1. Exhaust operation

When the inflatable shaft is flatulent and unbalanced or does not function properly, we first need to remove the gas (mostly gas or liquid) from it. Place the inflatable shaft in a dry place, open all the exhaust ports, and blow dry the inside of the inflatable shaft with hot air until all the gas has been expelled, otherwise it will lead to increased fragility of the material in the repair.

2.Check the surface of the shaft

Before repairing an inflatable shaft, make sure to inspect its surface for any damage or scratches. These scars can cause the inflatable shaft to not work properly or to have a reduced lifespan. Operations such as grinding, grinding and polishing the surface of the inflatable shaft are required before repairs can be carried out to ensure a smooth and flawless finish.

3.Replace Type 0 Seal Ring

When an inflatable shaft cannot be sealed, a Type 0 seal is usually one of the causes of damage. When replacing a Type 0 seal, care needs to be taken to select the correct size and material, and to ensure that the seal is installed in the correct location. Proper installation of the sealing ring not only ensures the sealing performance of the inflatable shaft, but also prolongs the service life.

4. Wash regularly

Since inflatable shafts are typically used to process fibers, paper, and other materials, they are susceptible to contamination by dust, fibers, and other impurities. These impurities can cause the inflatable shaft to not function properly or the machining results to be unsatisfactory. We need to clean the inflatable shaft regularly to ensure that its surface is smooth and avoid the influence of impurities.

5. Check the bearings and transmission

When an inflatable shaft does not rotate properly or produces noise, bearings and transmissions can be one of the causes. Check the quality and quantity of bearing components and take care to clean and lubricate fluids. For transmissions, we need to check that components such as gears, chains, and belts are normal and need to be replaced.

6. Carefully select the expansion tube (co-expansion tube or independent expansion tube)

By judging the type of structure of the inflatable shaft, we need to carefully select the appropriate type of expansion tube. Both co-expansion and independent expansion have their own advantages and disadvantages, and the needs of processing technology and product range need to be considered.

7. Manual stretch repair

When the inflatable shaft is bent or suspended, it is easy to cause the inflatable shaft to not work properly or cause greater wear. At this point, we need to use the method of manual stretch repair to solve the problem. These repair phases require attention to the accuracy of the tension and the correction of the shaft to ensure that the repaired inflatable shaft can function properly and remain stable.

8. Welding remedy

When there is obvious damage or defect on the surface of the inflatable shaft, we need to consider welding to repair it. Welding often requires consideration of material integrity and proper thermal control to avoid thermal distortion and other negative effects.

9. Post-coating treatment

After repairing the surface of the inflatable shaft, we can consider using a coating to protect its surface, which can avoid affecting its service life due to problems such as oxidation and corrosion. The application material should be matched to the inflatable shaft and should be abrasion-resistant, chemical-resistant, reliable and heat-resistant.

10. New inflatable shaft selection in special cases

In some cases, if the damage and repair of the inflatable shaft is severe, we can consider choosing a new inflatable shaft to replace the original damaged inflatable shaft. To ensure the reliability and fit of your new inflatable shaft, consider following the manufacturer's guidelines and recommendations. Special attention should also be paid to tightness and lubrication when installing new inflatable shafts

Repairing an inflatable shaft is a complex job, but it can ensure the normal use of the equipment and prolong the service life of the equipmentWe need to pay attention to accuracy, safety and quality of materials, follow the manufacturer's recommendations and refer to the above maintenance methods, which can help in the completion of the task or project.

Precautions for the use of inflatable shafts:

1. Pay attention to air tightness:

The transmission characteristics of the inflatable shaft depend on the load-bearing capacity of the gas, so the airtightness needs to be tightly controlled to prevent gas leakage. When selecting and installing the inflatable shaft, attention should be paid to the selection of high-quality airtight materials, and the strict installation of airtight rings, gaskets and pressure sensors to ensure that the gas does not leak, so as not to affect the transmission efficiency of the inflatable shaft.

2. Pay attention to the axial force balance:

The inflatable shaft generates an axial force during operation, and the magnitude of the axial force depends on the pressure of the gas and the shape of the ripples. In order to ensure the balance of the force transmission of the inflatable shaft, attention should be paid to selecting the appropriate air pressure size and corrugation shape to reduce the influence of the axial force on the workpiece.

3. Pay attention to the temperature and smoothness:

In the working process, the inflatable shaft will be affected by friction and gas pressure, so it is necessary to properly add smooth equipment such as lubricating oil and cooler to avoid excessive temperature and friction of the inflatable shaft, which will affect the transmission efficiency and equipment life.

Maintenance tips for inflatable shafts:

1. Keep it clean:

The inflatable shaft should generally be placed in a dry and dust-free place, and pay attention to the cleaning of the inside and outside of the shaft hole to ensure the smoothness of the air contact surface and maintain the air tightness.

2. Regular checks:

Regularly check the lubrication status, axial force, air tightness and other parameters of the inflatable shaft, and repair and replace abnormal parts in time.

3. Pay attention to moisturizing:

The inflatable shaft is generally not resistant to moisture, so attention should be paid to moisture prevention and heat preservation, and desiccant should be added regularly to ensure the normal operation of the inflatable shaft.

PRE factory from China briefly introduces the steps to disassemble the keybar air shaft:

Before disassembling the inflatable shaft, it is necessary to look at the structural diagram of the inflatable shaft before proceeding. First press the steel head of the inflator nozzle of the air shaft, drain the compressed air in the air shaft, and then remove the inflator nozzle. Use a diameter of 1-1.2mm iron wire to penetrate the small hole on the key bar along the circumferential direction of the air expansion axis, and the same circumferential direction is a group; Tie all the keys tightly. Avoid when the airbag is pulled out. The healthy bar falls into the aluminum alloy roller, which can also facilitate the installation of the airbag. And take out the positioning screws (M6 socket socket socket screws) and positioning sleeves that fix the two ends of the aluminum alloy roller and the air expansion shaft.

Need to process a screw for the pin puller, clamp the air expansion shaft on the lathe, usually like the contact surface between the inflatable end of the key bar air expansion shaft and the aluminum alloy roller will be coated with sealant, you should first use the gas welding gun and heat it first, and then when heating, other parts should be cooled to avoid the deformation of the aluminum alloy roller. Wait for the sealant to soften before pulling the end, as the airbag is attached to the inflatable end and the airbag will be easily pulled out.

Previous: What Determines The Load-bearing Capacity Of An Air Inflatable Shaft?

Next: What Are The Precautions For Inflatable Shaft Components?